Anticorrosion device for inner cylinder of steel chimney

A technology of anti-corrosion device and steel inner cylinder, which is applied in the direction of building type, covering/lining, building, etc., to achieve the effect of preventing shaking and preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

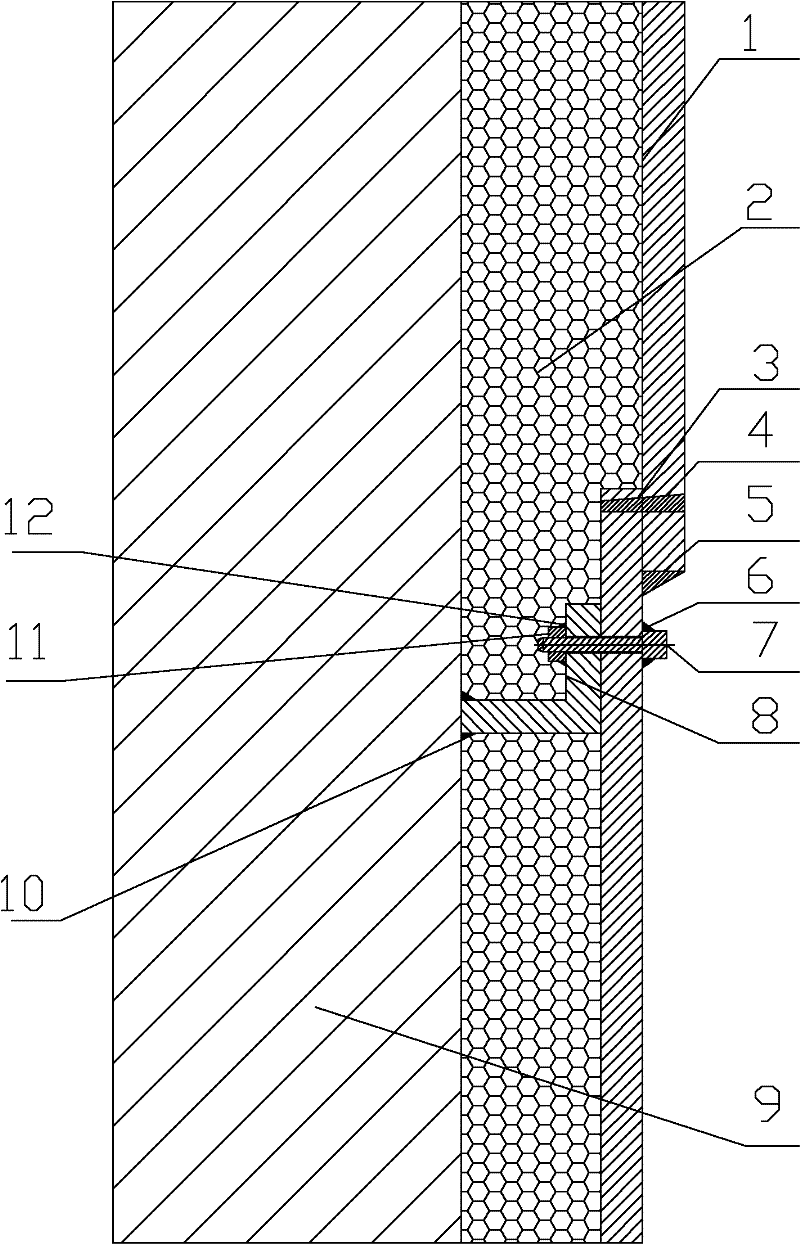

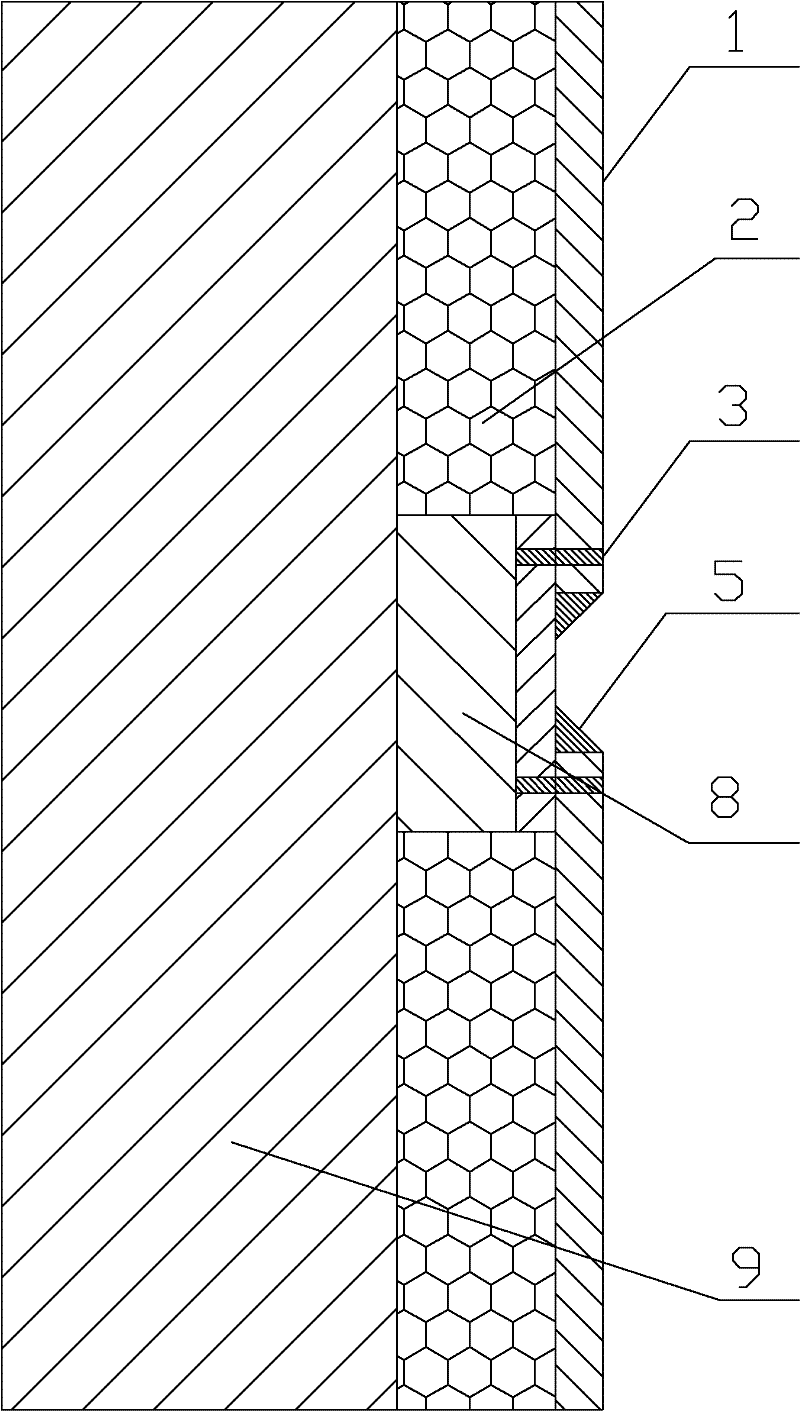

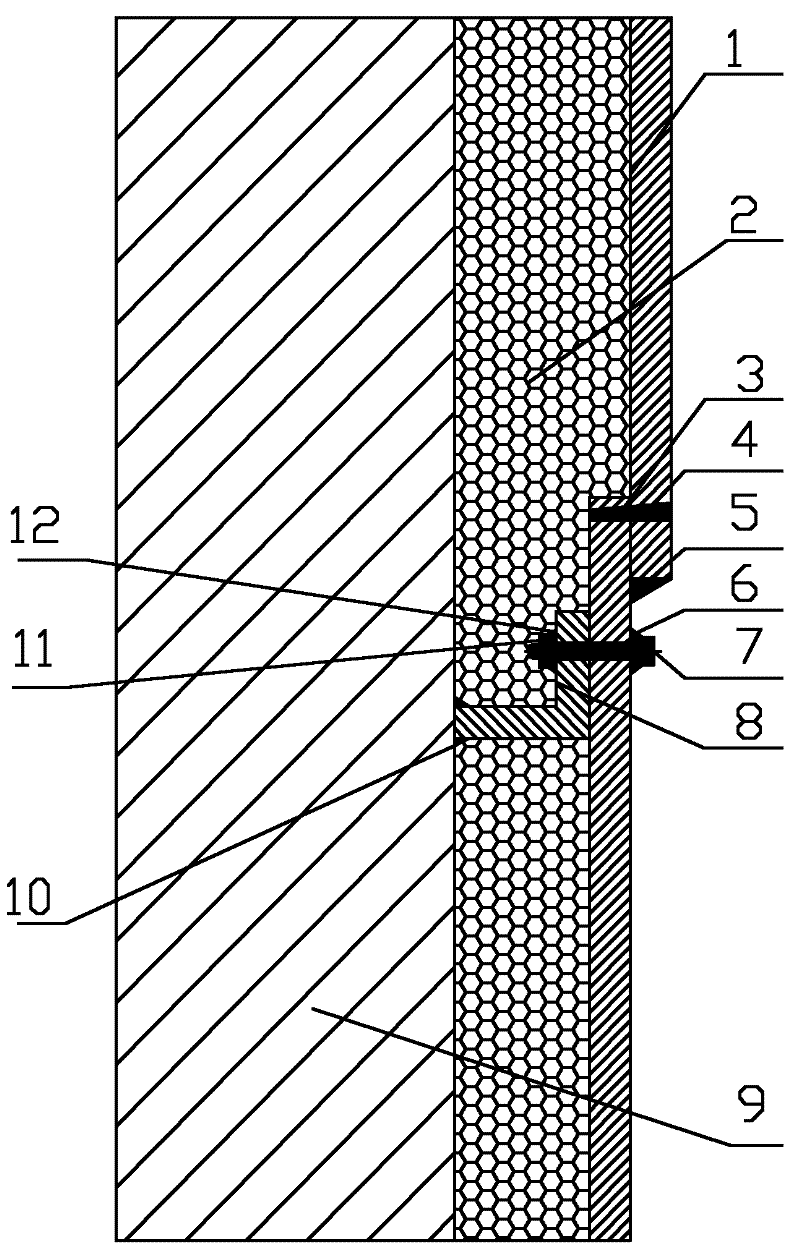

[0016] For the specific technical scheme of the steel chimney inner tube anticorrosion device described in the present invention, refer to figure 2 :

[0017] First, derust the cylindrical surface of the steel inner cylinder, draw lines along the circumference of the inner wall of the chimney at an interval of 1200mm, and use an electric grinder to polish the drawn lines, with the drawn lines as the center, and the grinding width is not less than 100mm.

[0018] Secondly, weld the keel, find the horizontal reference line on the circumference of the ash accumulation platform, weld the first circle of keel along the horizontal reference line, and weld the entire circle of keel from bottom to top at intervals of 1200mm until all steel inner cylinders are evenly welded The upper keel, the carbon steel surface layer of the composite keel is welded with the steel inner cylinder.

[0019] Third, fill with SL200 high-temperature acid-resistant foam board, and fill SL200 high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com