Tail gas filter for preparing gallium nitride by hydride or chloride vapor phase epitaxy

An exhaust gas filter and vapor phase epitaxy technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems affecting the quality of gallium nitride materials, and the exhaust gas filter for which gallium nitride has not yet been found. Eliminate the effect of gallium vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

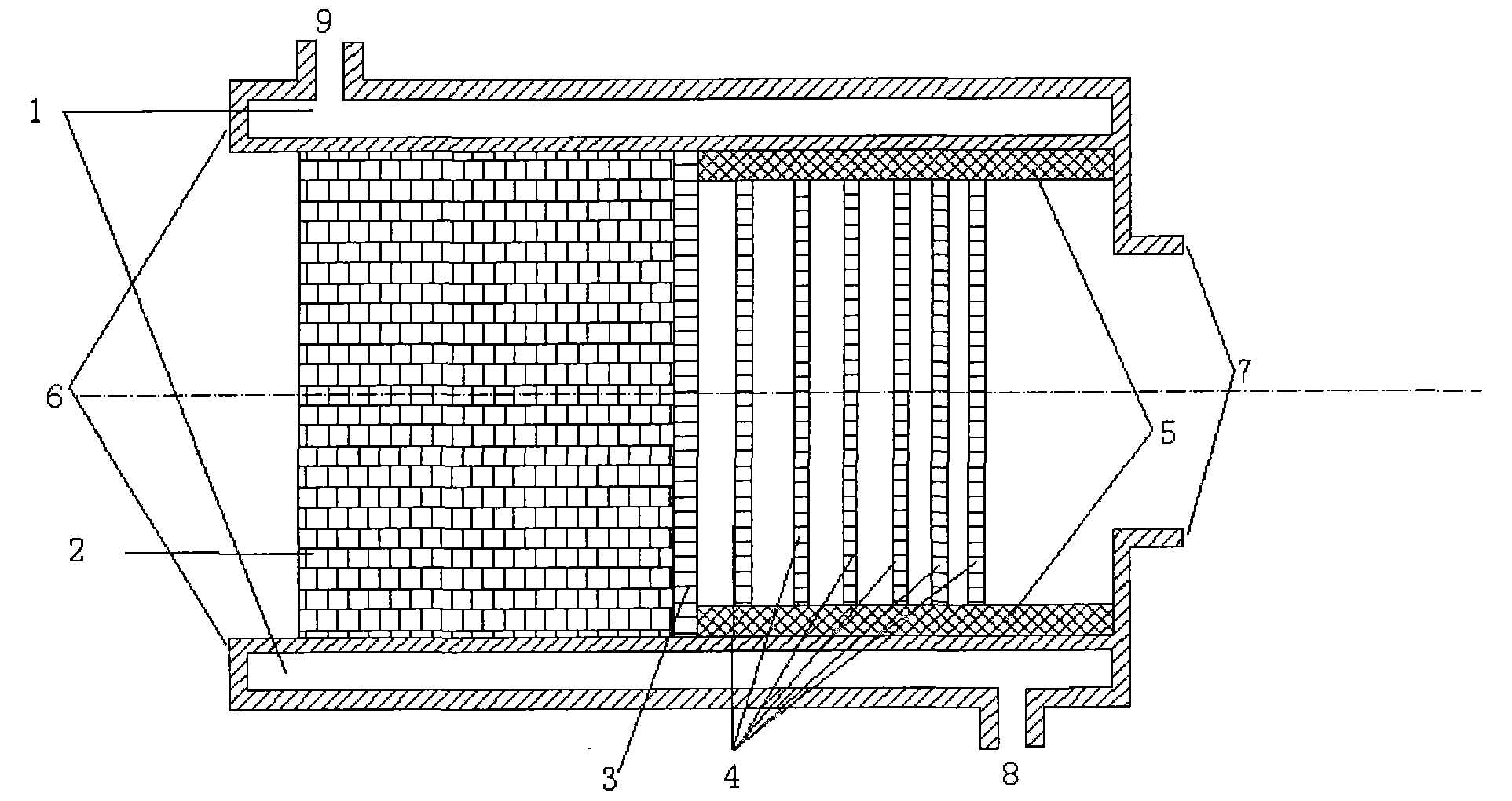

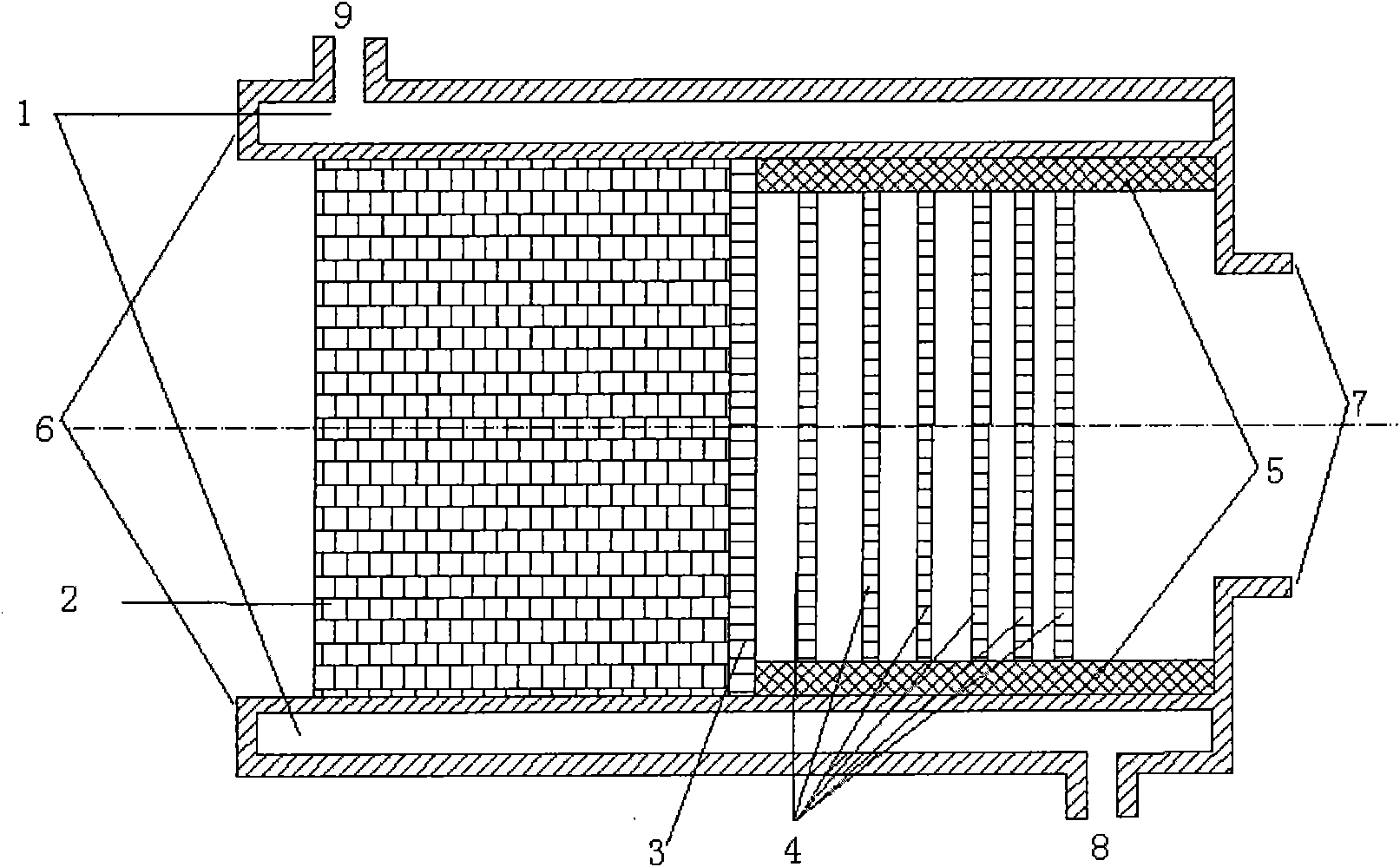

[0016] An exhaust gas filter for preparing gallium nitride by vapor phase epitaxy of hydride or chloride is composed of a shell 1, a plug 2, an isolation net 3, a screen 4 and a clamp 5, wherein the shell 1 is 500 mm in length, 400 mm in outer diameter and 400 mm in inner diameter 360mm cylindrical hollow water jacket, the outer diameter of the hollow water jacket cavity of the shell is 390mm and the inner diameter is 370mm, one end of the shell 1 is the filter air inlet 6, and the other end is the filter air outlet 7, which is fed by the filter One end of the air port 6 has a shell hollow water jacket water outlet 9, and one end close to the filter air outlet 6 has a shell hollow water jacket water inlet 8, the diameter of the filter air inlet 6 is 360mm, and the diameter of the filter air outlet 7 is 100mm, the diameter of the water outlet 9 of the shell hollow water jacket and the water inlet 8 of the shell hollow water jacket are both 15mm, and the plug 2 is a stainless ste...

Embodiment 2

[0019] Except that used stopper 2 is that the stainless steel model is the ball of 314 stainless steel wires, and screen cloth 4 is that aperture is the stainless steel wire mesh of 300 order models and is 314 stainless steel wire mesh, and screen cloth 4 has 8 layers altogether, other are all with embodiment 1.

Embodiment 3

[0021] Except that the screen cloth 4 used is the stainless steel wire mesh that the 400 object model is 314 in aperture, and the screen cloth 4 has 10 layers altogether, other are all the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com