Water electrolysis system of solid polymer electrolyte

A solid polymer and water electrolysis technology, applied in the field of electrochemistry, can solve the problems of SPE water electrolysis system manufacturing difficulties, limited temperature control measures, poor explosion-proof performance, etc., and achieve easy and accurate safety detection and improved purging efficiency , Improve the effect of explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

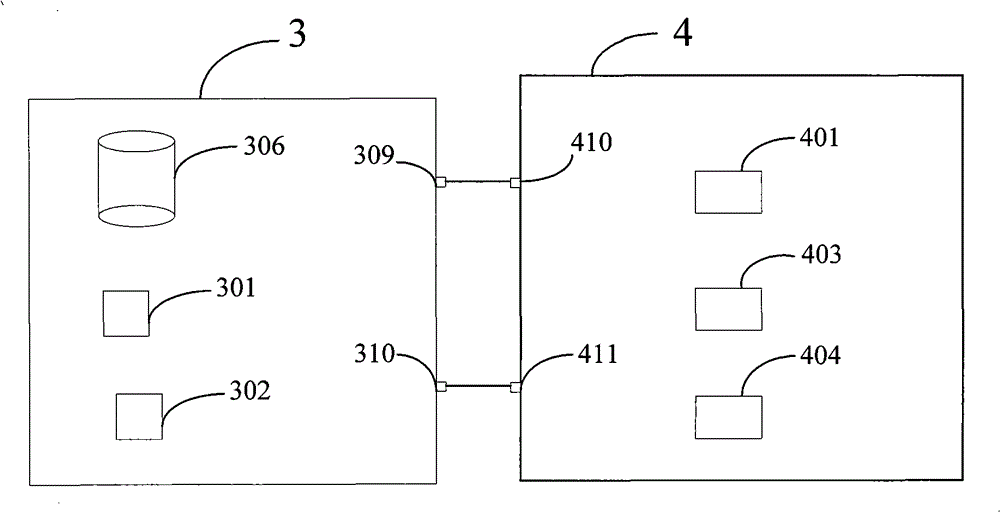

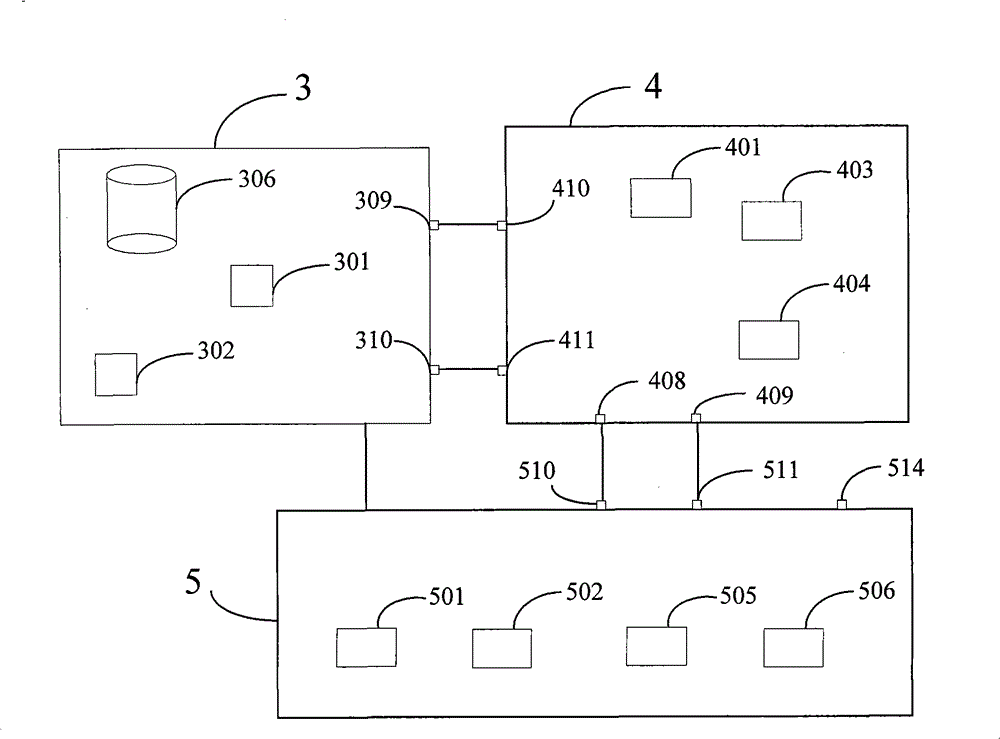

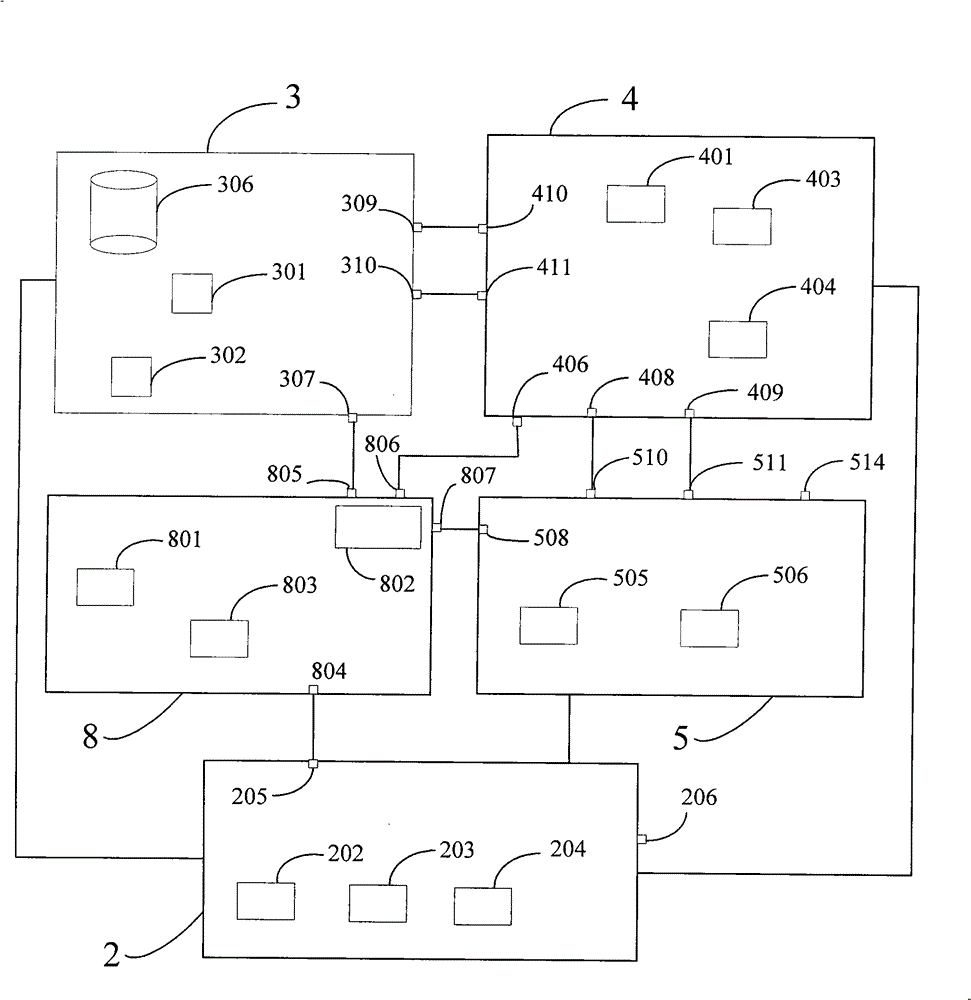

[0030] The structure and working method of the SPE water electrolysis system in the embodiment of the present invention will be described below with reference to the accompanying drawings. In order to make the SPE water electrolysis system easy to prepare and modify, and improve its explosion-proof performance, in the embodiment of the present invention, a structure of the SPE water electrolysis system is as follows figure 1 As shown, a water supply device 3 and an electrolysis device 4 are included. The water supply device 3 is used to supply water to the electrolysis device 4 and store the water discharged from the electrolysis device 4 . The electrolysis device 4 is used to electrolyze water to generate hydrogen and oxygen, and perform primary gas-liquid separation on the generated gas, and discharge the water therein. The primary gas-liquid separation here generally only discharges most of the water mixed in hydrogen and oxygen. If the gas is further dried, other drying e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com