Device and method for producing environmentally-friendly revived rubber

The technology of a production device and production method is applied in the field of waste rubber recycling processing and utilization technology and its device, which can solve the problems of uneven mixing, uneven quality of desulfurized rubber materials, large fluctuations in quality of rubber powder, and uneven heating of rubber powder, so as to improve the plasticizing process. Speed, save energy and manpower, solve the effect of rubber powder sticking to the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

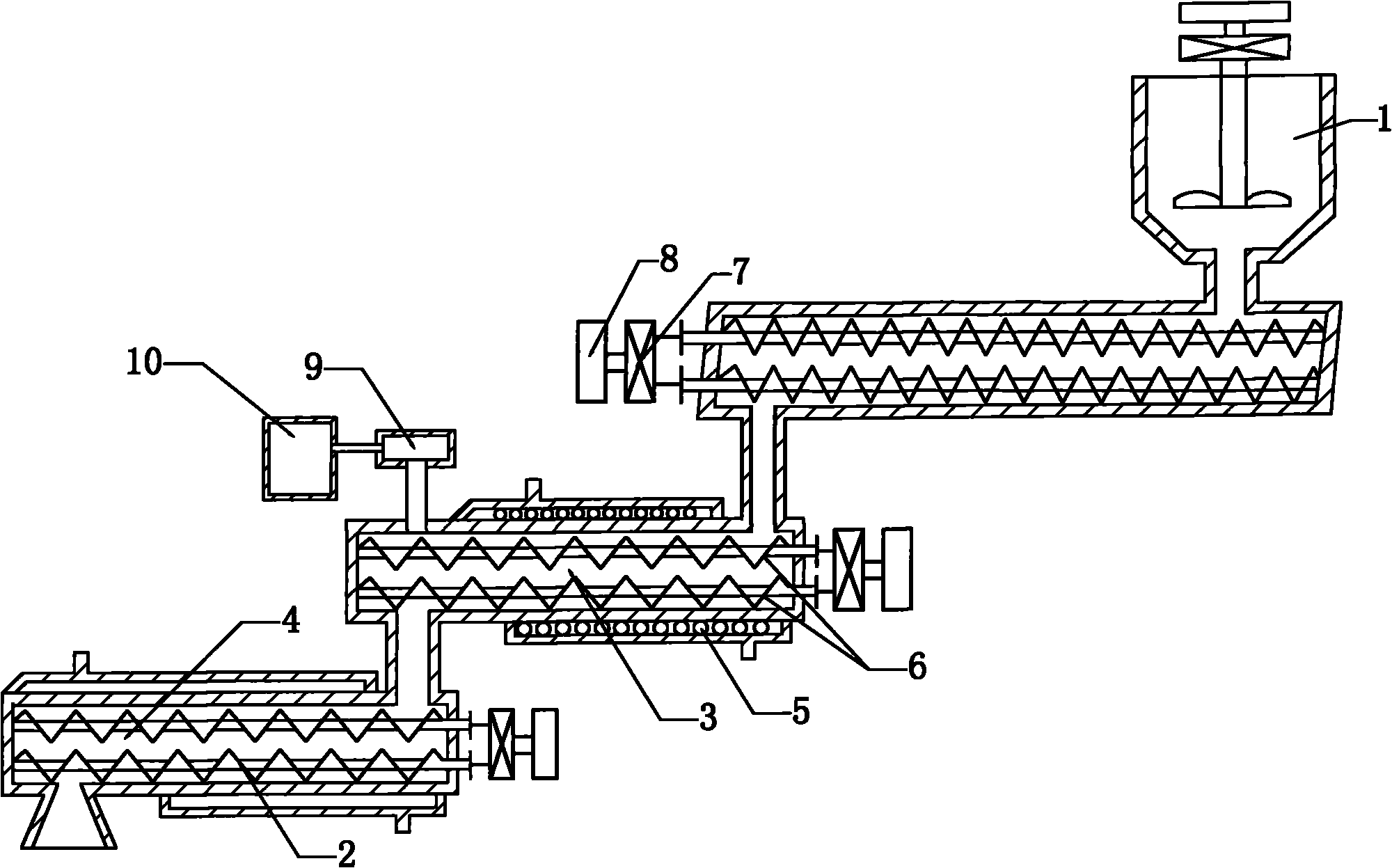

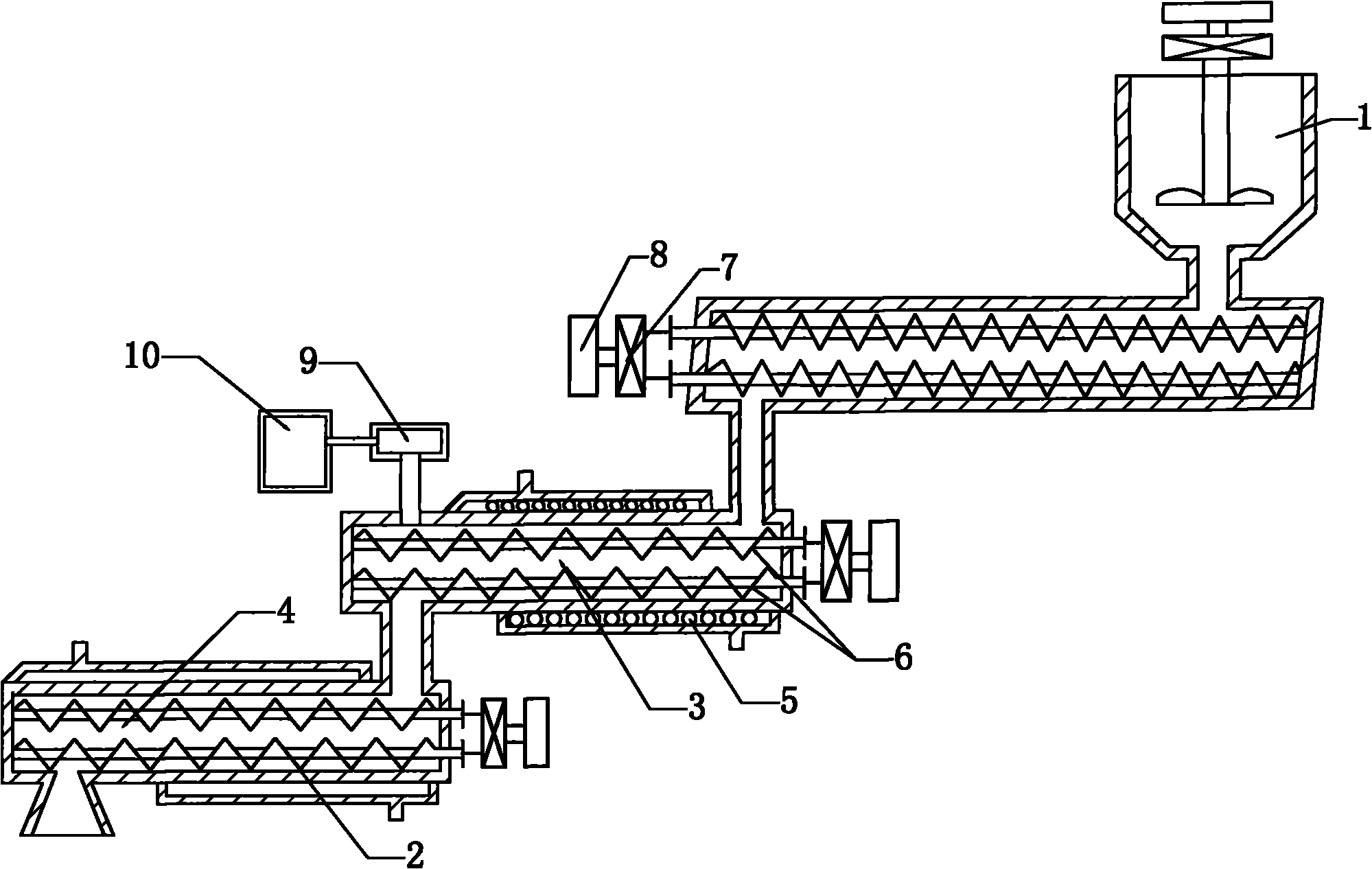

[0024] The production device of the environmentally friendly recovered rubber includes a stirring device 1, a feeding device 2, a plasticizing device 3 and a cooling device 4 connected in sequence, and is characterized in that: the heating device on the plasticizing device 3 is an electric heating device 5, and the plasticizing device 3 Both the device 3 and the cooling device 4 are equipped with a double-screw conveying device 6, and the double-screw conveying device 6 is controlled synchronously and reversely by two mutually meshing gears; the motors on the feeding device 2, the plasticizing device 3 and the cooling device 4 7 are all connected with the frequency converter 8, and the frequency converter 8 is connected with the computer control system;

[0025] In the production device of environmentally friendly recovered rubber, the plasticized rubber powder is transported through the double screw conveying device 6 in the plasticizing device 3 and the cooling device 4, whic...

Embodiment 2

[0027] Example 2:

[0028] The production method of the above-mentioned environmentally friendly restored rubber is to crush the waste rubber into rubber powder, add a certain proportion of activator and environmentally friendly oil, mix uniformly in the stirring device 1, and transport it into the plasticizing device 3 through the feeding device 2. Heating and plasticizing, cooling in the cooling device 4 to obtain plasticized rubber powder, sending the plasticized rubber powder into the rubber rolling process, kneading, thinning and refining to produce sheets.

