Rubbish regeneration environment-friendly brick and production method thereof

An environmentally friendly brick and garbage technology, applied in the direction of building materials, etc., can solve the problems of inability to completely dispose of garbage, environmental pollution, energy consumption, etc., and achieve the effects of easy operation, good environmental protection, and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

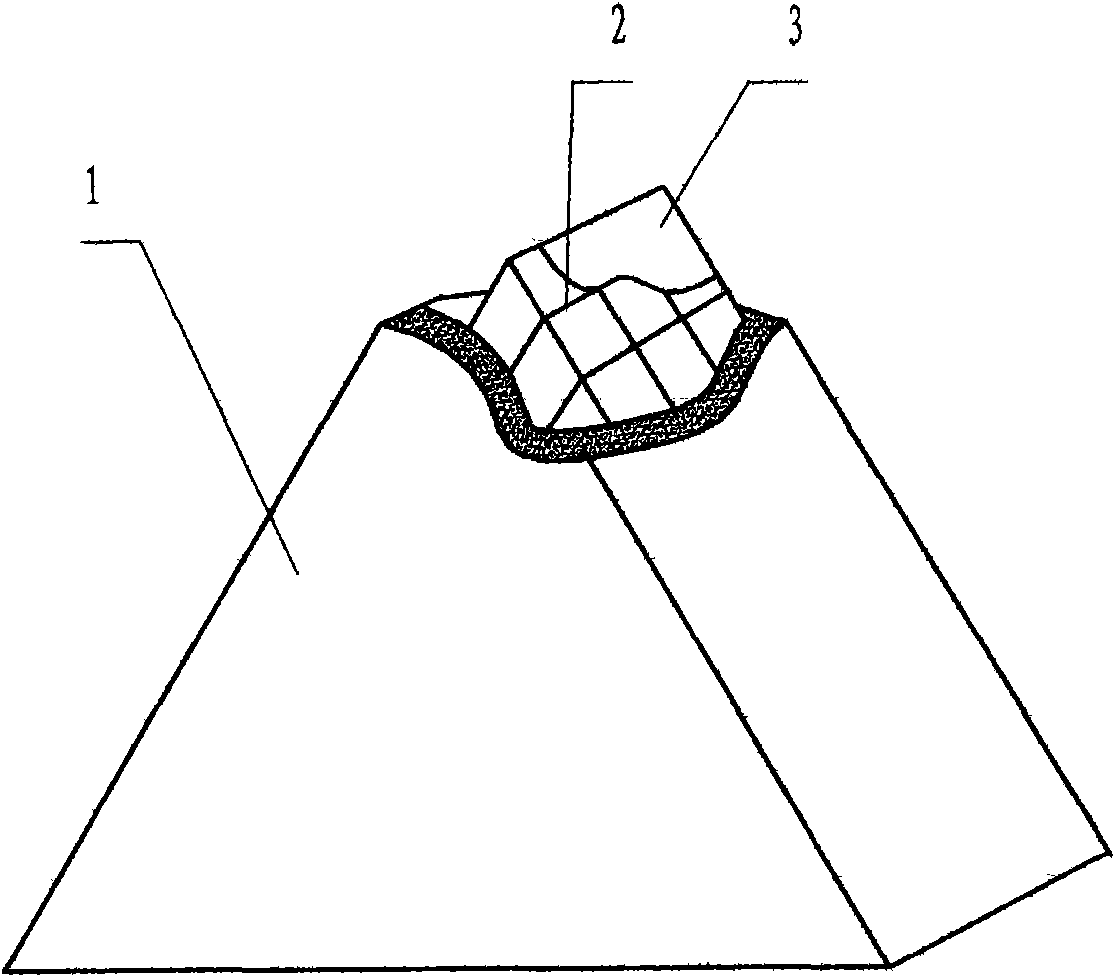

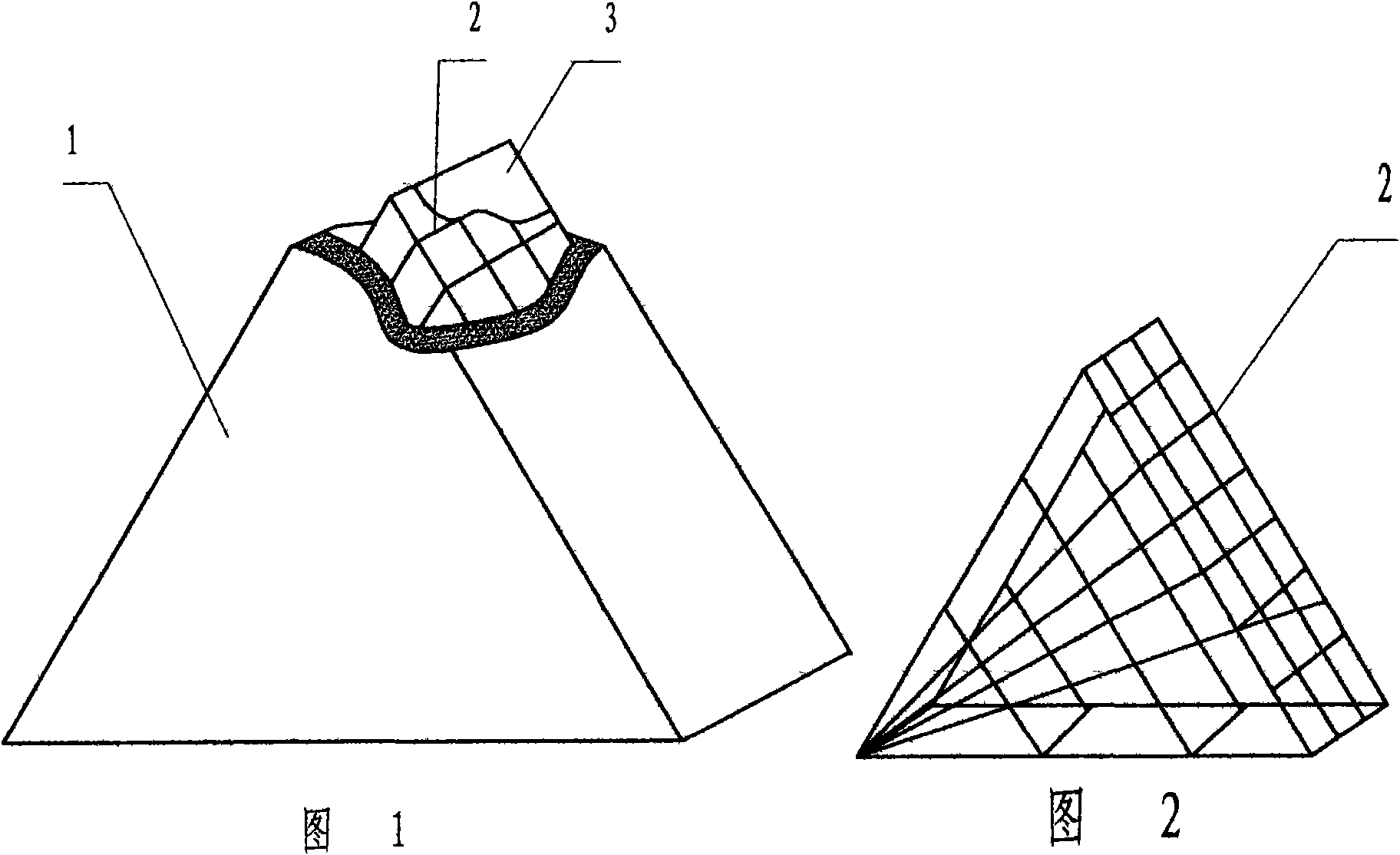

[0021] The present invention will be further described below in conjunction with accompanying drawing and embodiment: embodiment, referring to accompanying drawing,

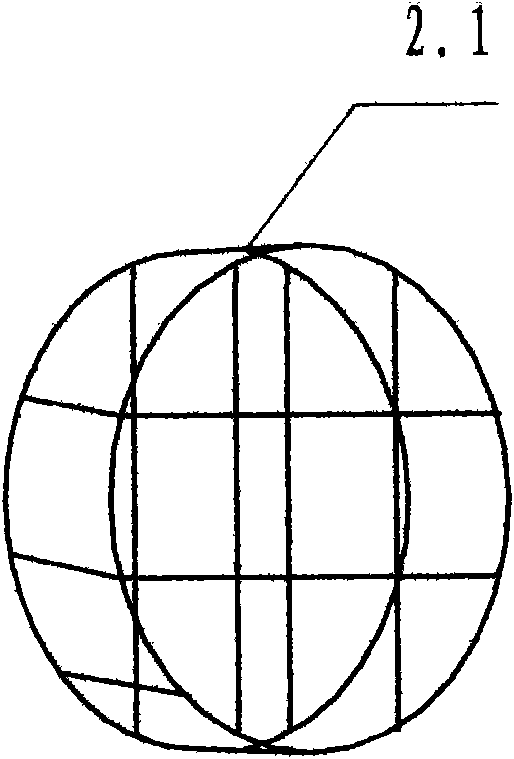

[0022] Garbage recycled environmental protection bricks are composed of garbage compression block 3, steel frame 2, and solid shell 1. The garbage compression block is a block formed by garbage compression, and its outer surface is vacuum-tightly covered with a high-density film. The blocks are placed within said steel skeleton, over which a solid shell is cast. The shapes of the rubbish compression block, the reinforced skeleton and the solid shell are triangle 2, square 2.2, rectangle 2.3, circle 2.1, and polygon; in this embodiment, it is triangle.

[0023] The manufacturing method of garbage recycled environmental protection brick is characterized in that it comprises the following steps:

[0024] 1) collect and process garbage; collect garbage, what collect in the present embodiment is house refuse and cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com