Multi-junction solar cell with high peak current density tunnel junction

A multi-junction solar cell and current density technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of uneven doping concentration, high cost, and limited application of multi-junction III-V material compound solar cells, etc. Achieve the effect of steep interface and high doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

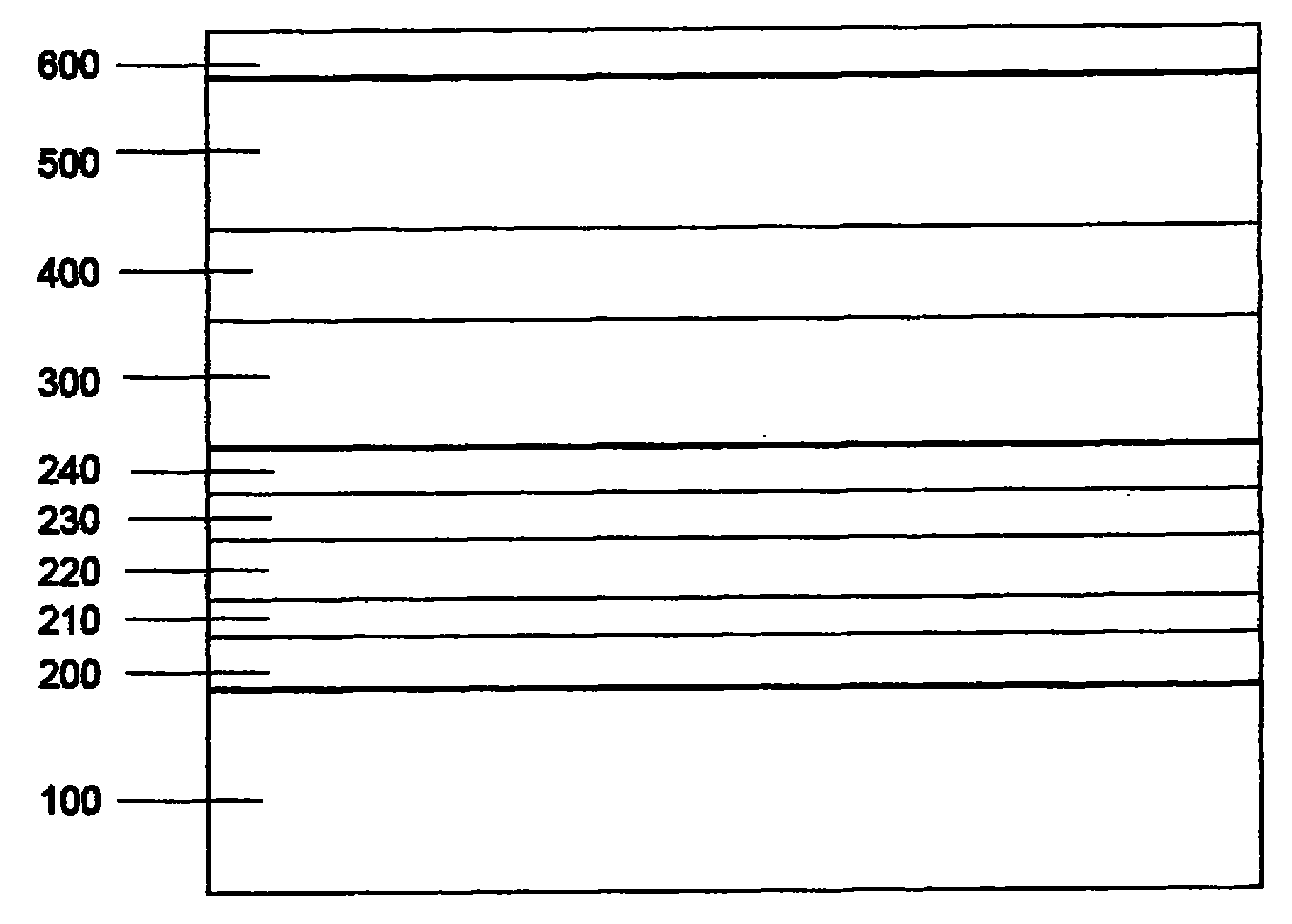

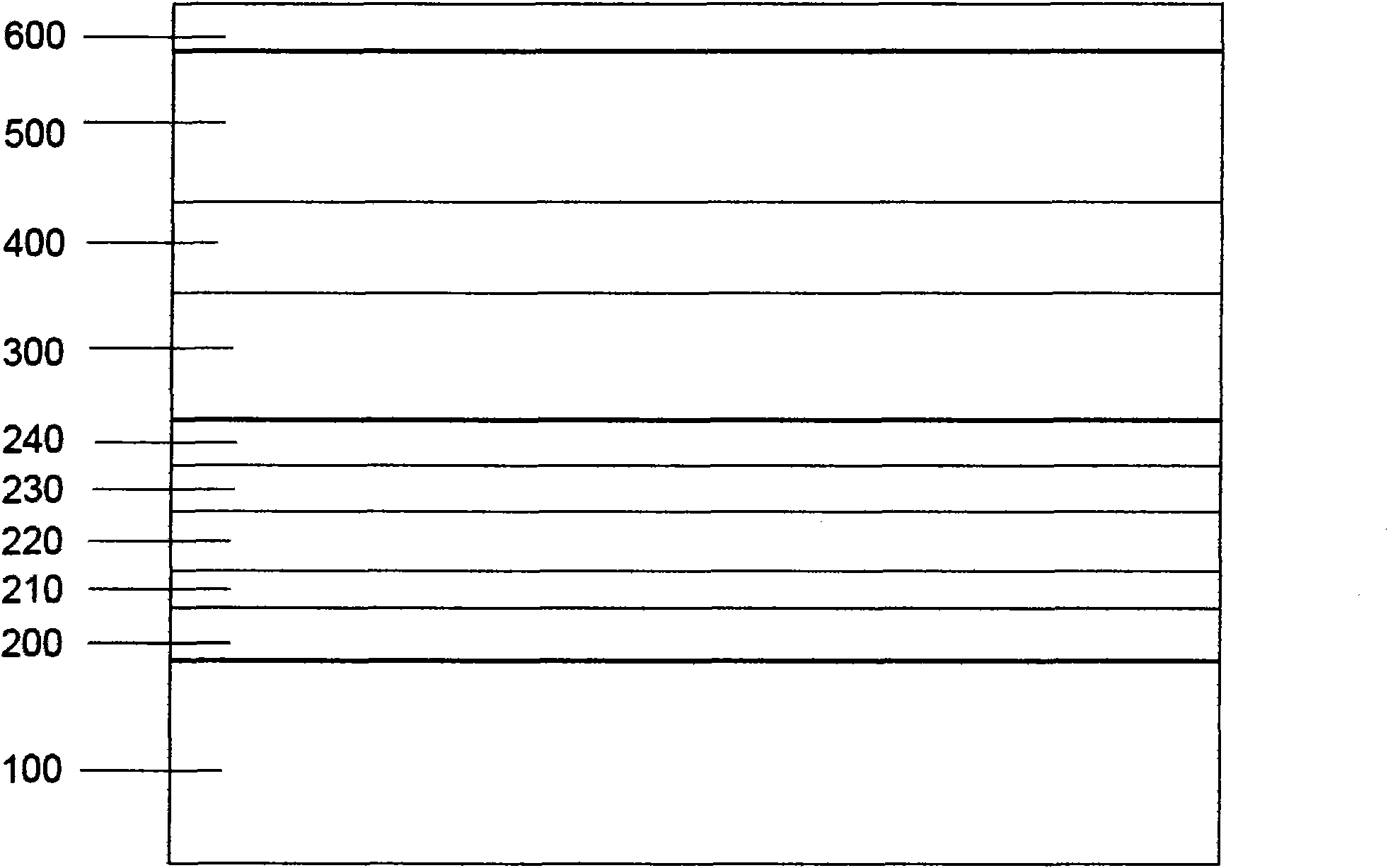

[0030] As shown in Figure 1, a multi-junction solar cell with a high peak current density tunnel junction, the tunnel junction connecting the Ge bottom cell 100, the GaInAs middle cell 300 and the GaInP top cell 500 has five layers, and the first layer is anti-diffusion The first layer is an n-type GaInP film 200; the second layer is a GaAs film 210 co-doped with Si and Te; the third layer is a Te-doped GaAs film 220; the fourth layer is a C-doped AlGaAs film 230; the fifth layer is an anti- The diffusion layer is a p-type AlGaInP thin film 240 .

[0031] The above-mentioned multi-junction solar cell with high peak current density tunneling junction, its preparation steps are as follows:

[0032] In the MOCVD system, the first Ge bottom cell 100 is grown.

[0033] Grow a layer of n-type anti-diffusion layer GaInP film 200, the growth temperature is 65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com