Method for industrially preparing 6-purinethol

A technology of mercaptopurine and hypoxanthine, which is applied in the field of industrial preparation of 6-mercaptopurine, can solve the problems of environmental pollution, high cost, and long process, and achieve the effects of high yield, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

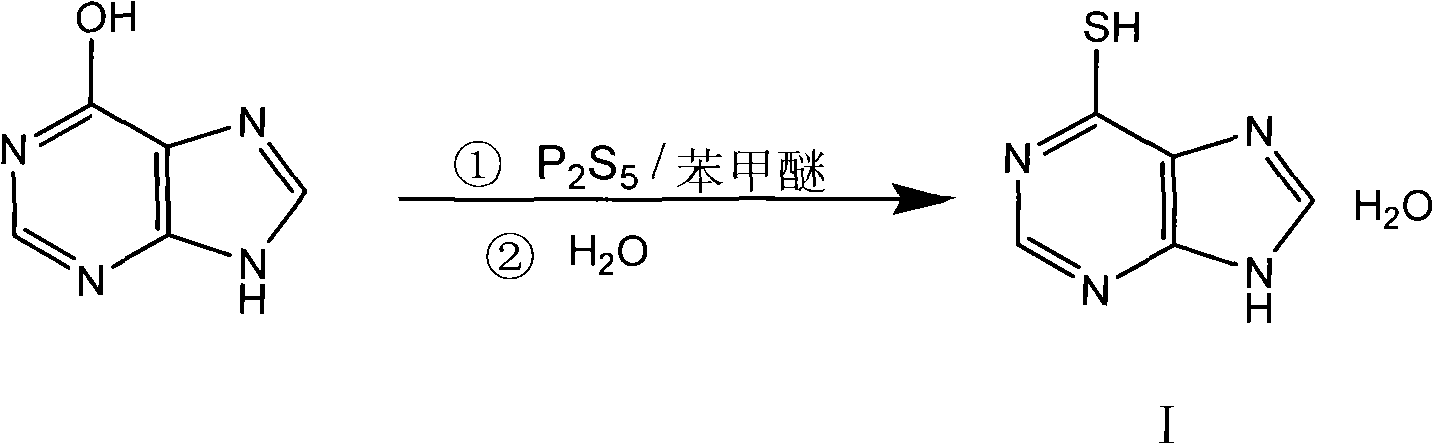

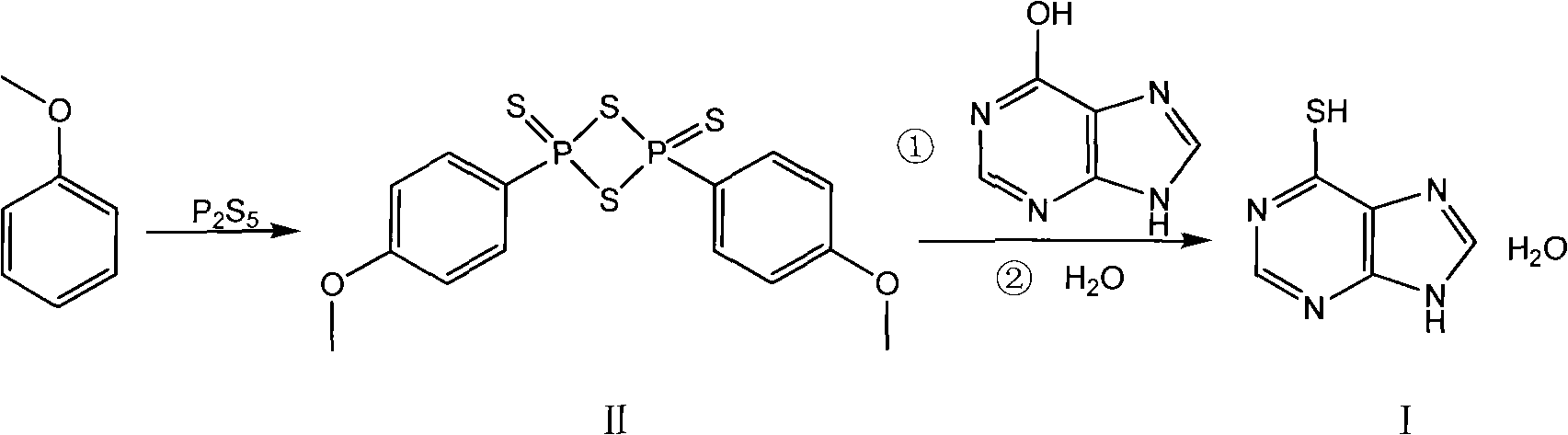

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: One-pot method prepares 6-mercaptopurine

[0024] Weigh 222g of phosphorus pentasulfide and 1080g of anisole, heat to 150°C, add 136g of hypoxanthine after the solids are completely dissolved, and keep at 150°C. TLC (developer: dichloromethane:methanol:ammonia=90:7:3) was used to detect the reaction. When hypoxanthine disappeared, cool to room temperature. Filter and recover the filtrate for application. The solid was recrystallized from water to obtain 155 g of product with a yield of 91.2% and a purity of 98.8%. 1 HNMR (DMSO): δ 8.2 (1H, s); 8.4 (1H, s); 13.8 (1H, s). IR (cm -1 ): 3005, 1615, 1529, 1408, 1346, 1225, 1014, 875.

Embodiment 2

[0025] Embodiment 2: One-pot method prepares 6-mercaptopurine

[0026] Weigh 222g of phosphorus pentasulfide and 1080g of anisole, heat to 150°C, add 136g of hypoxanthine after the solids are completely dissolved, and keep at 150°C. TLC detection reaction, when the hypoxanthine disappears, distill the anisole to dryness, and recover the anisole. After cooling to room temperature, the solid was recrystallized from water. 158g of product was obtained with a yield of 92.9% and a purity of 98.6%.

Embodiment 3

[0027] Embodiment 3: One-pot method prepares 6-mercaptopurine

[0028] 222g of phosphorus pentasulfide, 1080g of anisole and 136g of hypoxanthine were weighed and placed in a container at the same time, heated to 150°C and kept at 150°C. TLC detection reaction, when the hypoxanthine disappeared, cooled to room temperature, filtered, the filtrate was recovered, and the solid was recrystallized with water to obtain 150 g of the product with a yield of 88.2% and a purity of 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com