Laser measuring device for measuring thickness of plate

A technology of laser measurement and sheet metal, applied in measurement devices, optical devices, instruments, etc., can solve the problems of device service life, installation difficulties, laser effects, etc., to achieve the weakened effect of high temperature and steel chips, easy installation, and heat The effect of radiation impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

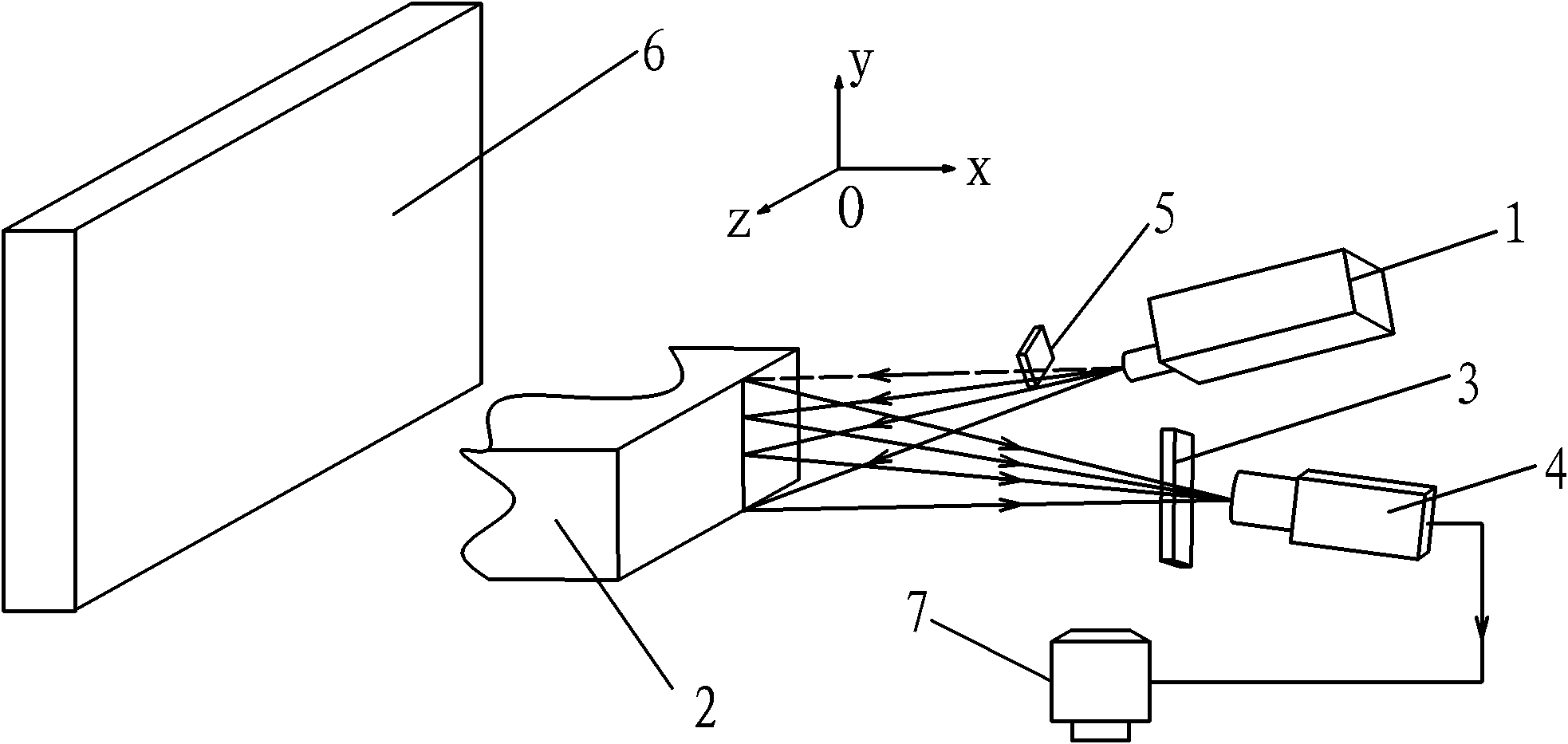

Method used

Image

Examples

