Elemental chlorine free bleaching method for plant fiber stuff

A plant fiber and elemental chlorine technology is applied in the field of pulp bleaching to achieve the effects of reducing pollution, improving pulp strength and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

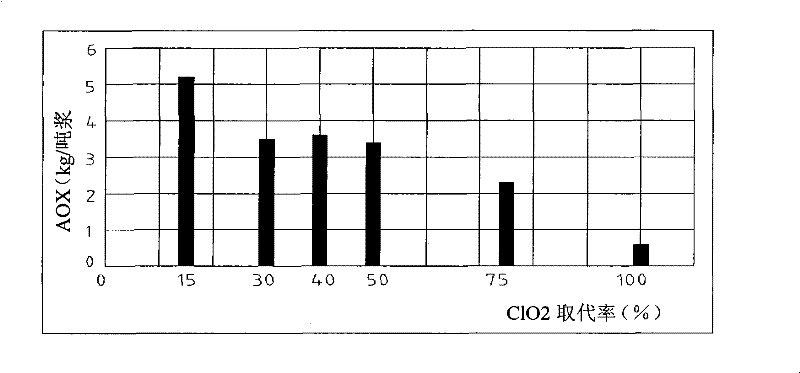

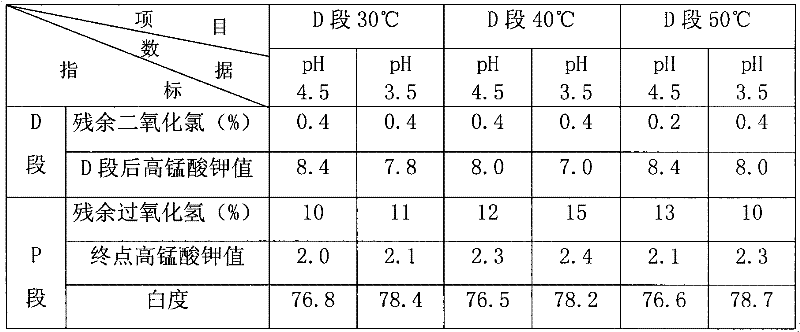

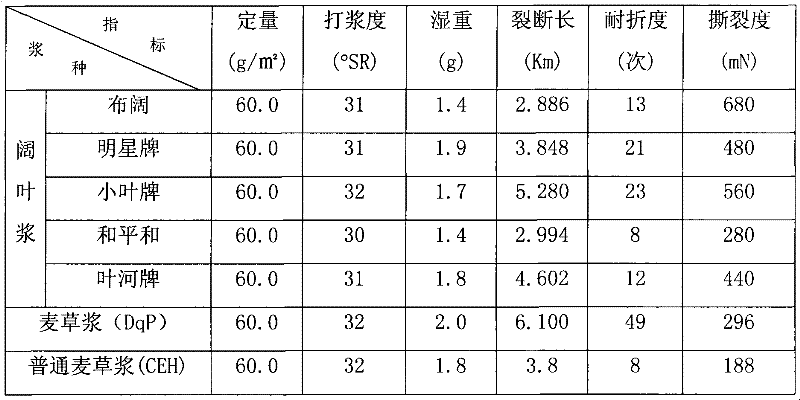

[0041] Wheat straw raw materials are subjected to DqP bleaching after cooking, black liquor extraction, oxygen delignification, screening and purification. Main process conditions of section D: chlorine dioxide dosage 1.0%, end point pH 3.5, slurry concentration 10%, reaction temperature 35°C, reaction time 2h; Q section process conditions: chelating agent dosage 0.15%, pH 3.5, slurry The concentration is 5%, and the reaction time is 10 minutes; the main process conditions of the P section: H 2 o 2 The dosage is 3.0%, the end point pH is 11.5, the slurry concentration is 10%, the reaction temperature is 95°C, and the reaction time is 2h. After the reaction is completed, the pulp is washed to obtain bleached wheat straw pulp. The obtained bleached wheat straw pulp is quantitatively 60g / m 2 , the beating degree is 32°SR, the wet weight is 2.0g, the whiteness is 78.5%ISO, the breaking length is 6.1km, the folding resistance is 49 times, the tearing degree is 296mN, and the AOX...

Embodiment 2

[0043] The rice straw raw material is subjected to DqP bleaching after cooking, black liquor extraction, screening and purification. Main process conditions of section D: chlorine dioxide dosage 1.5%, end point pH 4, slurry concentration 5%, reaction temperature 35°C, reaction time 1.5h; process conditions of section Q: chelating agent dosage 0.2%, pH 5, slurry concentration 5% , the reaction time is 5min; the main process conditions of P section: H 2 o 2 The dosage is 4%, the end point pH is 11, the slurry concentration is 10%, the reaction temperature is 95°C, and the reaction time is 2h. After the reaction is completed, the pulp is washed to obtain bleached straw pulp. Gained bleached rice straw pulp is quantitatively 60g / m 2 , beating degree is 31°SR, wet weight is 1.8g, whiteness is 76.5%ISO, breaking length is 5.6km, folding endurance is 51 times, tearing degree is 280mN, AOX content in wastewater is 0.6-2kg / ton pulp.

Embodiment 3

[0045] Cotton stalk raw materials are subjected to DqP bleaching after cooking, black liquor extraction, screening and purification. Main process conditions of section D: dosage of chlorine dioxide 1.25%, end point pH 4, slurry concentration 5%, reaction temperature 40°C, reaction time 1.0h; process conditions of section Q: chelating agent dosage 0.2%, pH 4, slurry concentration 5% , the reaction time is 8min; the main process conditions of P section: H 2 o 2 The dosage is 4.5%, the end point pH is 11, the slurry concentration is 10%, the reaction temperature is 95°C, and the reaction time is 2h. After the reaction is completed, the slurry is washed to obtain bleached cotton stalk pulp. Gained bleached cotton stalk pulp quantitatively is 60g / m 2 , beating degree is 30°SR, wet weight is 2.1g, whiteness is 79.1%ISO, breaking length is 6.0km, folding endurance is 53 times, tearing degree is 302mN, AOX content in wastewater is 0.6-2kg / ton pulp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com