Split type vibration slag cooler with multiple vibration sources for circulating fluidized bed boiler

A circulating fluidized bed and split-type technology, which is applied in the field of auxiliary equipment, can solve the problems of high maintenance labor intensity, uneven distribution, and large local wear of cooling pipe rows, etc., and achieves reduced maintenance labor intensity, low slag discharge temperature, and easy The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

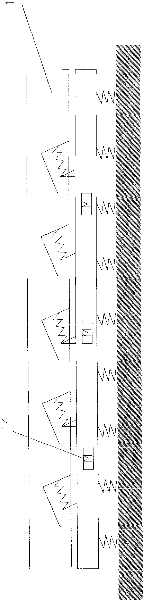

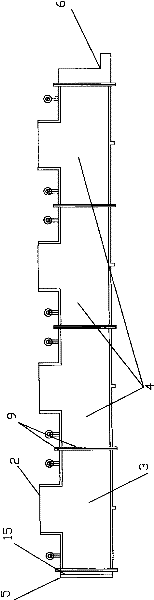

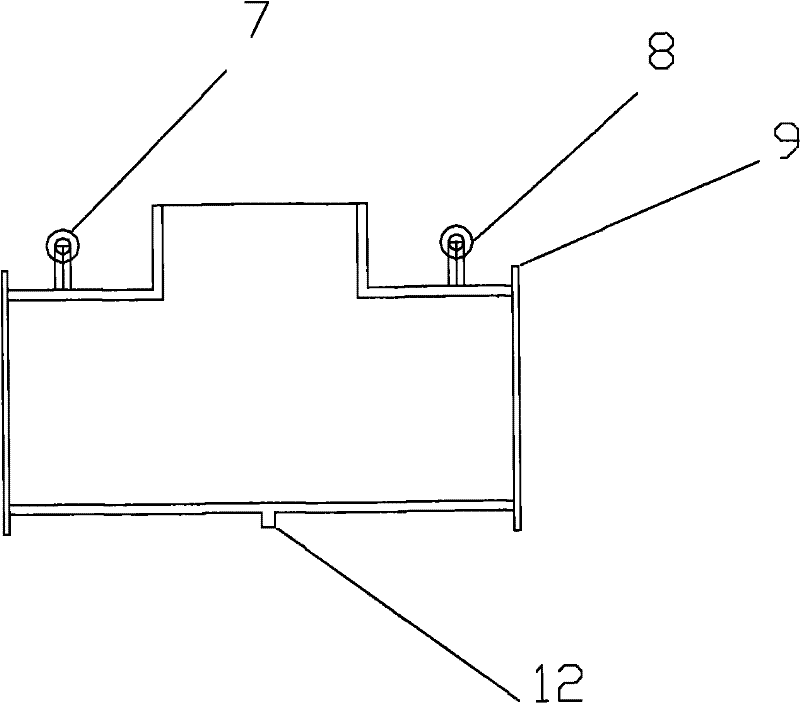

[0019] like figure 1 , 2 , 3, and 4, a multi-source split-type vibration slag cooler for a circulating fluidized bed boiler in this embodiment includes a support structure 1 and a cooling cylinder 2, the cooling cylinder 2 is installed on the support structure 1, Moreover, the outer wall of the cooling cylinder 2 is provided with a sandwich shell; the cooling cylinder 2 is composed of a slag-feeding section 3 and a middle section 4, and the lengths of the slag-feeding section 3 and the middle section 4 are equal. And the inside of the cooling cylinder 2 is equipped with a cooling pipe row 11, and the cooling pipe row 11 is provided with an inner screw, which can increase the heat exchange area; a detachable mesh screen 15 is installed at the entrance of the slag feeding section 3; the cylinder is vibrated to make the The fine slag falls naturally from the sieve holes, and the large pieces are left on the sieve, which can be taken out manually. Before the detachable mesh scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com