Preparation method of fully compact massive anisotropic nanocrystalline PrCo5 magnet

An anisotropic, nanocrystalline technology, applied in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., to achieve the effects of low cost, simple preparation process and good magnetic properties

Inactive Publication Date: 2010-08-25

BEIJING UNIV OF TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But nanocrystalline PrCo 5 The powder is isotropic, so its remanence is only half of the saturation magnetization

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

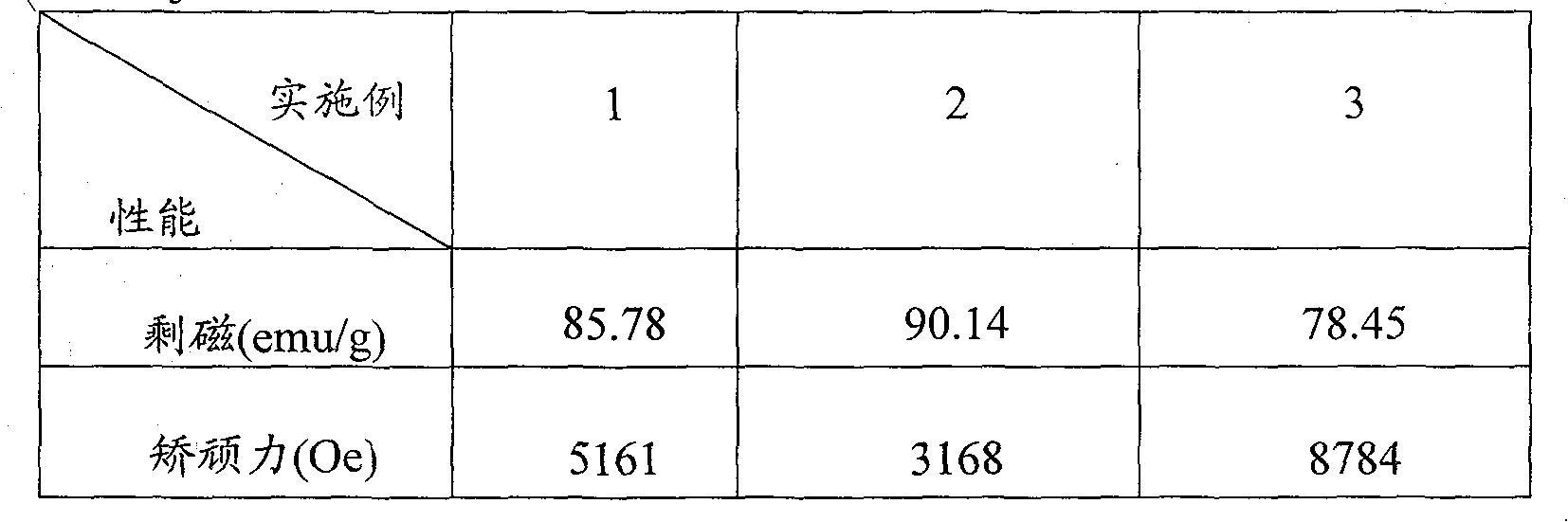

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a preparation method of a fully compact massive anisotropic nanocrystalline PrCo5 magnet, belonging to the field of preparation of magnetic materials. The traditional powder metallurgical method for preparing a PrCo5 permanent magnet alloy has the problems of complex process, low coercive force, poor mechanical properties and corrosion resistance of the alloy, and the like. In the invention, the method comprises the following steps: smelting Pr and Co in a vacuum shower furnace according to the component proportion of the PrCo5; carrying out ball milling in a ball mill at the rotation speed greater than 400prm for more than 6h to obtain amorphous powder; and then filling the amorphous powder in a sintered carbide mould; and carrying out quick hot pressing and hot deformation treatment by a discharge plasma sintering technology to prepare the fully compact massive anisotropic PrCo5 nanocrystalline permanent magnet alloy. The method of the invention has simple process, short production cycle and low cost, and the prepared magnet has high compactness, fine crystalline grains, good C-axis crystalline texture and high magnetic performance.

Description

technical field The invention belongs to the field of magnetic material preparation, in particular to a fully dense block anisotropic nanocrystalline PrCo 5 Preparation method of permanent magnetic material. Background technique SmCo 5 Permanent magnet alloys have excellent intrinsic magnetism and good high-temperature characteristics, and are widely used in environments with high temperature requirements. with SmCo 5 Compared with permanent magnet alloy, it also has CaCu 5 Structure of PrCo 5 The permanent magnet alloy has a higher room temperature saturation magnetization, and its theoretical maximum energy product can reach 39MGOe, so it has become a research hotspot in the field of high-temperature magnets. At present, the traditional powder metallurgy method is generally used in the industry to prepare PrCo 5 permanent magnet alloy. PrCo prepared by this method 5 The grain size of the permanent magnet alloy is micron scale, so the coercive force of the alloy is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01F1/055H01F41/02

Inventor 刘卫强岳明吕文春张东涛张久兴

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com