Spade heat-treatment medium recovering device and method for recovering medium using the device

A recovery device and medium technology, which is applied in the field of shovel heat treatment medium recovery device, can solve the problems of overflowing environment in the drying pool pharmaceutical industry, failure to dry normally, high recovery cost, etc., and achieve the effect of scientific structure design, small water consumption and convenient operation

Inactive Publication Date: 2010-08-25

付长智

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantages of this recycling method are:

②The drying process is limited by natural conditions, and it cannot be dried normally in rainy or snowy days, especially when heavy rain occurs, it is easy to cause the drying pool to overflow and cause the second environmental pollution;

③ Special personnel are required to be responsible for transportation, drying, concentration measurement, etc., and the recycling cost is relatively high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

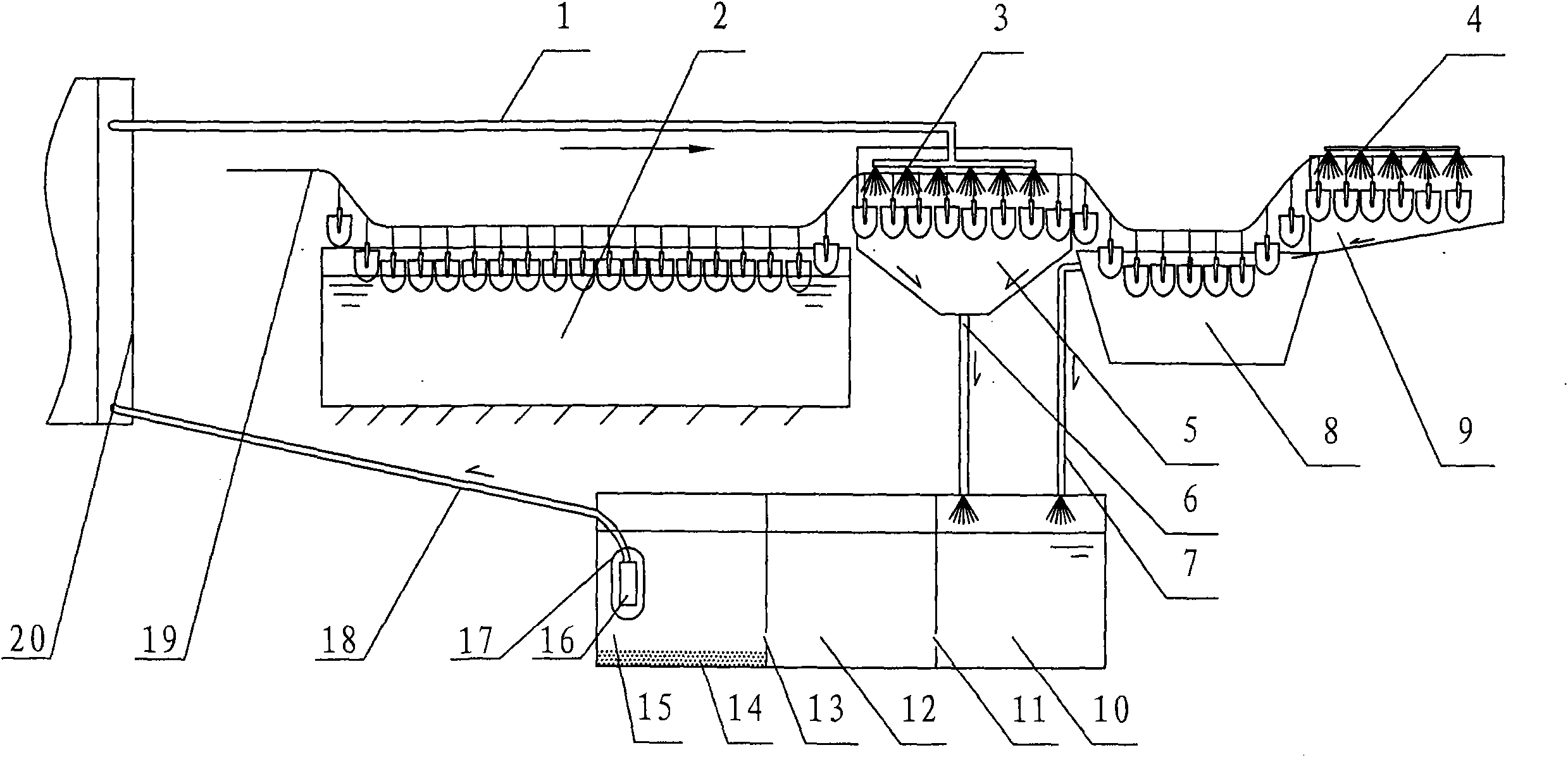

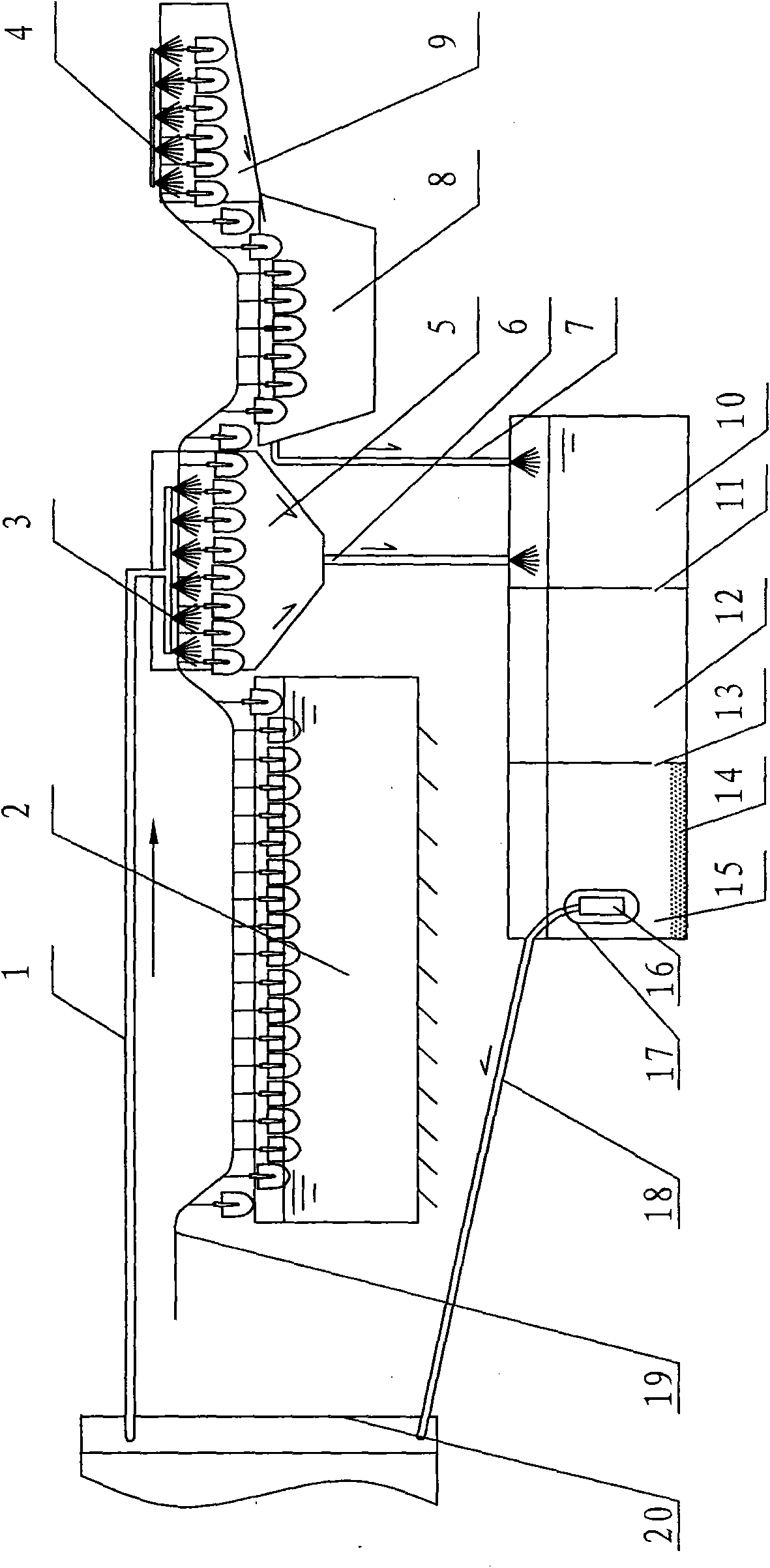

The invention relates to a spade heat-treatment medium recovery device and a method for recovering the medium using the device. The device comprises a conveying chain, a sprinkler device, a salt bath groove, a bleaching chamber, an immersing and diluting tank, a fresh water spray chamber and a three-level cooling pool. The salt bath groove is a heat-treatment iso-quenching bath provided with nitrate; the bleaching chamber for washing and diluting work pieces, the immersing and diluting tank and the fresh water spray chamber are arranged in a triangular shape, wherein the bottom of the bleaching chamber and the upper part of the immersing and diluting tank are provided with osculums of tail water in turn, and a washing recovery pipeline is communicated