Embodiment

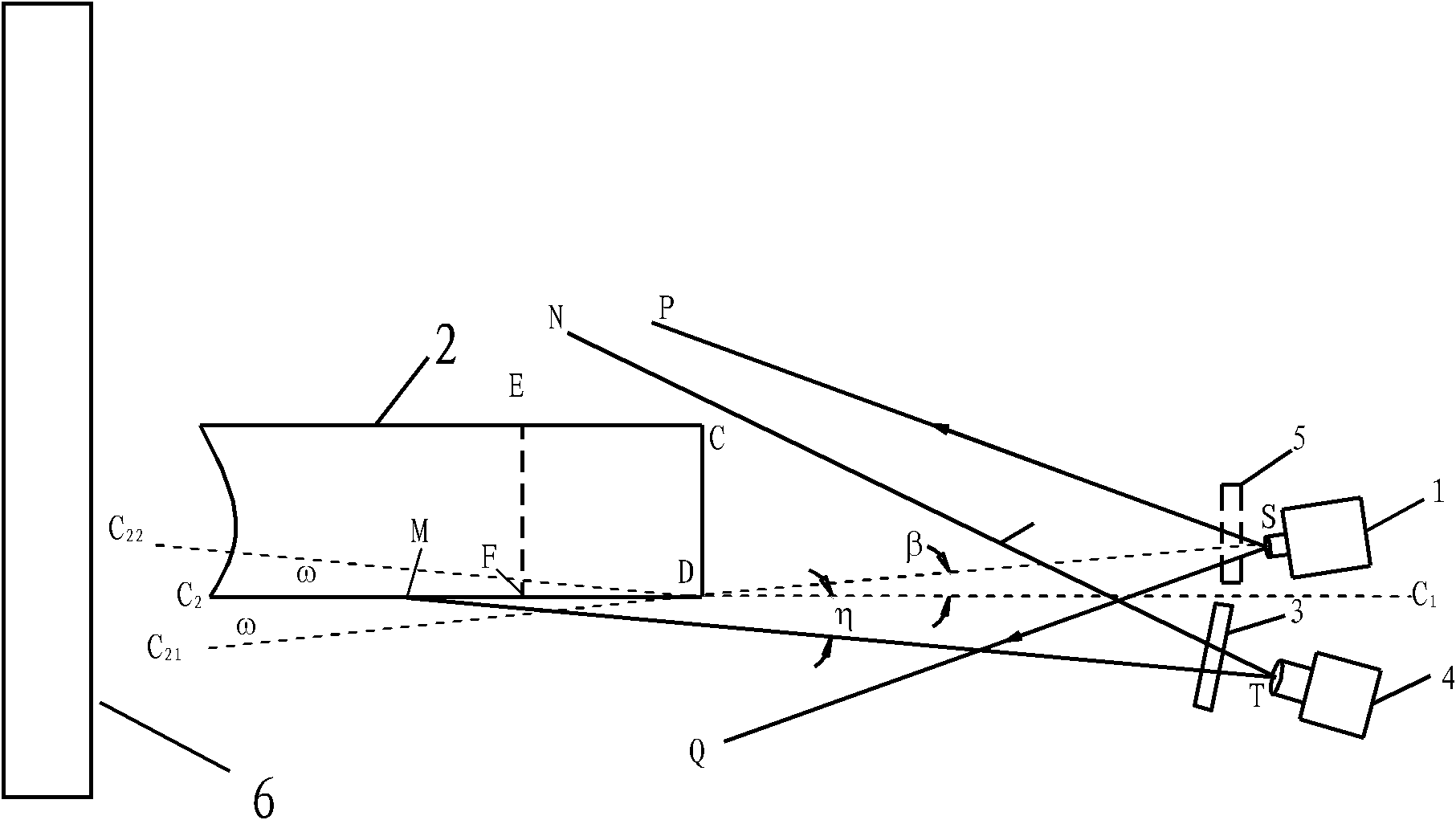

[0043] figure 2 Among them, the thickness range of the tested board 2 is 120mm, the horizontal distance between the laser outlet and the tested board 2 is 1500mm, and the height from the bottom surface of the tested board 2 is 210.6mm; β=8°

[0044] exist image 3 Among them, the angle between the main axis of the laser and the optical axis of the camera is 26.5°; the angle between the light in the field of view under the camera and the horizontal line is η=8.05°.

