Manufacturing process of airbag type vibration isolating pad

A manufacturing process and anti-vibration pad technology, which is applied in the field of airbag type anti-vibration pad manufacturing technology, and can solve problems such as poor cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

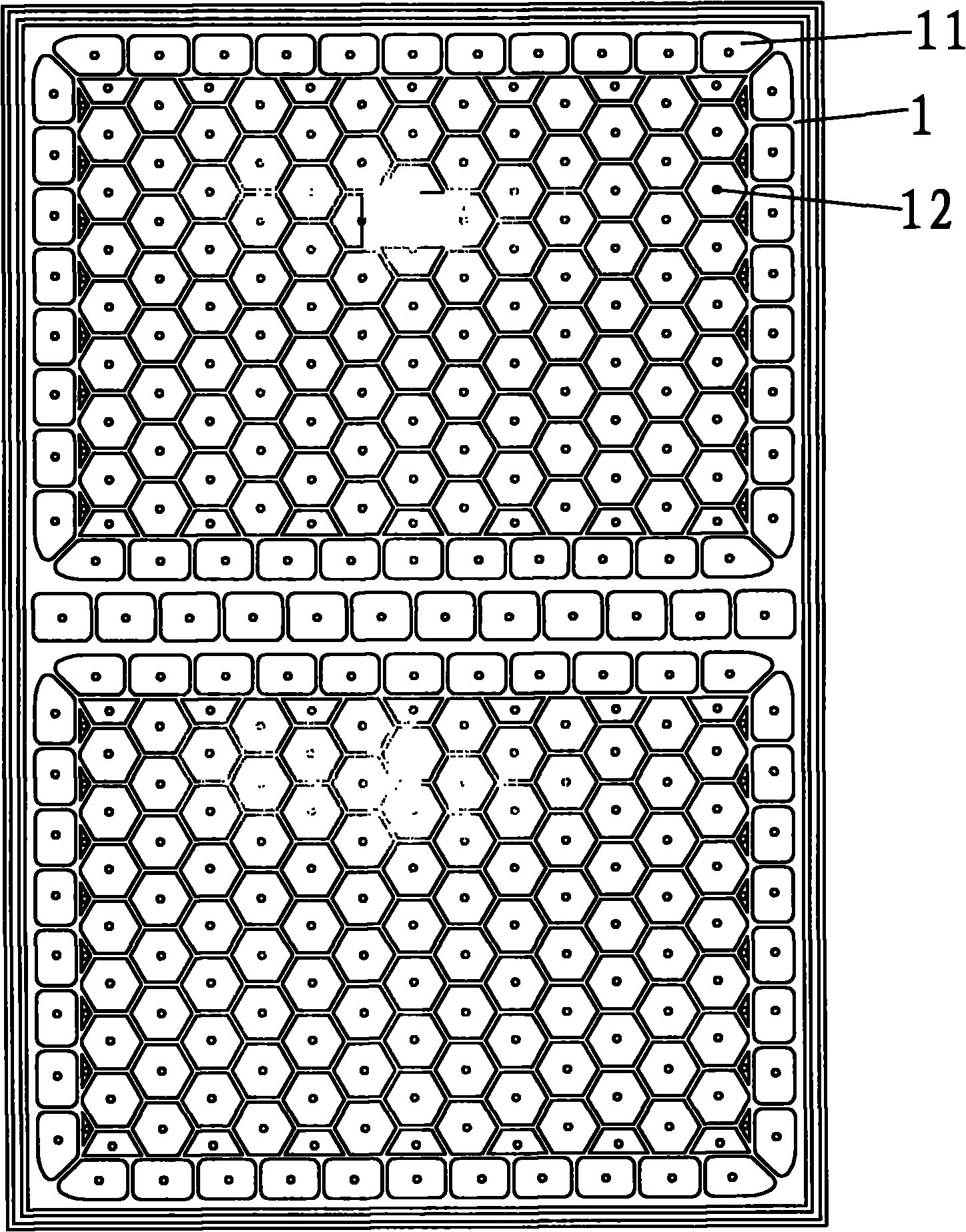

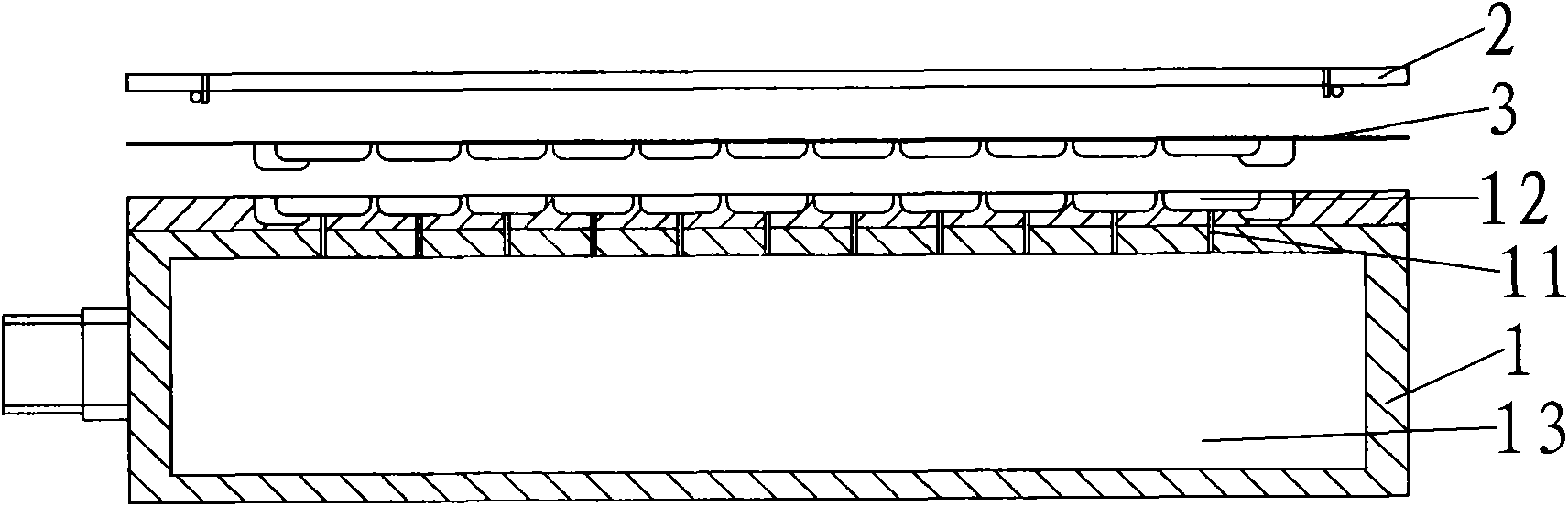

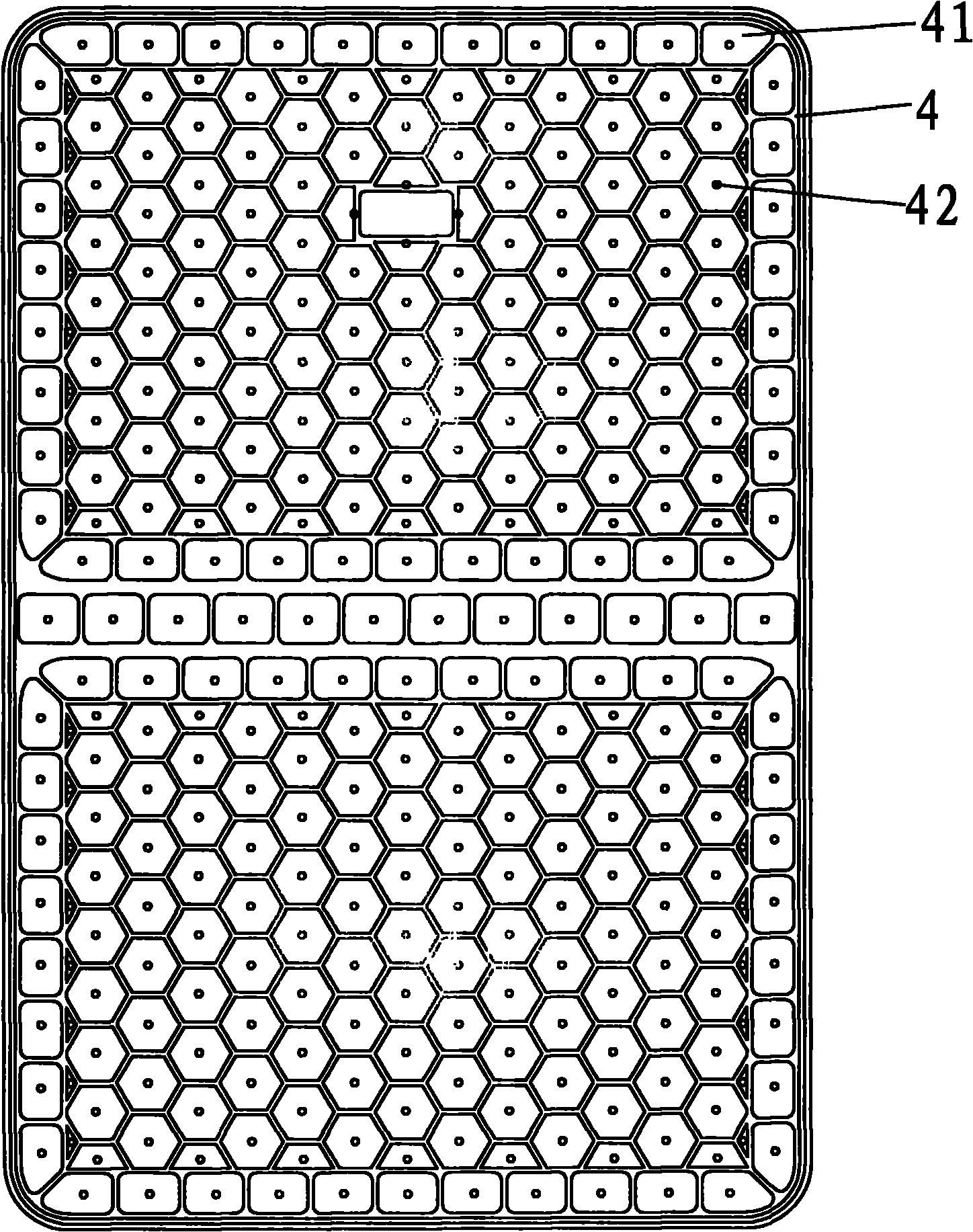

[0015] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the manufacturing process of the airbag type anti-vibration pad is as follows: 1. First bundle the TPU sheet material, widen the four sides by 2cm according to the product specification area, and cut into sheet material; 2. Put the cut sheet material into No. 1 molding die 1; 3. Press platen 2 on the sheet 3, fasten the platen 2; 4. Use a vacuum heating molding machine to make multiple grooves on the sheet, the heating temperature is 400 ° C, positive Negative 10°C, running speed 0.7 m / min, vacuum degree 20kg, hold pressure for 6 seconds; 5. Put the material made of multiple independent grooves into No. 2 mold 4, and then stack a layer of fabric 5 to produce Hollow, pump out the gas in the No. 2 mold to form a negative pressure in the air chamber. According to the pressure requirements of the product on the air bag, adjust the pressure valve, close the high-frequency machine, use 2.1A current, generate high-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com