with an one-level recovering pool; three recovery pools constitute the three-level cooling pool which is arranged under the ground. The method comprises the steps of hoisting the work pieces on the conveying chain and entering the work pieces to the salt bath groove provided with the nitrate to carry out heat-treatment iso-quenching; then carrying out three-level washing and leading the fresh water tail water to enter the one-level recovery pool to be naturally cooled; and at last, recovering the medium in the three-level recovery pool. The invention has the advantages of convenient operation, saved energy, simple recovery process, closed circulated process and no pollution. The device can use the residual heat of a heating furnace.

Description

Device for recovering shovel heat treatment medium and method for recovering medium using the device technical field The invention relates to a device for cleaning and recovering heat treatment medium and a method for cleaning and recovering heat treatment medium using the device, in particular to a device for recovering shovel heat treatment medium and a method for recovering medium with the device. Background technique The media usually used for heat treatment include water, oil, salt, etc. When the surface of the workpiece to be treated needs to be coated with paint, plastic powder, etc., it is necessary to clean the residual heat treatment medium on the surface of the workpiece. Among them, most of the heat treatment wastewater containing salt medium contains nitrite, and direct discharge will cause serious pollution to the environment. Therefore, when cleaning the salt medium, in order to ensure the quality of the workpiece surface, the flowing water spraying process i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21D1/56C02F1/58

Inventor 付长智付宇轩

Owner 付长智

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com