Automatic assembly equipment for fixed torque bolt of splitting connecting rod

A technology for automatic assembly and cracking of connecting rods, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve few problems, and achieve the effect of convenient loading and unloading operations, ensuring reloading accuracy, and realizing reset meshing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following embodiments are given in conjunction with the accompanying drawings to further describe the device of the present invention in detail.

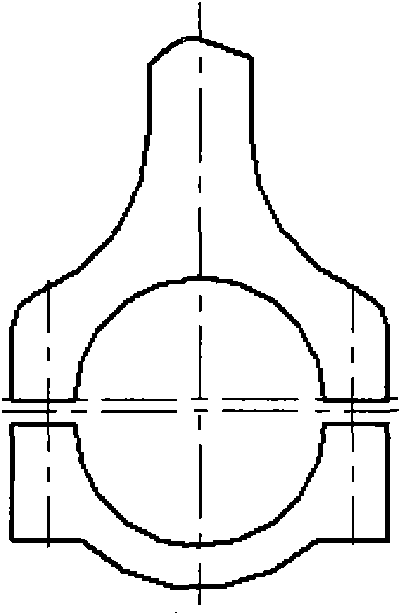

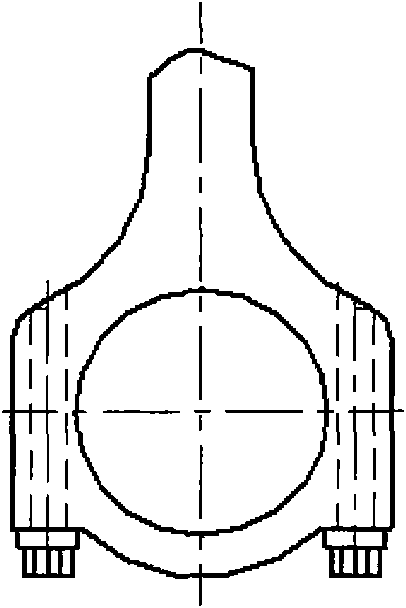

[0046] The invention provides an automatic assembly device for splitting connecting rod constant torque bolts. The device is composed of a mechanical system and a pneumatic system. The mechanical system includes a constant torque bolt tightening device and an automatic bolt tightening device.

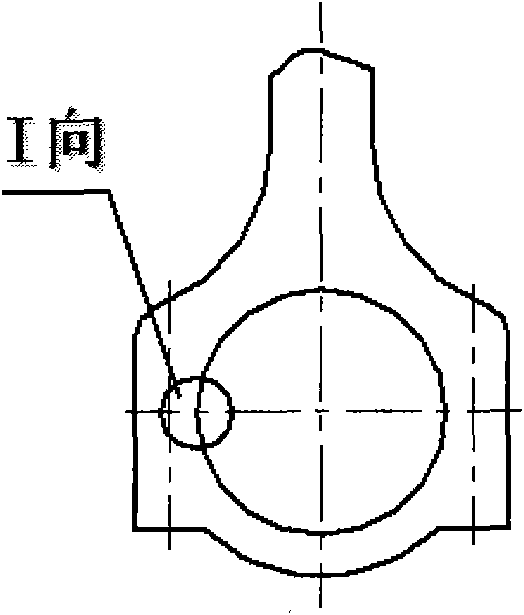

[0047] The fixed torque bolt tightening device includes a connecting rod positioning mechanism, a connecting rod swinging and pressing and vibrating slag removal mechanism, a connecting rod cover opening and closing mechanism, a constant torque wrench and a feeding mechanism, and a bolt rotating and guiding mechanism. Described positioning mechanism comprises big head hole positioning movable block 10, big head hole fixed block 11, connecting rod small end positioning block 2 and position adjustment mechanism; Big head hole fixed bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com