Implanted bioelectrode based on photoetching and other micro-nano manufacturing technologies and preparation method thereof

A micro-nano manufacturing and biological electrode technology, applied in electrodes, internal electrodes, metal material coating processes, etc., can solve the problems of complex manufacturing process and large electrode stimulation point size, avoiding winding and welding, small size, Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

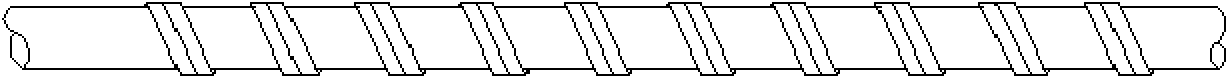

[0014] Take 2 stimulus points as an example. The electrode of the present invention is divided into a connecting end, a connecting line and a stimulating end. The connecting end includes two metal rings 3, and the stimulating end includes two stimulating points 1.

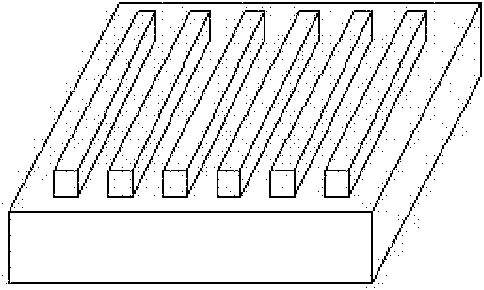

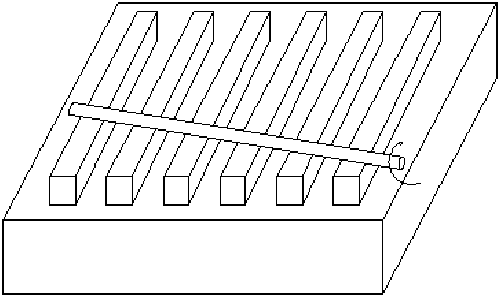

[0015] refer to figure 1 , 2 , 3, first, sputter a layer of titanium film with a thickness of 0.0025mm on the polyurethane sleeve, and then sputter a silver film (or gold, or platinum, or iridium) with a thickness of about 0.03mm on it, Titanium here is used as an adhesion promoter to enhance the adhesion strength of the silver film to the polyurethane tube, and then use the elastic mold made by the photolithography process (such as figure 1 Shown) on the surface of the capillary sputtered with silver layer embossed (such as figure 2 Shown) hexadecanethiol (hexadecanethiol) helical wire, the imprinted tube is immersed in ferricyanide solution to remove the silver film not protected by hexadecanethiol, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com