Air diffusion aerator

A technology of aerator and air intake pipe, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of complex structure, poor oxygen mass transfer effect, high price, etc. The effect of high oxygen mass transfer efficiency, small bubbles and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

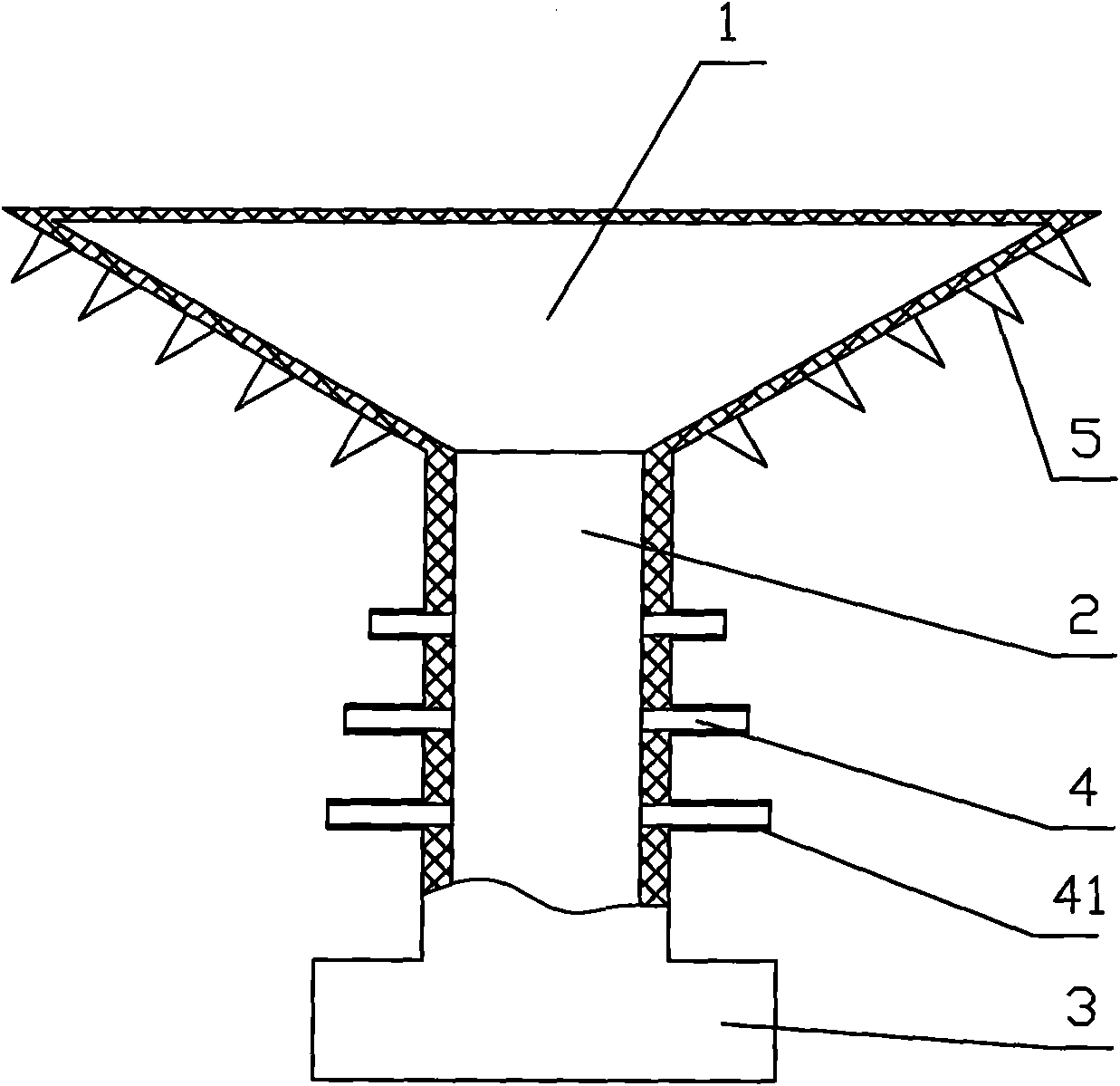

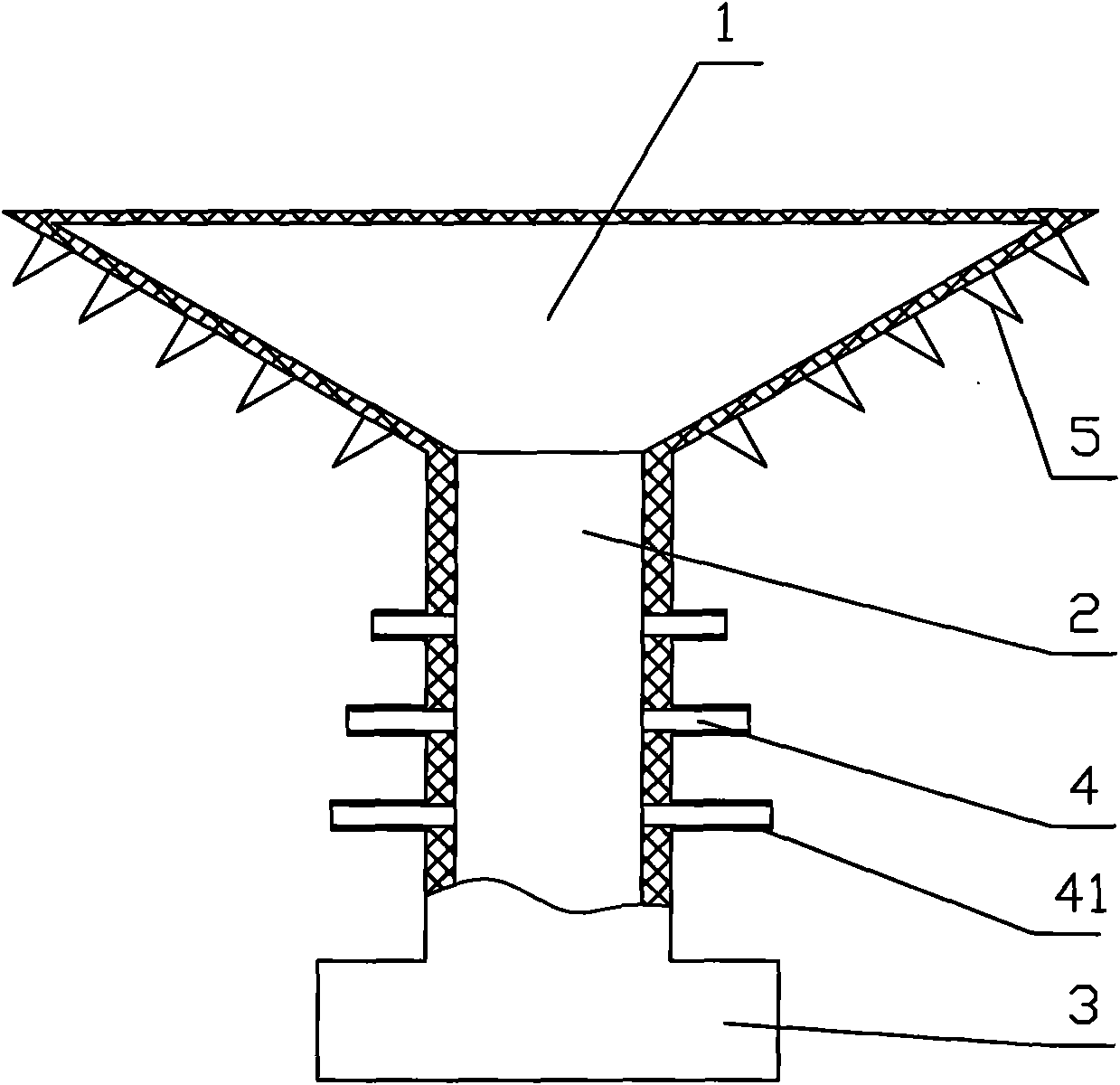

[0012] Such as figure 1 As shown, it is an embodiment of a diffuse aerator of the present invention, comprising an air intake pipe 3 and an inverted umbrella cover 1, the upper end of the air intake pipe 3 is connected to the lower end of the inverted umbrella cover 1 through a perforated pipe 2, and the perforated pipe 2 The four walls are provided with several microholes 4 penetrating through the wall of the perforated pipe. The perforated tube is cylindrical. The tube wall of the perforated tube is provided with three layers of micropores 4, and each layer of micropores is provided with 4 to 8 micropores which are evenly distributed on the circumference of the tube wall of the perforated tube. The wall of the perforated tube at the microhole is provided with extension conduits 41 with the same or different extension lengths. In this embodiment, the length of the extension conduits gradually increases from top to bottom. At least two layers of conical teeth 5 are distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com