Combined marine pollution-preventing system

An anti-pollution, ship technology, applied in ship construction, ship parts, water/sewage treatment, etc., can solve the problems of corroding ship pipelines, consuming large power and seawater, complex processes, etc., to reduce seawater consumption and reduce operation cost, and the effect of increasing chlorine production

Inactive Publication Date: 2010-08-25

DALIAN MARITIME UNIVERSITY

View PDF4 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. Use of low-sulfur fuel: Due to the limitation of earth resources, the storage capacity of low-sulfur fuel cannot meet the needs of shipping;

2. Fuel oil desulfurization: Due to the complex process and high operating cost, this method greatly increases the operating cost of the ship;

However, this method requires a large amount of electricity and seawater to directly electrolyze seawater. At the same time, the seawater after electrolysis is alkaline, which not only corrodes the ship's pipeline, but also requires further treatment before it can be discharged into the sea.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

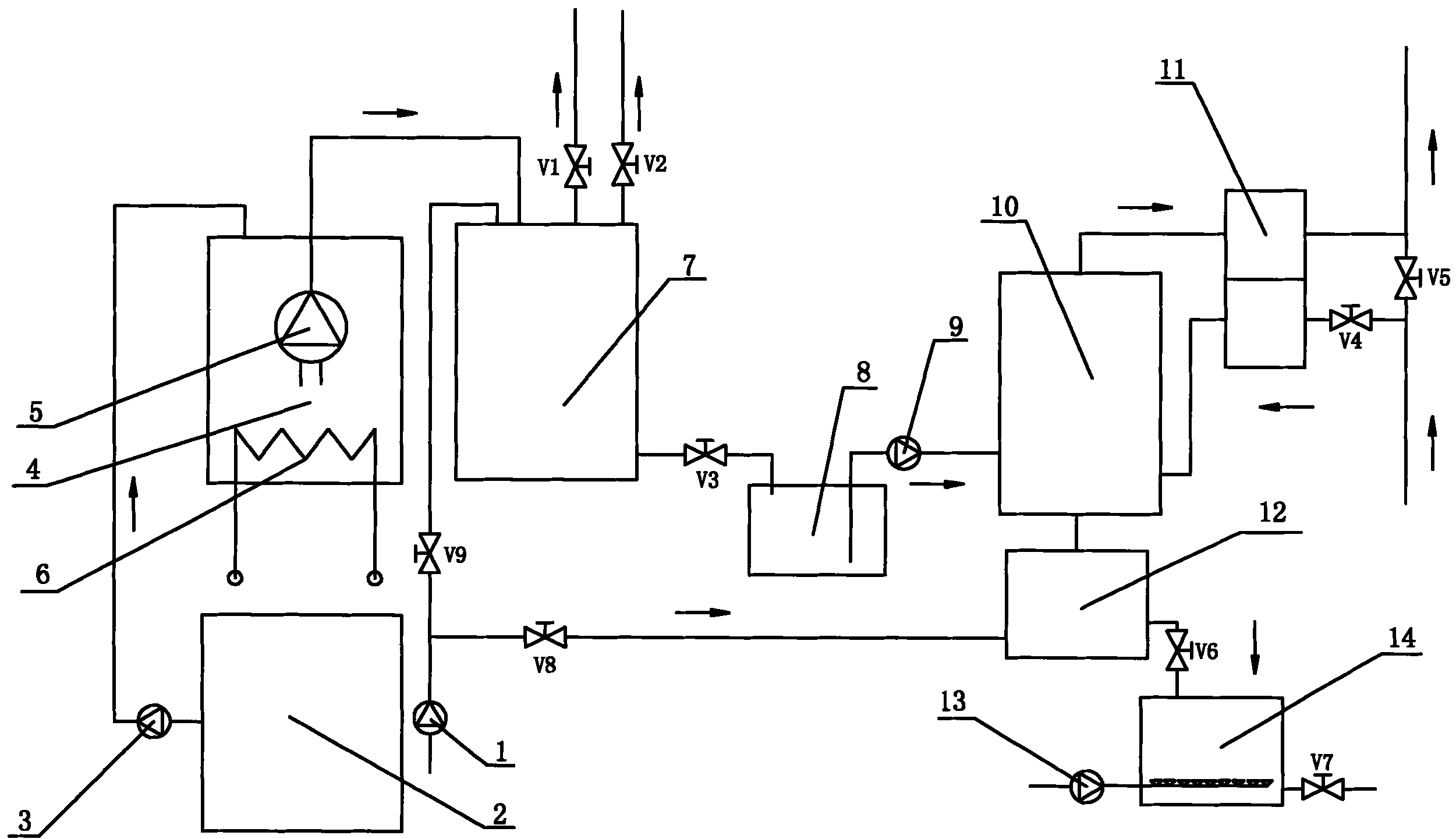

The invention discloses a combined marine pollution-preventing system, which comprises an electrolytic ballast water treatment system and an alkali water flue gas desulfurization system, an alkali water outlet of an electrolysis bath of the electrolytic ballast water treatment system is connected with a storage tank of the alkali water flue gas desulfurization system through a tube, and thereby the combined pollution-preventing system which can simultaneously treat the ballast water of a ship and desulfurize the tail gas of the diesel engine of the ship is formed. Since the invention sufficiently utilizes the high-concentration salt water produced by a seawater distiller and the alkali water produced by the electrolytic ballast water treatment system, the chlorine yield of the electrolytic ballast water treatment system and the absorptivity of the alkali water flue gas desulfurization system are increased. Under the premise of ensuring the operation of the whole system, the usage of seawater is greatly reduced, consequently, the needed pump power is reduced, electric energy is saved, and the operation cost of the ship is reduced. The desulfurization rate can reach more than 95 percent, the equipment size can be reduced, and thereby the space of the ship is saved.

Description

technical field The invention relates to the technical field of ship anti-pollution, in particular to a combined anti-pollution system for ship ballast water treatment and ship diesel engine tail gas desulfurization. Background technique According to IMO data, ships emit SO x Reached 6.34 million tons, accounting for about 4% of the world's total emissions. Air pollution from ships has reached a level that cannot be ignored, especially in ports, straits and some sea areas with dense routes, and ship exhaust has even become the main source of pollution in this area. The 1997 International Conference on the Prevention of Air Pollution adopted the 1997 Protocol of the MARPOL Convention and 8 resolutions. The Protocol incorporated the "Rules for the Prevention of Air Pollution Caused by Ships" and made it Annex VI of the Convention. The supplementary regulations came into force in our country on August 23, 2006. MARPOL Annex VI for SO in Ship Exhaust Gas x Emission levels ar...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/78B01D53/50C02F1/00C02F1/461C25B1/46B63J4/00

CPCY02P20/10

Inventor 董景明潘新祥

Owner DALIAN MARITIME UNIVERSITY

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com