Method for preventing internal oxidation layer in normalization treatment of electrical hot-rolled strip steel

A technology of inner oxide layer and normalization treatment, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as difficulty in implementation and increase production processes, eliminate furnace roll nodules, avoid cleaning work, and reduce costs. Effect

Active Publication Date: 2010-08-25

BAOSHAN IRON & STEEL CO LTD

View PDF1 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Japanese patent publication 2-149622 adopts the method of normalization after pickling, and reduces the inner oxide layer by eliminating the oxygen diffusion of the reduction of the outer oxide layer. This method increases the production process and is used in the continuous normalization pickling unit. difficult to implement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

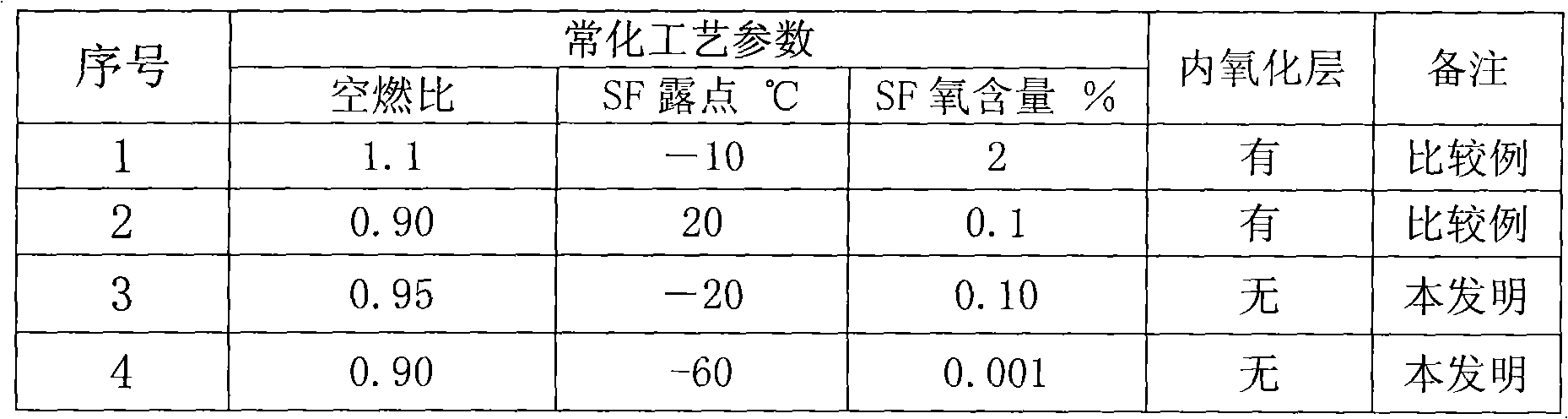

Embodiment 1

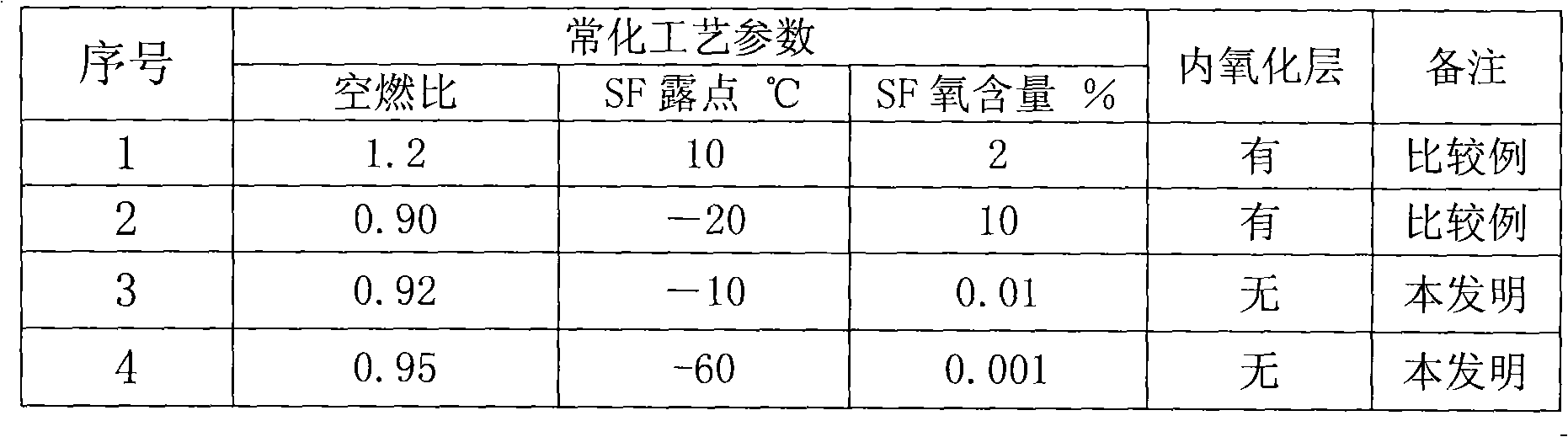

Embodiment 2

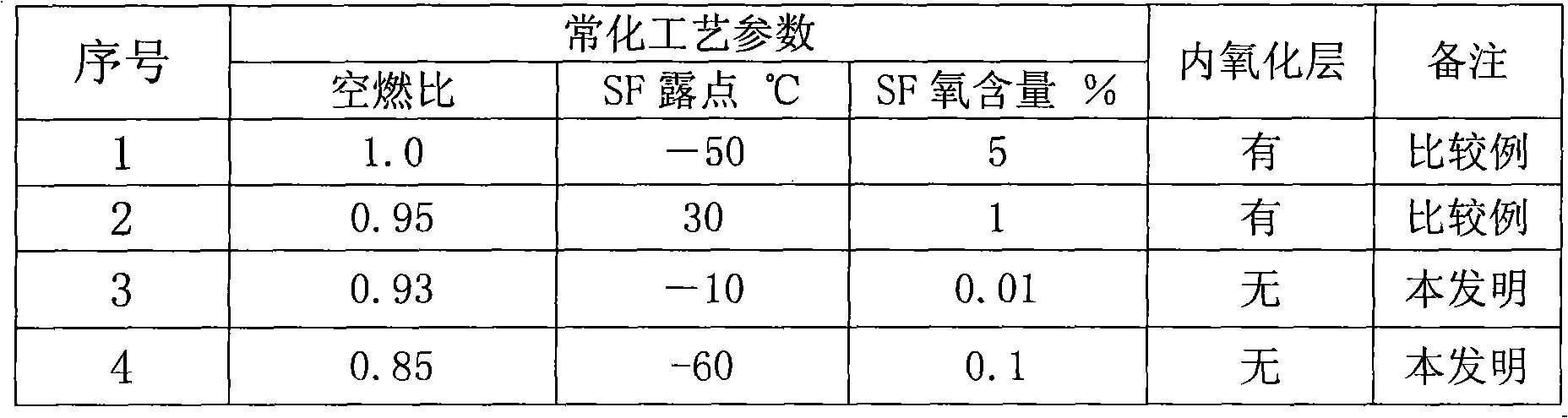

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a treatment method of hot-rolled steel plates, in particular a method for preventing an internal oxidation layer from generating in the non-oriented normalization treatment of electrical hot-rolled strip steel. The normalization treatment comprises a preheating section, a non-oxidation heating section, an even heating section and a cooling section, wherein the non-oxidation heating section adopts direct fire heating and has an air-fuel ratio coefficient of 0.85-0.95. An even heating furnace adopts electric heating or radiation tub heating in the atmosphere of N2 under the condition that in-furnace dew point is 65-10 DEG C below zero and oxygen content is not more than 0.1 percent. The invention reduces and eliminates the internal oxidation layer generated during the normalization of a hot-rolled strip steel during controlling the normalization process, radically eliminates furnace roller nodulation generated in final anneal, avoids subsequent furnace roller nodulation cleaning work, improves the efficiency and decreases the cost.

Description

technical field The invention relates to a treatment method of hot-rolled steel plates, in particular to a method for preventing the generation of internal oxide layers in the normalization treatment of hot-rolled strips of non-oriented electrical steel. Background technique Cold-rolled non-oriented electrical steel with high magnetic induction and low iron loss is a hot spot in the development of non-oriented electrical steel in recent years. It is developed to meet the requirements of high efficiency and miniaturization of various types of motors and electronic transformer cores. The usual production methods of this electrical steel include slab hot rolling, normalizing treatment, cold rolling and annealing treatment. Normalization is a commonly used process for cold-rolled non-oriented electrical steel with high magnetic induction and low iron loss. The purpose is to obtain a coarse grain structure of the hot-rolled sheet before cold-rolling, and to obtain a high-strength...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21D8/02C21D9/52

Inventor 王波苏红星汪志坚王子涛

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com