Preparation method of thin film transistor based on induced longitudinal crystallization polycrystalline silicon

A polysilicon thin film and thin film transistor technology, which is applied in the manufacture of semiconductor/solid state devices, electrical components, circuits, etc., can solve the problems of unstable performance of polysilicon thin films and high leakage current, so as to reduce current and gate-induced drain leakage current, The effect of reducing the residual concentration

Inactive Publication Date: 2010-08-25

GUANGDONG SINODISPLAY TECH

View PDF2 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

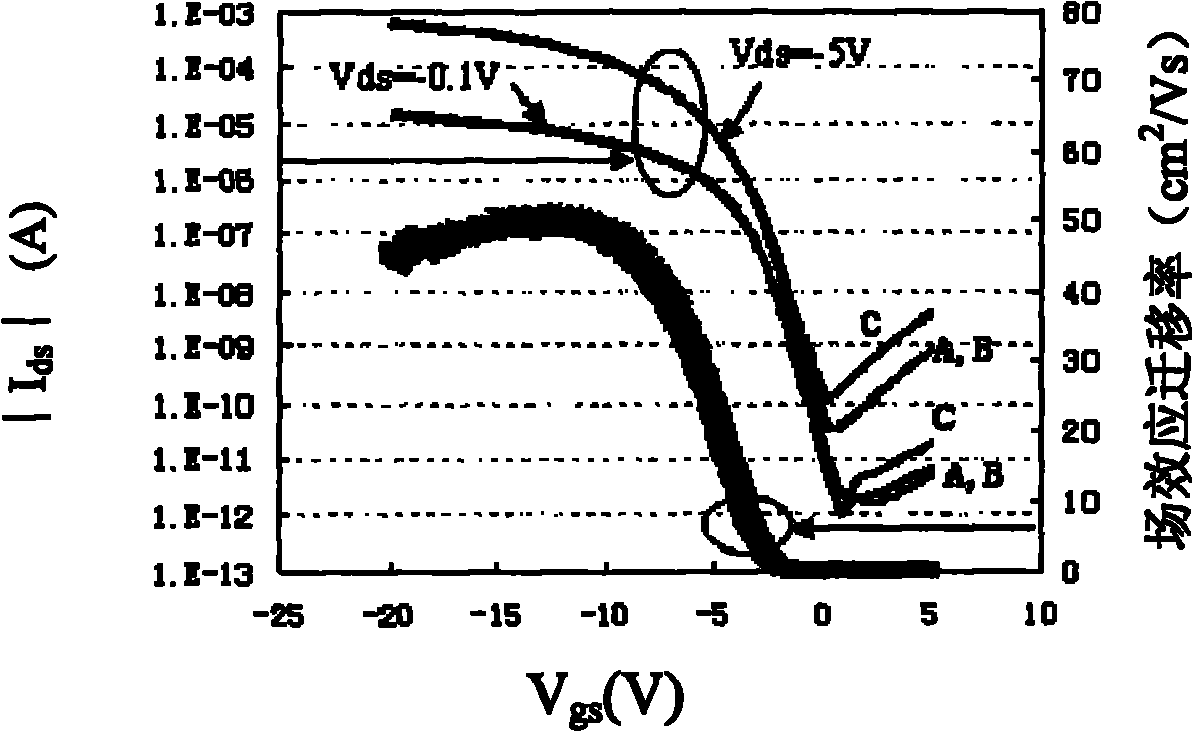

When the MILC method is used, the pure metal nickel deposited by evaporation is usually used as the induced film material, but the obtained polysilicon film contains more nickel residues, and the ratio of nickel / silicon is about 10 -3 The order of magnitude (IEEE Trans, Electron Devices, 48 (1655), 2001), this higher nickel residual concentration easily causes the unstable performance of the polysilicon thin film prepared, so that the off-state current (I off ) and gate-induced leakage current (GIDL) are higher

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a preparation method of a thin film transistor based on an induced longitudinal crystallization polycrystalline silicon film, which comprises the steps of: forming a noncrystalline silicon layer on a substate and forming an oxide layer; etching a groove on the oxide layer to expose the noncrystalline silicon layer; forming a nisiloy oxide film with thickness of 100nm on the exposed noncrystalline silicon layer and annealing for 1h at a temperature of 590 DEG C under an inert or protective gas environment; after finishing crystallization, removing residual nisiloy oxide and the oxide layer and forming an active island through photoetching; depositing 100nm of oxide layer; irradiating the surface of a sample by adopting pulse laser; finally, forming a source leakage electrode after ions are injected by using a grid insulation layer as the 100nm oxide layer and 280nm polycrystalline silicon as a grid electrode; and depositing a 500nm oxide layer to form a contact hole and a metal leading-out electrode. By adopting the method, close state current of the TFT and leakage current of a grid initiation leakage electrode are lowered.

Description

technical field The invention belongs to the field of thin film transistor preparation, in particular to a preparation method of a thin film transistor based on a laterally induced crystallization low temperature polysilicon thin film. Background technique Although most active-matrix liquid crystal displays (AM-LCDs) are still mostly composed of amorphous silicon (a-Si) thin-film transistors (TFTs), for active-matrix displays, polysilicon (p-Si) thin-film transistors can be used. Provides higher resolution and smaller pixels, and when using polysilicon TFTs, some driver circuits can also be integrated on the glass substrate. In addition, polysilicon TFTs are more stable than amorphous silicon TFTs in driving organic light-emitting diode displays (OLEDs), so low-cost, high-performance and more reliable low-temperature polysilicon (LTPS) processing techniques are required. Existing methods for obtaining polycrystalline silicon thin films mainly include solid state crystalliz...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L21/336H01L21/20

Inventor 赵淑云

Owner GUANGDONG SINODISPLAY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com