Grass carp compound feed

A compound feed and grass carp technology, applied in animal feed, animal feed, application, etc., can solve the problems of grass carp mesenteric fat deposition, low protein conversion efficiency, high feed coefficient, etc., to facilitate large-scale promotion, improve quality and be edible ratio, the effect of reducing ammonia nitrogen emissions

Inactive Publication Date: 2010-08-25

SUN YAT SEN UNIV

View PDF2 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a method that can improve the growth and protein deposition rate of grass carp and reduce the feed coefficient and liver system number according to the problems of low protein conversion efficiency, high feed coefficient, and large amount of grass carp mesenteric fat deposition in the existing grass carp compound feed. Compound feed with whole fish fat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

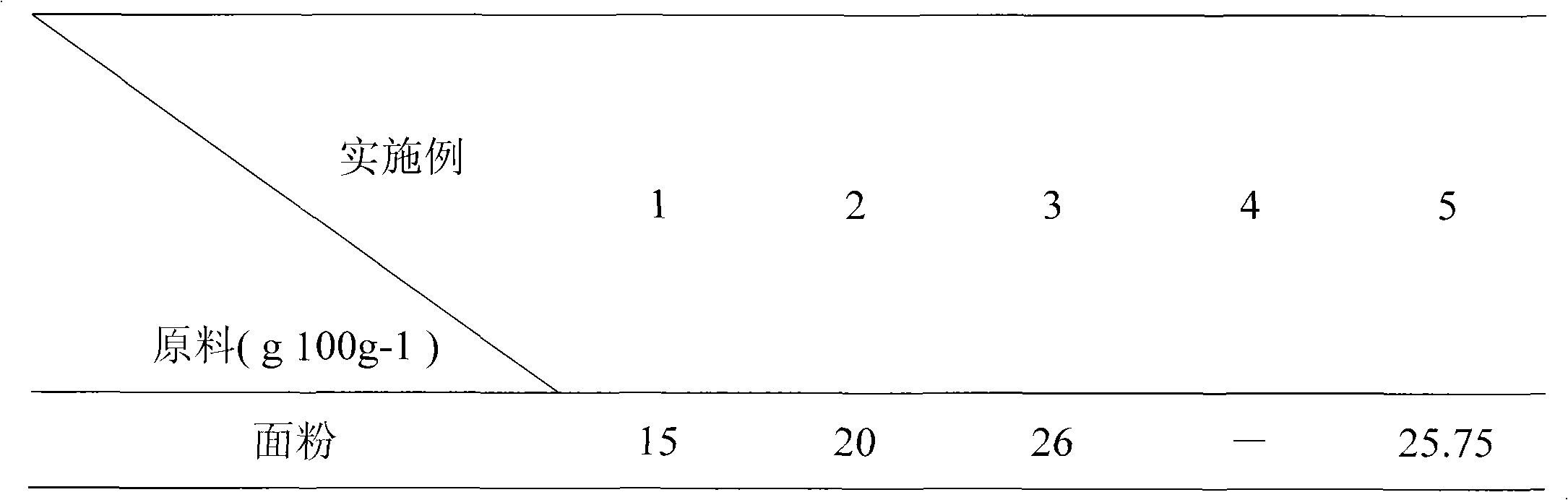

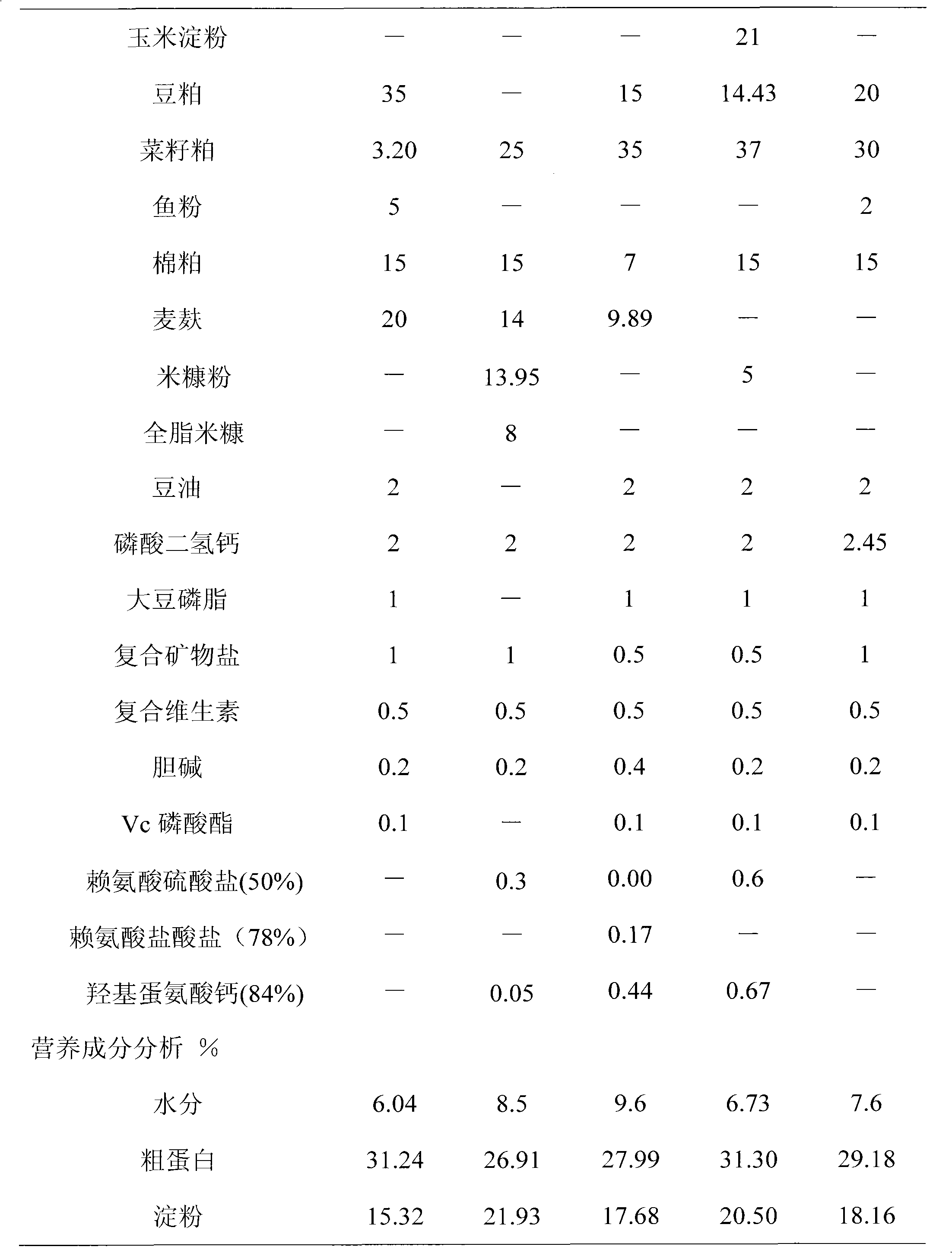

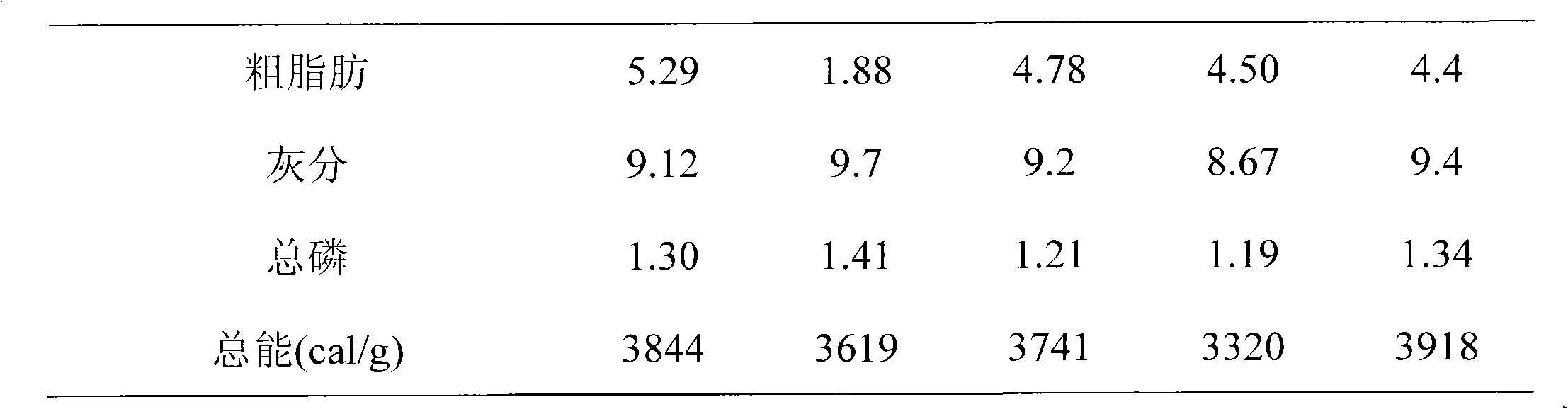

The invention discloses a grass carp compound feed which comprises the following nutrient components by mass percentage: 22-32 crude protein, 3-6 crude fat, 21-28 nitrogen free extract, 15-22 starch, 7-10 ash content, 6-10 water, 1.18-1.34 total phosphorus, 1.42-1.55 lysine and 5-8 crude fiber. The grass carp compound feed effectively solves the problems that in the existing grass carp culturing process, the protein conversion efficiency is low, the feed coefficient is high and a great deal of mesentery fat is accumulated, and improves the grass carp quality and edible proportion.

Description

technical field The invention relates to the field of grass carp feed, in particular to a compound feed capable of improving the growth and protein deposition rate of grass carp and reducing feed coefficient, liver system coefficient and whole fish fat. Background technique Grass carp (Ctenopharyngodon idella) is widely distributed in rivers in the northeast, east, central and southern regions of China. Since the successful hatching in 1958 by artificial oxytocin insemination, grass carp has been introduced to various parts of the world in recent decades, such as Japan, Southeast Asia, Eastern Europe, and the United States, and has become a highly valued freshwater cultured fish. Grass carp is the second most productive fish in the world, and it is the main freshwater aquaculture fish in my country. In 2006, the output reached 3.96 million tons, accounting for 21% of the total freshwater fish and shrimp aquaculture output (China Fisheries Yearbook, 2006). At present, the u...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23K1/18A23K1/175

Inventor 刘永坚田丽霞阳会军甘炼梁键钧

Owner SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com