[0029] The production method of the environment-friendly recovery rubber, its production steps are as follows:

[0030] Take 16-18 mesh rubber powder, mix for 40-50 minutes, plasticize at 220-240°C, and plasticize for 10-11 minutes for production:

[0031] Step 1, batching mixing: add activator and environment-friendly oil to the rubber powder pulverized to 16~18 purposes, by its weight ratio is rubber powder: activ...

Embodiment 3

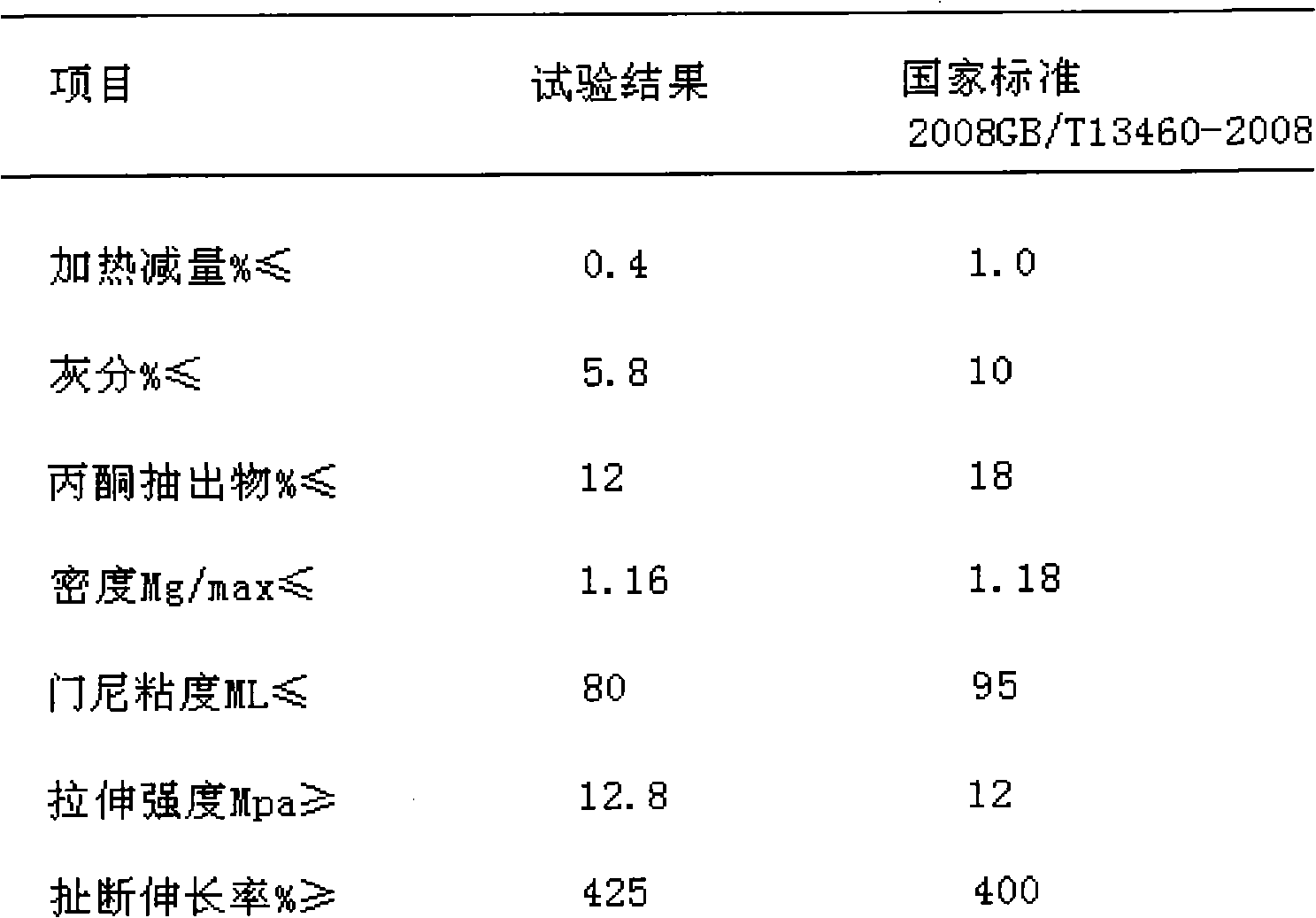

[0035] Take 18-20 mesh rubber powder, stir for 50-60 minutes, plasticize at 240-260° C., and plasticize for 11-12 minutes. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com