Quartz tuning fork strengthened photoacoustic spectroscopy gas sensor based on acoustic resonator

A technology of quartz tuning fork and photoacoustic spectroscopy, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of increasing the manufacturing cost and using cost of the device, making the acoustic resonance condition not fully satisfied, reducing the effect of resonance enhancement, etc., and reducing the manufacturing cost. And the cost of use and maintenance, the effect of improvement, and the effect of eliminating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

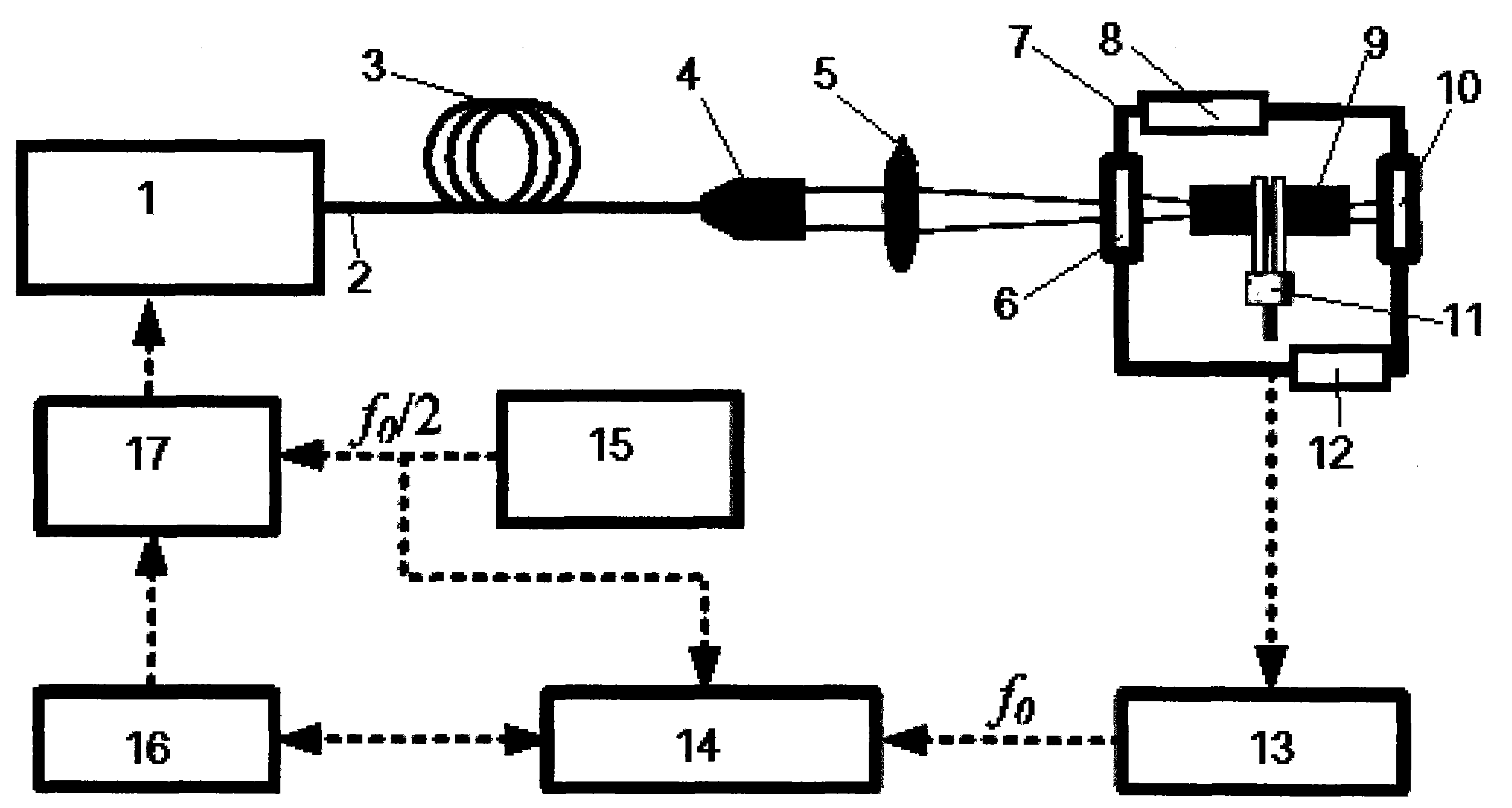

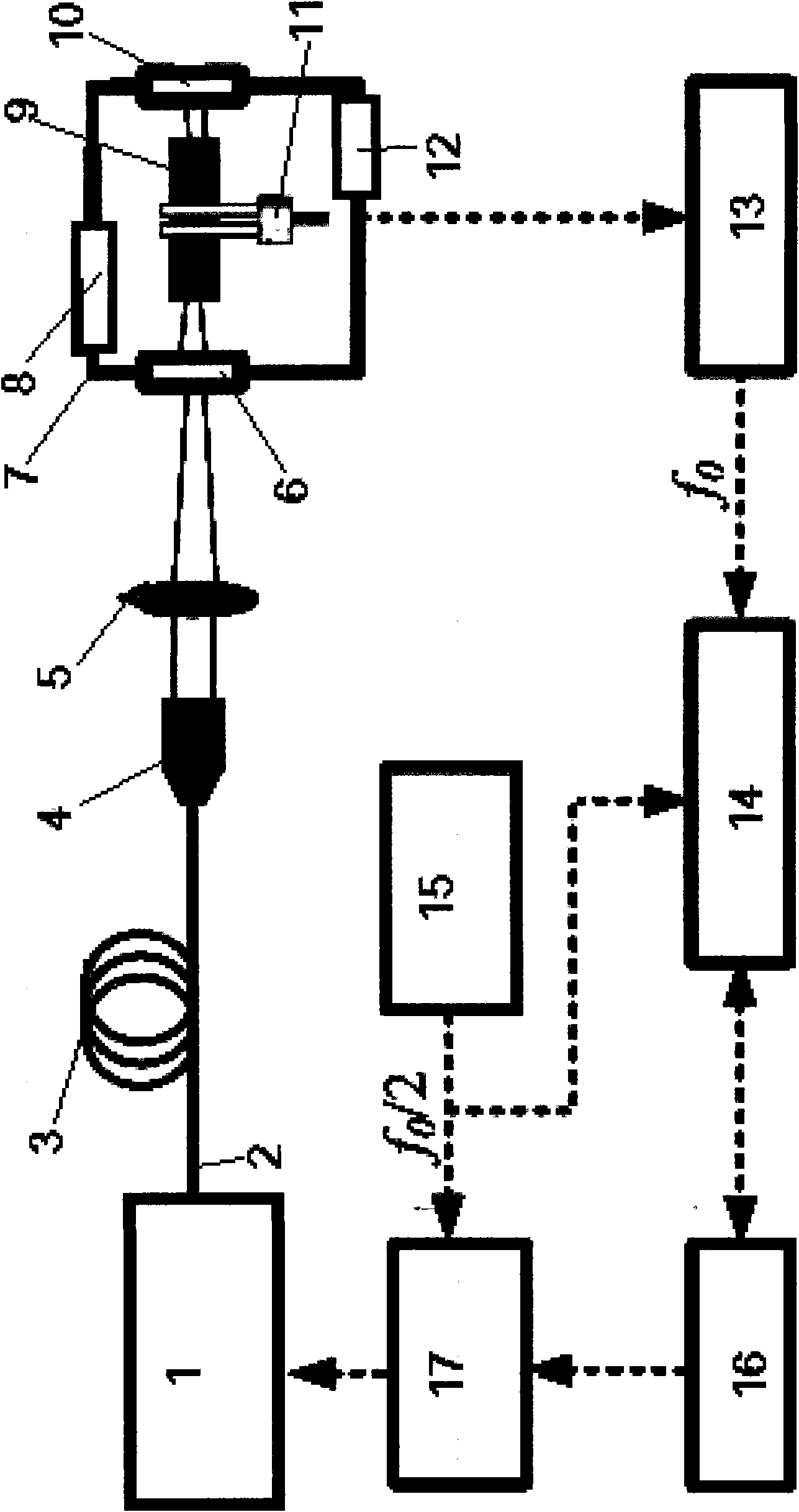

[0016] Referring to Figure 1, Figure 2, Figure 3 and Figure 4, the optical path 2 of the laser 1 is provided with an optical fiber 3, a collimating lens 4, a focusing lens 5 and an incident window 6 of a sample cell 7, as well as an acoustic resonator 9 and a sample cell. 7 of the exit window 10. among them,

[0017] The upper and lower sides of the sample cell 7 are respectively provided with an air inlet 8 and an air outlet 12.

