Special-shaped wire section forming device

A wire and special-shaped technology, applied in the direction of metal rolling, can solve problems such as wire bending, and achieve the effect of suppressing bending and improving manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

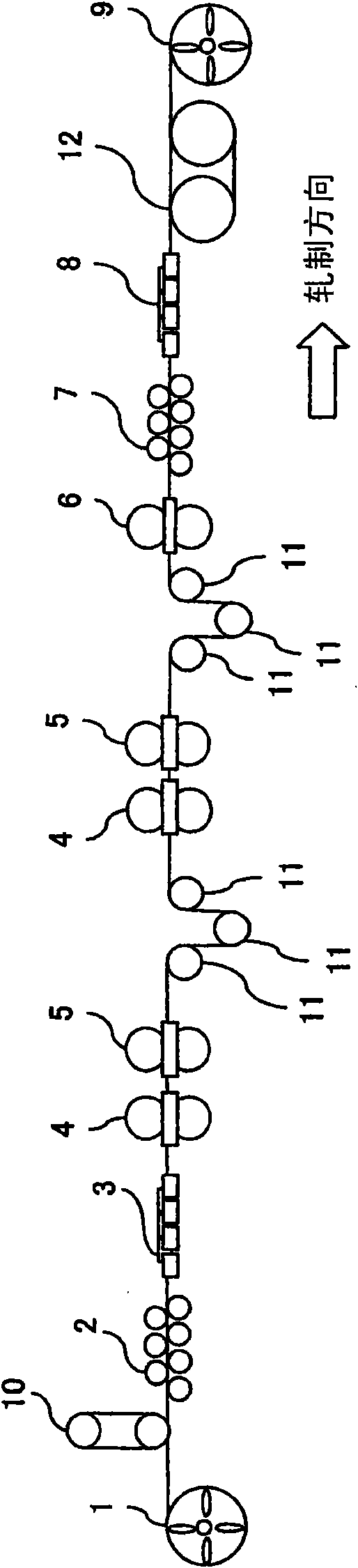

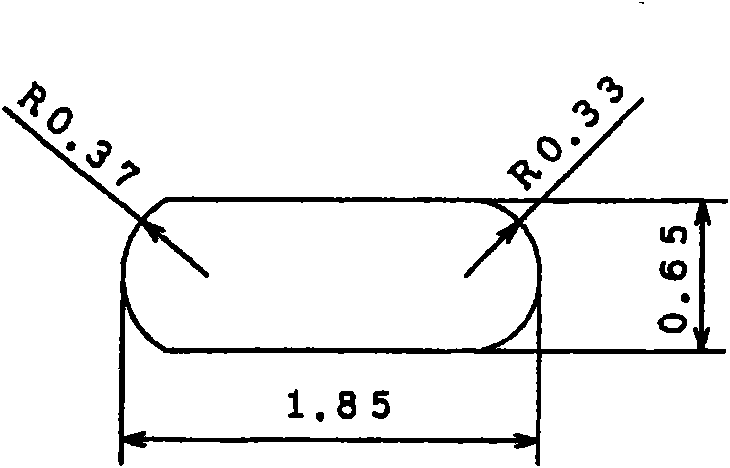

[0051] Such as figure 1 As shown, rolling is carried out by adopting the forming device of the following special-shaped wire rods: a pressure accumulating jumping roller 10, a front roller straightening machine (up and down direction) 2, a front roller straightening machine (horizontal direction) 2, and a front roller straightening machine (horizontal ) 3, in its rear segment, the forming units arranged in series by the non-driven four-roller cross-shaped roll die 4 and the power-driven four-roller cross-shaped roll die 5 are arranged in series, and 2 units are arranged in series, and in the rear segment of the forming unit, Equipped with a finishing unit consisting of a non-driven four-roller cross-shaped roll die 6, a rear roller leveler (vertical direction) 7, a rear roller straightener (horizontal direction) 8, and a double drum winch 12 , winding machine 9. Among the raw materials, 0.8%C-17%Cr steel (mass%) with a diameter of Φ1.38mm is used, and it is shaped as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com