[0045] Plate bottom inclination range -8°<ω<8°

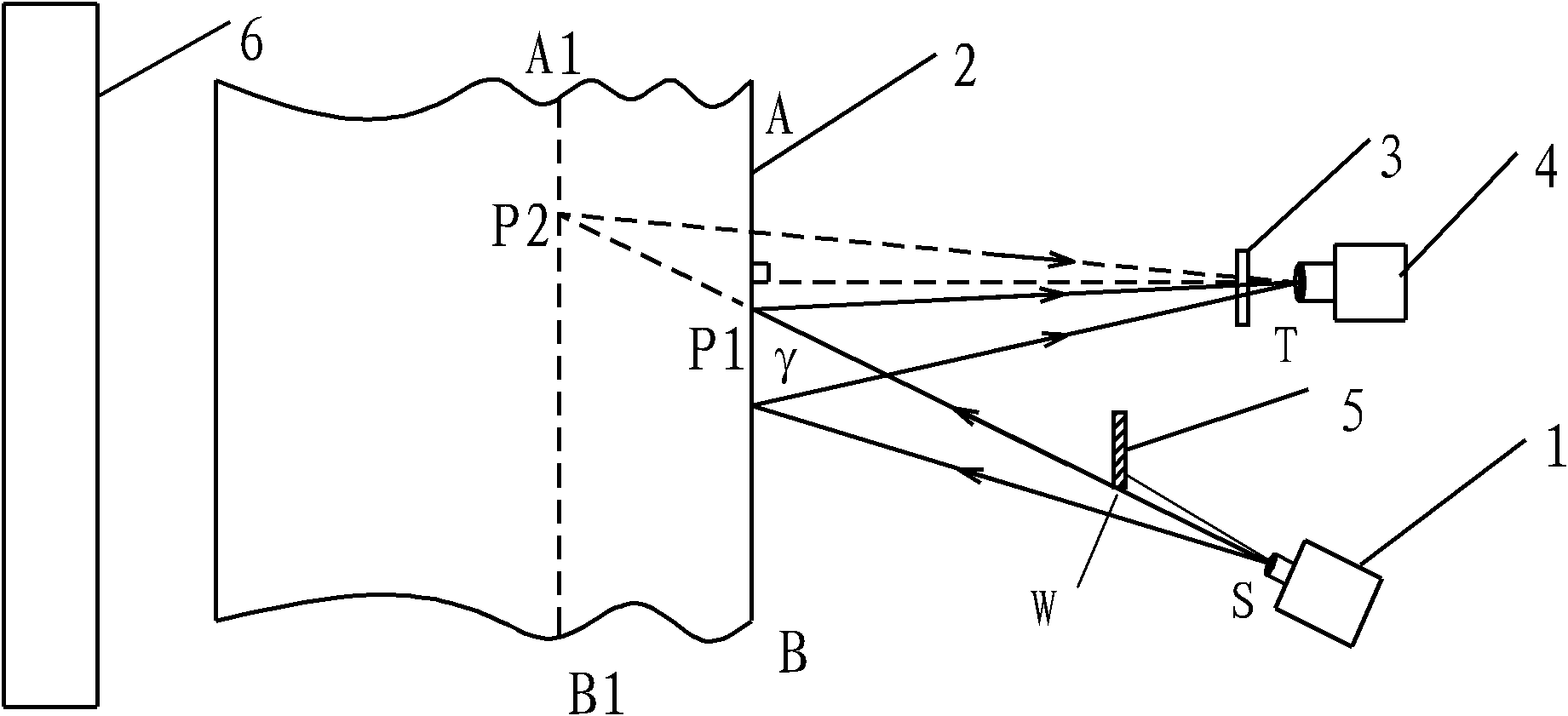

[0046] The CCD pixel size of the camera sensor used is: 7.6μm×7.6μm, and the number of pixels is 1600×1200;

[0047] The focal length of the imaging lens used is 75 mm, the horizontal distance between the lens and the tested board 2 is 1500 mm, and the distance between the lens aperture T and the lower surface of the tested board 2 is 240 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com