Full automatic colour roller printing, drying and burnt-out equipment

A roller printing, fully automatic technology, applied to textiles, papermaking, fabric surface trimming, etc., can solve the problems of poor pressure bearing capacity of steamer, low product grade, lack of color, etc., and achieve good pressure bearing and sealing performance, processing Effects of cost reduction and high equipment reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

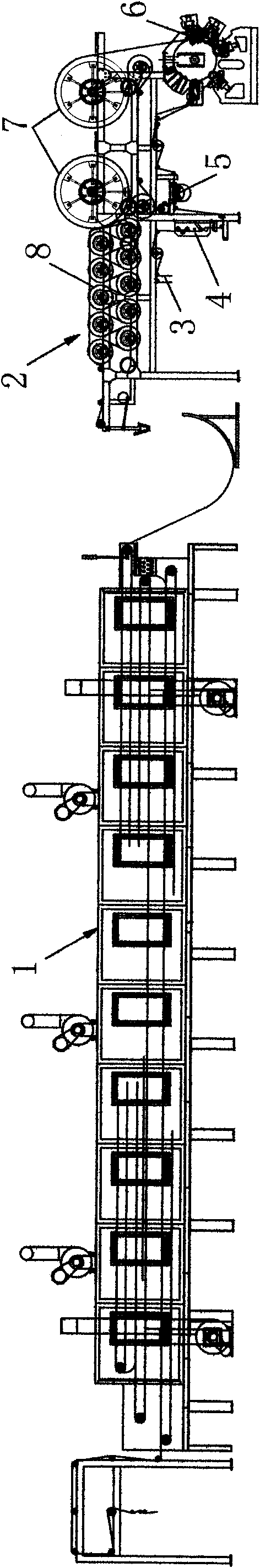

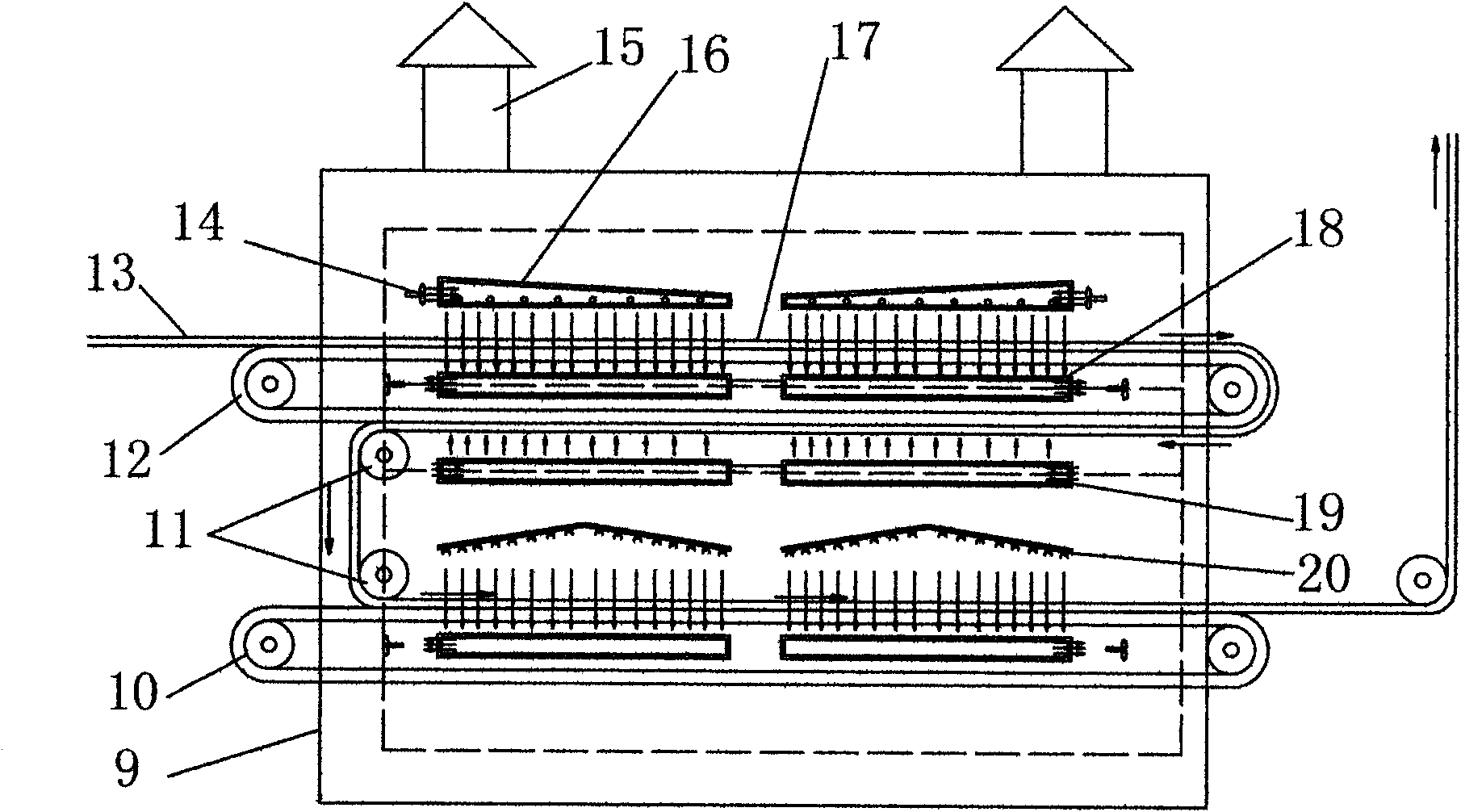

[0025] As shown in the figure, the present invention includes a color roller printing device 2 and an infrared drying device 1 for color development and burn-out.

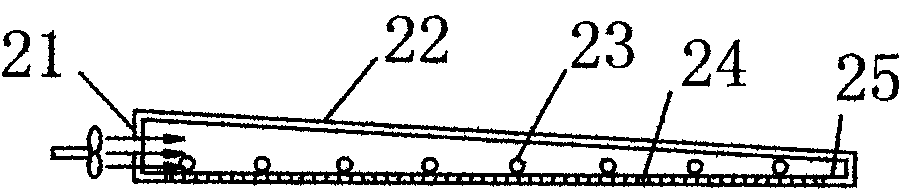

[0026] The color roller printing device includes a deviation correction device 4, a dust suction device 5, a color roller coloring device 6, and a cylinder flattening drying device. The deviation correction device and the dust suction device are installed at the feeding place of the fabric 3, and the A color roller coloring device 6 is provided at the subsequent process position of the dust suction device, and a cylinder flattening and drying device is provided at the subsequent process position of the color roller coloring device, and the cylinder flattening and drying device includes multiple A small heating cylinder 8 and a large heating cylinder 7 are closely fitted and connected success...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com