Composite energy storage and supply device via thermochemical temperature swing adsorption combined cold-heat supply

A technology of chemical variable temperature and composite energy storage, which is applied in the direction of heating and cooling combination, energy-saving heating/cooling, refrigerator, etc. It can solve the problems of large output temperature fluctuations, low output temperature of heat pump devices, and difficulty in matching external users, etc., to achieve High energy storage density, improved energy grade, and long-term storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

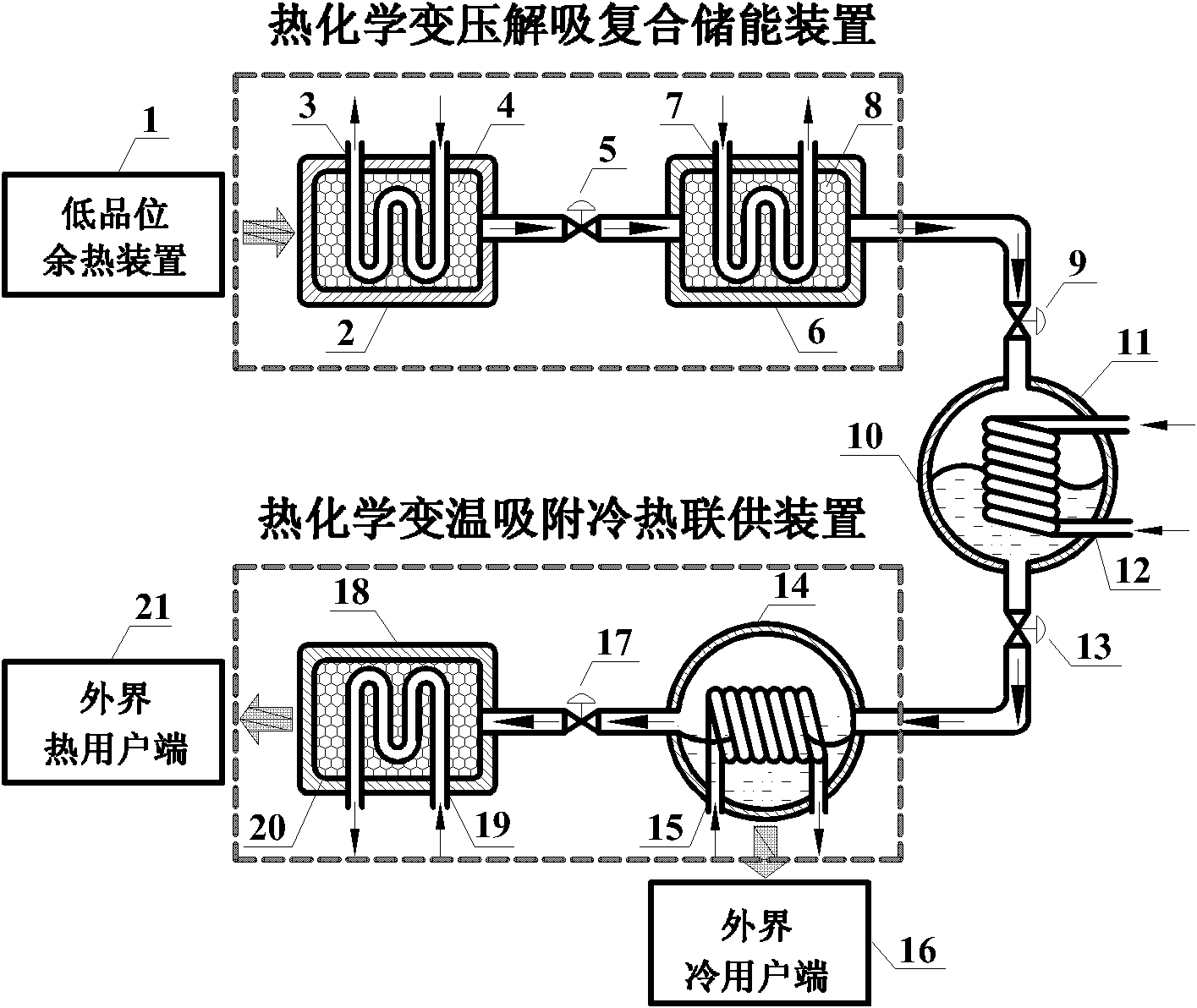

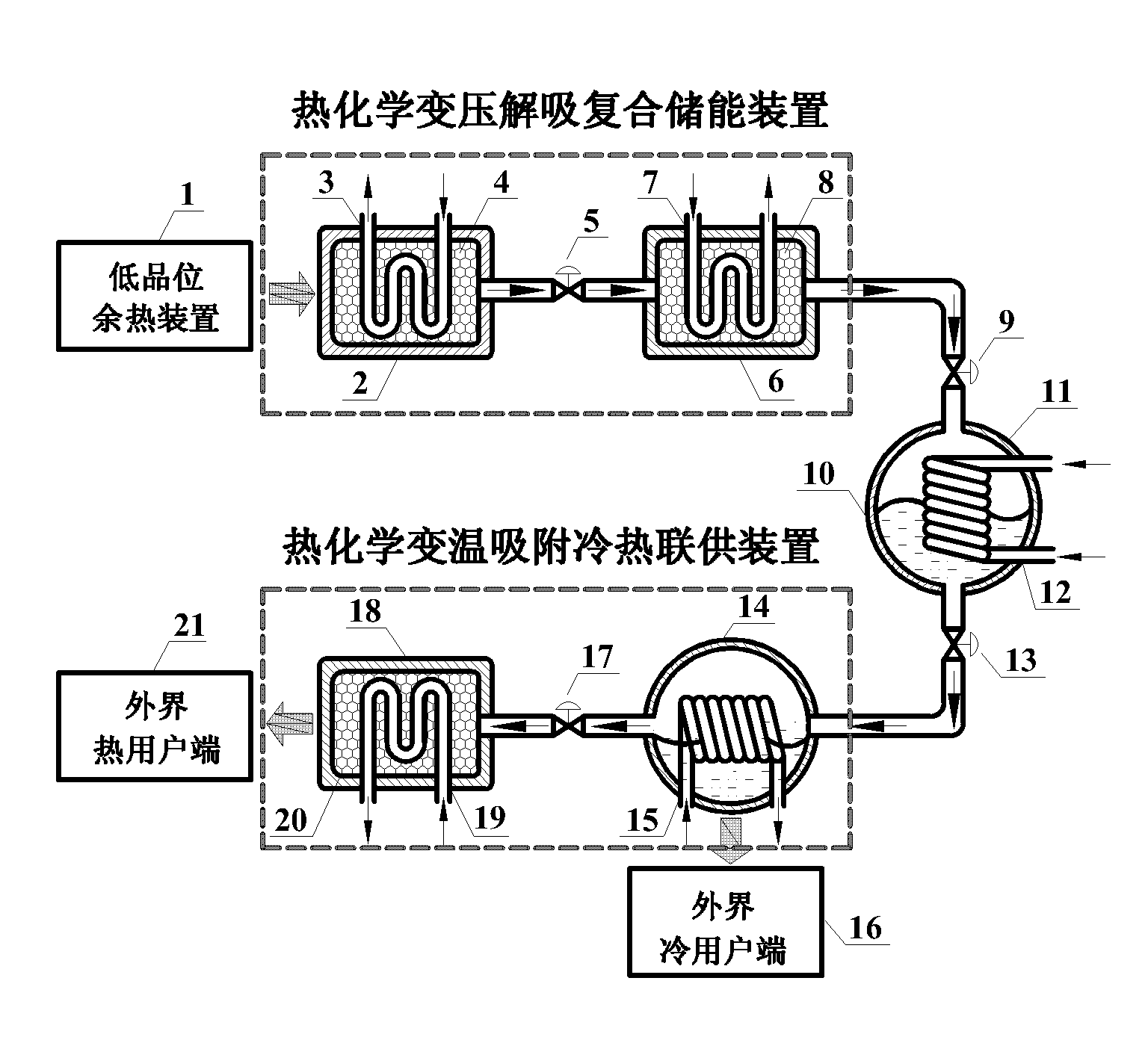

[0030] Such as figure 1 As shown, this embodiment includes: low-grade waste heat device 1, energy storage solid-gas reactor 2, energy storage reactor heat exchange coil 3, energy storage chemical adsorption material 4, first refrigerant regulating valve 5, auxiliary solid - gas reactor 6, auxiliary reactor heat exchange coil 7, auxiliary chemical adsorption material 8, second refrigerant regulating valve 9, refrigerant 10, condenser 11, condenser heat exchange coil 12, third refrigerant regulating Valve 13, high / low temperature evaporator 14, evaporator heat exchange coil 15, fourth refrigerant regulating valve 17, energy supply solid-gas reactor 18, energy supply reactor heat exchange coil 19 and energy supply chemical adsorption material 20, wherein: the low-grade waste heat device 1 is connected to the heat exchange coil 3 of the energy storage reactor, the outlet of the energy storage solid-gas reactor 2 is connected to the inlet of the first refrigerant regulating valve 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com