Method for preparing metanilic acid by catalyzing and hydrogenating 3-nitrobenzenesultonic acid

A technology of nitrobenzenesulfonic acid and aminobenzenesulfonic acid, which is applied in the preparation of sulfonic acid and organic chemistry, can solve the problems of catalyst deactivation, achieve high selectivity, overcome high cost, and simple use and regeneration technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

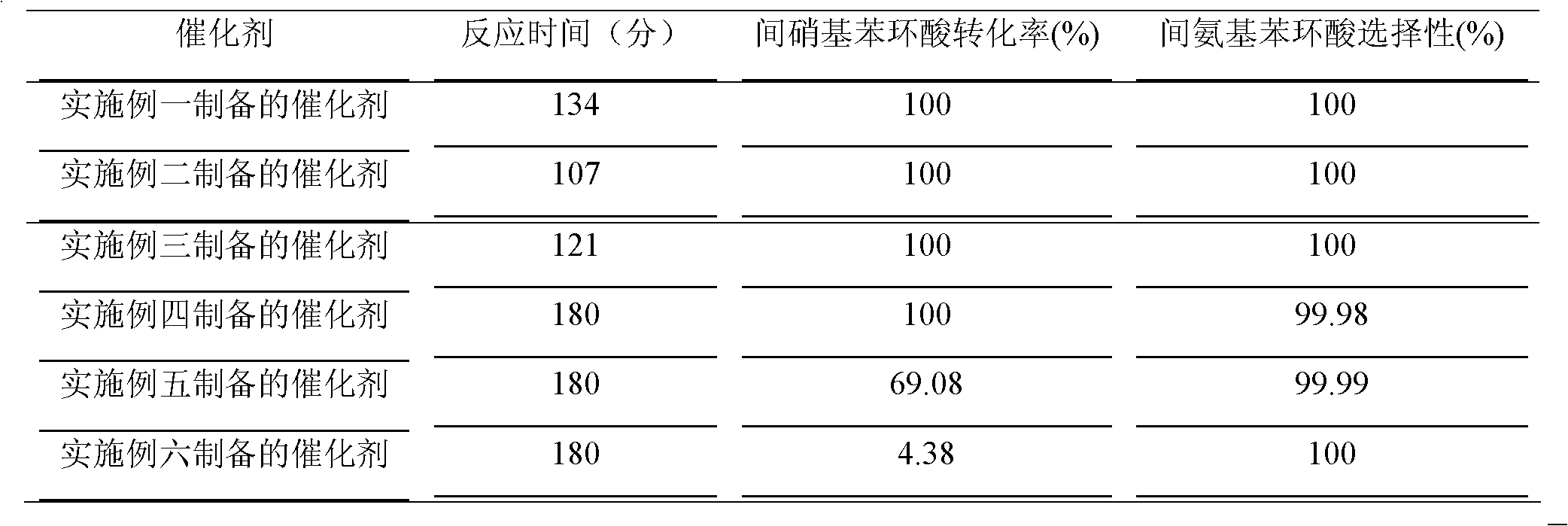

Examples

Embodiment 1

[0022] Weigh 10g coconut shell activated carbon, the specific surface area of activated carbon is 1600m 2 / g, using deionized water to prepare activated carbon into a 100ml slurry at a temperature of 80°C, slowly add 10ml of H 2 PdCl 4 solution (Pd content is 0.05g / ml), stirred for 6h, then adjusted the pH value of the solution to weakly alkaline (pH=8) with 10% NaOH solution, and lowered the temperature to room temperature, filtered, and washed with deionized water to neutral. The unreduced catalyst was prepared into a 150 ml slurry at 30° C. using deionized water, then 2 ml of 85% hydrazine hydrate solution was slowly added dropwise, and stirring was continued for 2 hours. The reduced catalyst was filtered, washed with deionized water until neutral, and finally dried in the air at room temperature, and the wet sample was taken and sealed for storage.

Embodiment 2

[0024] Weigh 10g coconut shell activated carbon, the specific surface area of activated carbon is 1600m 2 / g, use deionized water to prepare activated carbon into 100ml slurry at 80°C, slowly add 20ml of H 2 PdCl 4 solution (Pd content is 0.05g / ml), stirred for 6h, then adjusted the pH value of the solution to weakly alkaline (pH=8) with 10% NaOH solution, and lowered the temperature to room temperature, filtered, and washed with deionized water to neutral. The unreduced catalyst was prepared into a 150 ml slurry at 30° C. using deionized water, then 4 ml of 85% hydrazine hydrate solution was slowly added dropwise, and stirring was continued for 2 hours. The reduced catalyst was filtered, washed with deionized water until neutral, and finally dried in the air at room temperature, and the wet sample was taken and sealed for storage.

Embodiment 3

[0026] Weigh 10g coconut shell activated carbon, the specific surface area of activated carbon is 1600m 2 / g, use deionized water to prepare activated carbon into 100ml slurry at 80°C, slowly add 16ml of H 2 PdCl 4 solution (Pd content is 0.05g / ml), stirred for 6h, then adjusted the pH value of the solution to weakly alkaline (pH=8) with 10% NaOH solution, and lowered the temperature to room temperature, filtered, and washed with deionized water to neutral. The unreduced catalyst was prepared into a 150 ml slurry at 30° C. using deionized water, then 3.5 ml of 85% hydrazine hydrate solution was slowly added dropwise, and stirring was continued for 2 hours. The reduced catalyst was filtered, washed with deionized water until neutral, and finally dried in the air at room temperature, and the wet sample was taken and sealed for storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com