Special heavy concrete compensating weight of electrified railway contact network and manufacture method thereof

An electrified railway, heavy concrete technology, applied in railway vehicles, cable railways, overhead lines, etc., can solve the threat to the safe operation of power supply equipment and driving safety, can not effectively solve the phenomenon of iron falling weight theft, iron falling weight production High cost and operating cost, to solve the problem of theft, low operating cost, and low manufacturing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

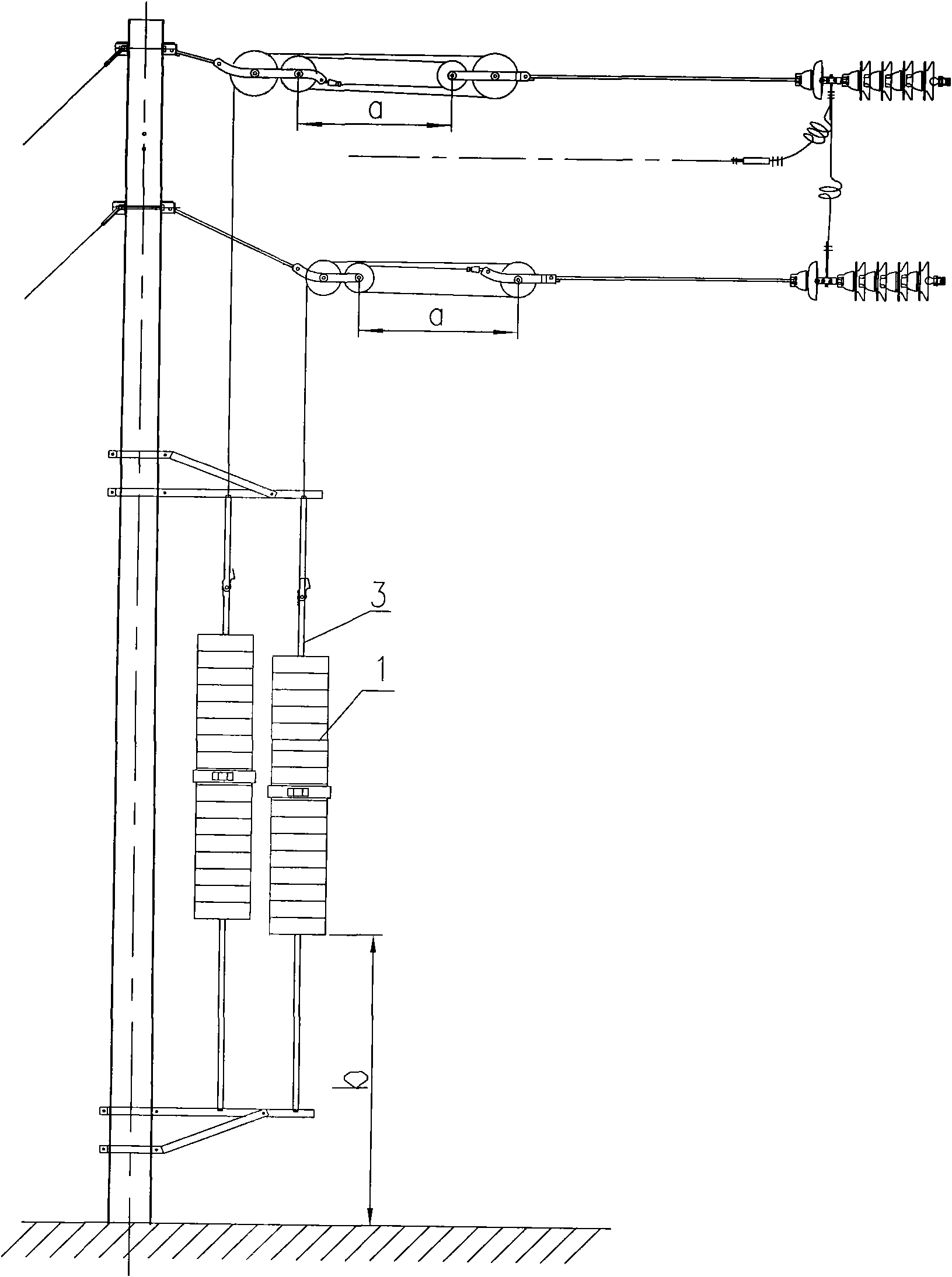

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] The manufacturing method of the special heavy concrete compensation pendant for electrified railway catenary is based on the processing and manufacturing method of reinforced concrete components, and its specific steps include:

