Method for analyzing and monitoring erosion of furnace lining of blast furnace

A technology of blast furnace lining and boundary integral equations, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems that cannot fully reflect the full state and erosion degree of the hearth, the limited number of ceramic or metal rods, and ultrasonic distortion, etc., to achieve The effect of good technical and economic indicators, saving calculation amount and prolonging the service life of blast furnace

Inactive Publication Date: 2010-08-25

WISDRI ENG & RES INC LTD

View PDF0 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the high temperature and harsh conditions of the hearth, ultrasonic waves are often distorted, and the number of ceramic or metal rods buried at the same time is limited, which cannot fully reflect the full state and erosion degree of the hearth

(2) Platinum resistance detection method. Although the detection accuracy of platinum resistance is high, it is expensive. It is generally used to detect low temperature data such as cooling water inlet and outlet temperatures.

(3) Heat flux density meter, generally used for offline detection of a certain part, rarely used for online continuous measurement

Although the above detection methods are feasible, they all estimate the corrosion of the furnace body by accumulating detection data. There are still many problems in the long-term stable operation, which need to be further improved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

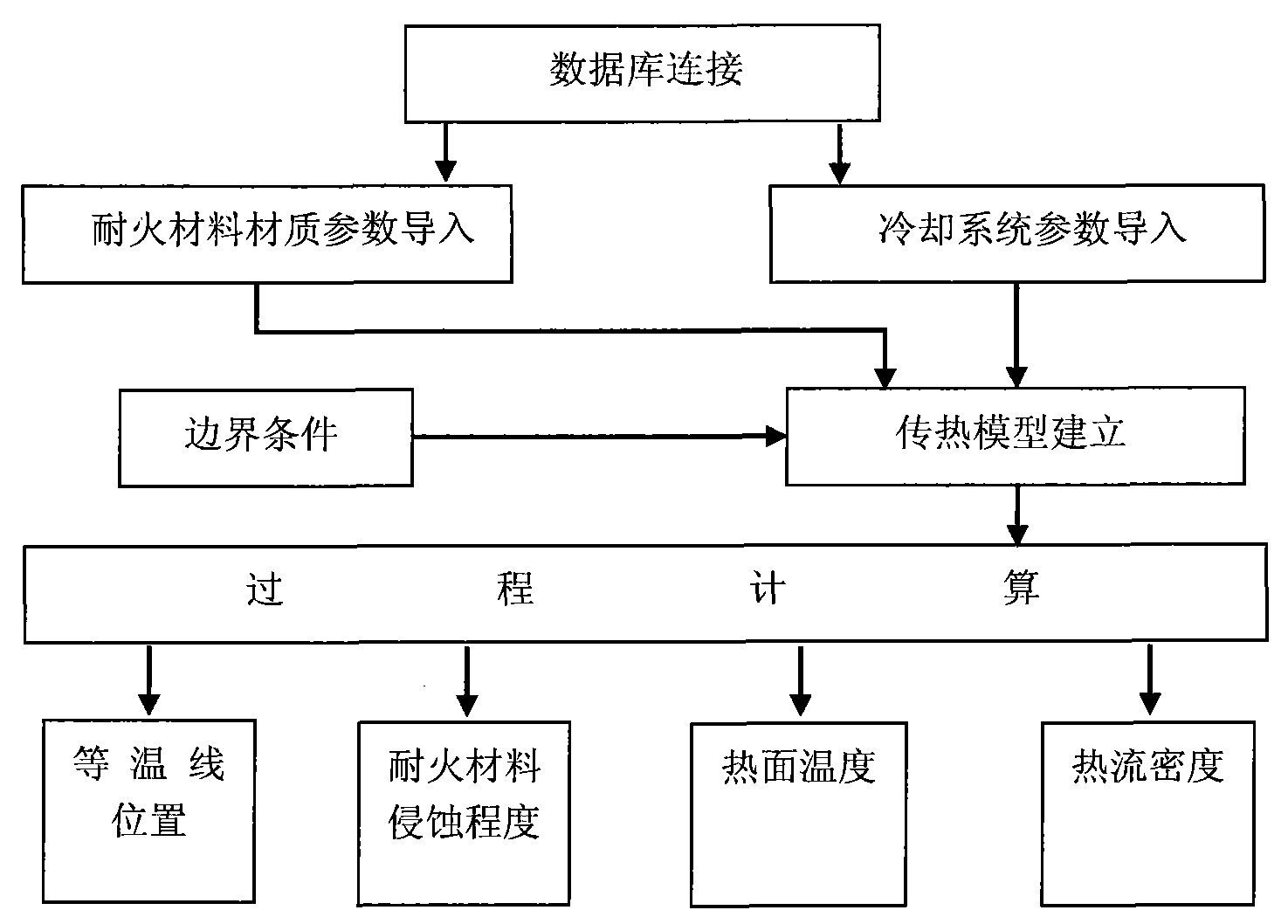

The invention provides a method for analyzing and monitoring the erosion of a furnace lining of a blast furnace, comprising the following steps of: (1) radially and uniformly arranging thermocouples along a furnace cylinder; (2) establishing database connection and introducing fire-resistant materials and cooling system parameters; (3) establishing a boundary condition and establishing a heat transfer model according to the introduced data in the step (2); (4) analyzing numeric values of the heat transfer model by using a computer according to measuring values of the thermocouples to finally acquire an isotherm position; and (5) writing a model calculation result into the database, displaying the change and the shape of the position of eroded boundary after the computer reads the database in real time, and storing the calculation result to form history data and history curves. The method avoids the quickening of the erosion speed and the ring crack of carbon bricks, simultaneously prevents the furnace cylinder from thickening to influence the smooth operation of the blast furnace, and further prevents piling of the centre of the furnace cylinder and the erosion phenomena of the boundary of the furnace cylinder and the furnace bottom; and simultaneously guides the operation of the blast furnace, in particular to adjustment of cooling water quantity, and ensures that heat flow intensity of the furnace cylinder and the furnace bottom is in the proper range.

Description

technical field The invention is used for on-line monitoring and analysis of lining erosion of ironmaking blast furnaces in the metallurgical industry, and provides necessary guidance for blast furnace operation. Background technique After the blast furnace was put into production, the working conditions of the hearth bottom were particularly bad. As the part containing high-temperature molten iron, the refractory lining was eroded by the physical and chemical effects of molten iron, and the erosion gradually increased with the service time. Repairing during the production process like other parts of the blast furnace is the main limiting link of the first-generation blast furnace. The study of lining erosion is of great significance to the safe production and economic and technical indicators of the blast furnace. At present, domestic iron and steel enterprises have three main methods for hearth bottom detection: (1) Ultrasonic detection method, that is, during the overh...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21B7/06C21B7/24G06F17/50

Inventor 周磊

Owner WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com