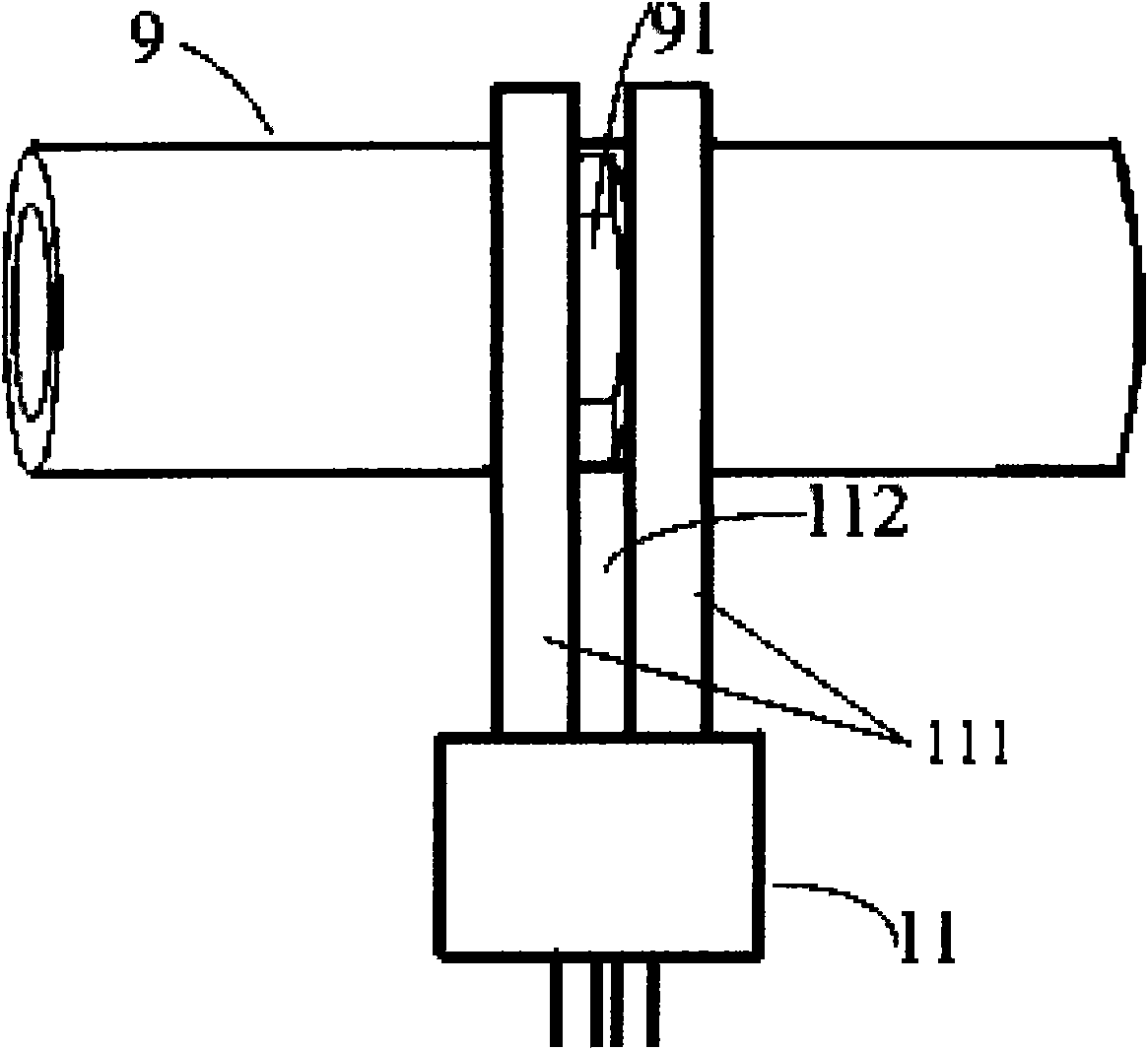

[0018] The acoustic resonant cavity 9 is a tube with a length of 8 mm, an outer diameter of 0.7 mm, and an inner diameter of 0.45 mm, and a slit 91 with a width of 0.15 mm and a length of 0.45 mm is placed in the middle. The slit 91 is perpendicular to the tube length of the acoustic cavity 9, the tube axis of the acoustic cavity 9 is coaxial with the optical path 2, and the focus of the focusing lens 5 is located at the slit 91 in the acoustic cavity 9.

[0019] The slit 91 handles the tuning fork arm 111 of the quartz tuning fork 11, and the distance b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com