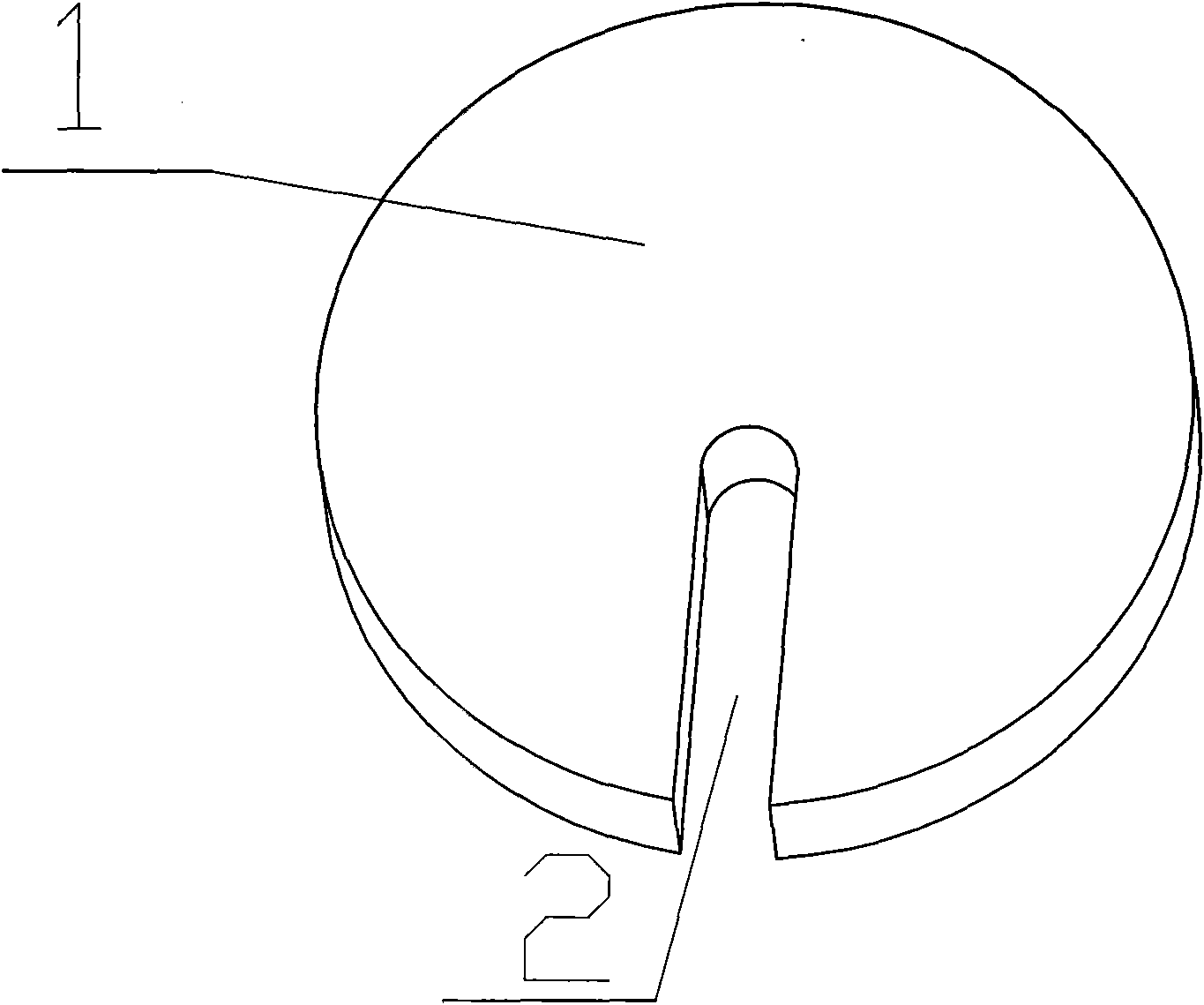

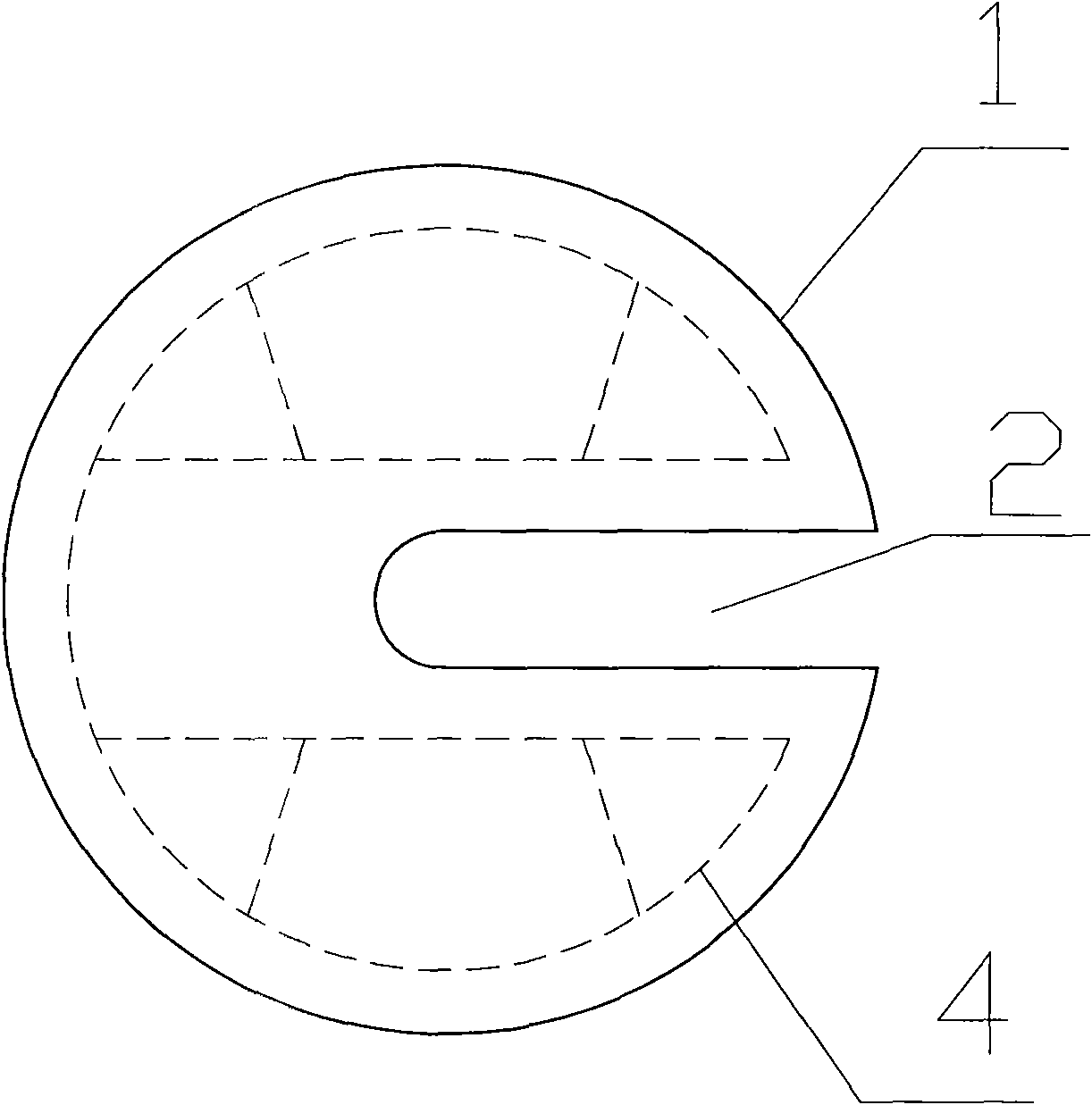

[0027] 1. Make the iron frame 4 and template according to the shape characteristics of the pendant. The template is brushed with a release agent to make the outer surface smoother. The iron frame is made of steel bars. The diameter of the steel bars is 6-10mm to meet the use requirements. The thin steel bars are folded into a shape suitable for the curved surface of the formwork, and its shape matches the size and shape of the weight. When making it, the steel bars are first bent into a frame, which is similar to a "C" shape, with one side open, and the opening part has a Two horizontal steel bars are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com