Construction method for newly increasing arched open cut tunnel at railway operating line tunnel portal

A construction method and operation line technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as low construction efficiency, complicated process, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

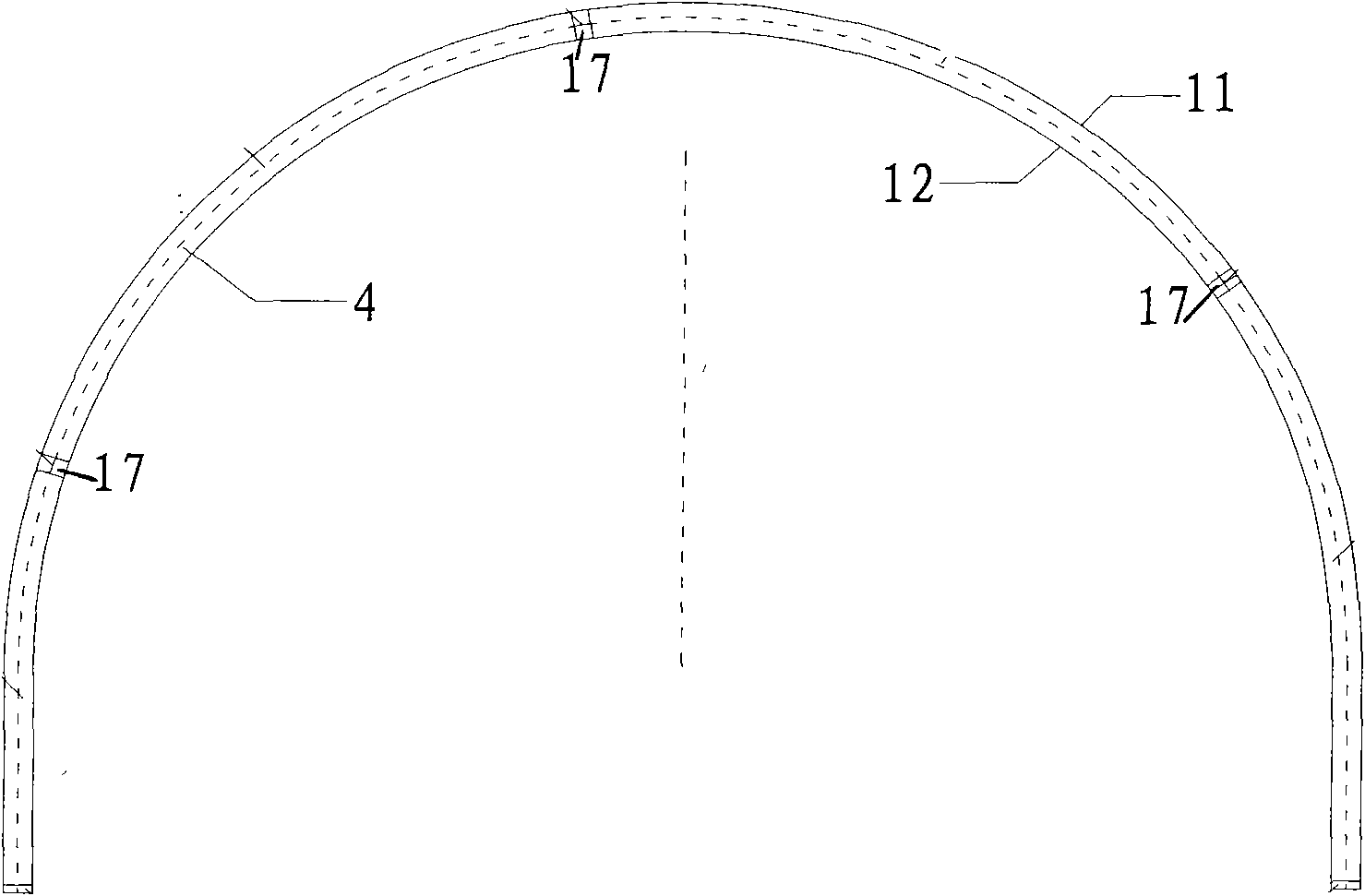

[0039] A construction method for adding an arched open hole to a railway operation line tunnel, comprising the following steps:

[0040] A. Measurement stakeout

[0041] Before construction, carry out measurement and lofting, check the central mileage and axis position of the pile position and the arched open hole, measure the original ground elevation, and determine the drilling position and depth;

[0042] B. Manual excavation pile construction

[0043] a.Process flow

[0044] Pile hole measurement and positioning→hole digging→reinforced concrete lock→pile body digging→pour retaining concrete→circular footage reaching the design depth→reinforcement cage fabrication and installation→pile body concrete pouring→concrete curing.

[0045] In order to ensure the static acceptance results, during the construction of the excavated piles, the settlement observation of the rails on the line should be carried out.

[0046] b. Construction method

[0047]After the hole pile position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com