Non-in-situ prepressing method of self-anchored type support frame and self-anchored type support frame thereof

A self-anchoring, non-in-situ technology, which is applied in the construction of large-tonnage structure supports and high piers, can solve the problems of limited maximum lifting capacity of tower cranes, inability to guarantee the construction period, and time-consuming operation, so as to ensure the construction quality easily and save Temporary materials used for construction, clear force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

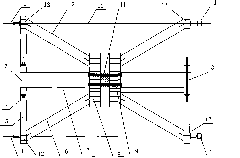

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

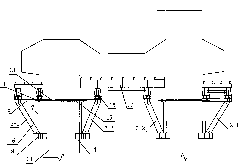

[0030] image 3 It is the elevation layout drawing of the present invention in the embodiment of the 0# block support of Xinmin Minjiang Super Bridge,

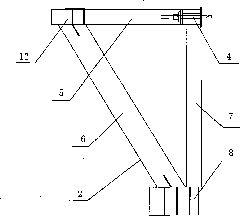

[0031] This 0# block is a single-box single-chamber structure, and the self-anchoring bracket method is used for cast-in-place construction, that is, the supporting crossbar 8 of the self-anchoring bracket 2 extends into the pier hole 14 of the side wall of the pier body 13, The two self-anchored brackets 2-1 and 2-2 on the left and right sides of the pier body 13 are anchored on the pier body 13 by using the precision-rolled rebar 15 to pull between the horizontal tie rods 5 on the upper part of the self-anchored bracket 2 , forming a self-anchored system, 2I56a is arranged on the top of the horizontal tie rod 5 of the self-anchored bracket 2 as the main bearing beam 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com