Ceramic-intermetallic compound composite material containing binder and preparation method thereof

A technology of intermetallic compounds and composite materials, which is applied in the field of in-situ ceramic reinforced intermetallic compound composite materials and its preparation, can solve the problems of less research on composite materials, and achieve the effect of good bonding and clean interface

Inactive Publication Date: 2010-08-25

JILIN UNIV

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, although there are many studies on effective alloying and compounding to solve material brittleness, there are relatively few studies on in-situ ceramic-reinforced intermetallic compound composites using metal as a binder.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

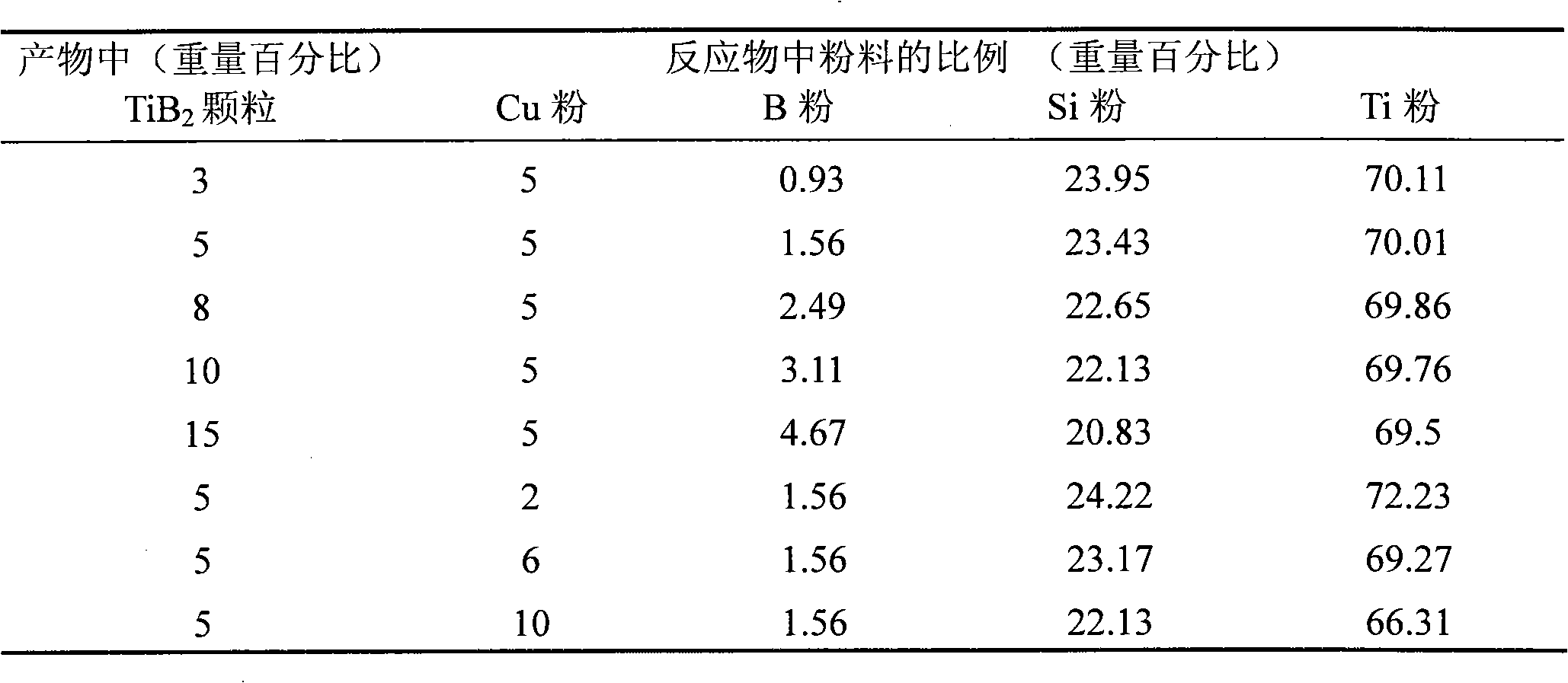

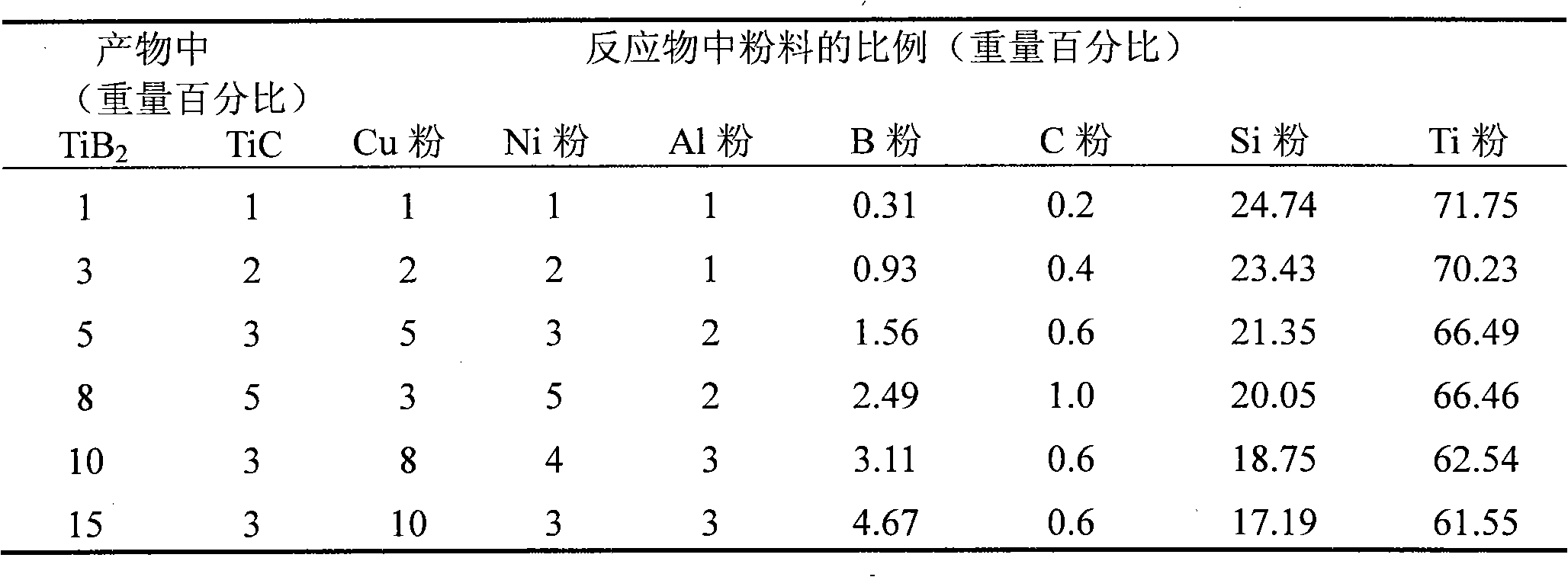

The invention relates to a ceramic-intermetallic compound composite material containing a binder and a preparation method for . The metal binder accounts for less than 20% of the total weight by weight percentage, and ceramic particles in situ are one kind of or two kinds of TiB2 and TiC. The weight percentage of the total weight of the ceramic particles in situ is less than 20%, and the weight percentage of the total weight of the TiB2 and TiC is less than 40%. The preparation method comprises the steps of: (1) mixing Cu, Ni, Fe, Al, Cr, B, C, Si and Ti powder as reactants according to a certain proportion and pressing into a blank; (2) heating the pressed blank in argon atmosphere by resistance wires for preheating, and then heating by the heat of the resistance until combustion synthetic reaction occurs; and (3) pressurizing after reaction to densify the blank, and form in situ ceramic reinforced intermetallic compound the composite material for containing the metal binder. The composite material has the advantages of excellent performance such as high intensity, high rigidity, and the like, simple preparation process, simple equipment, low energy consumption and easy popularization and application.

Description

technical field The invention relates to the field of composite materials, in particular to an in-situ ceramic reinforced intermetallic compound composite material added with a metal binder and a preparation method thereof. Background technique Refractory Ti 5 Si 3 It is a high-temperature intermetallic compound that has attracted much attention because of its good thermodynamic stability, good high-temperature strength and creep resistance, and excellent high-temperature oxidation resistance and corrosion resistance. However, hindering Ti 5 Si 3 The biggest problem in application lies in its extremely low room temperature brittleness and fracture toughness. The research of many scientific and technological workers has found that alloying and compounding are the solution to the problem of Ti 5 Si 3 An effective approach to brittle problems. At present, although there are many studies on effective alloying and compounding in order to solve the brittleness of materials,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C29/18C22C1/05

Inventor 王慧远姜启川吕思婕邱丰

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com