Method for treating high-concentration formaldehyde wastewater by using waste alkali

A high-concentration formaldehyde and alkali treatment technology, applied in the environmental field, can solve complex problems, achieve the effects of improving impact resistance, avoiding scaling, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

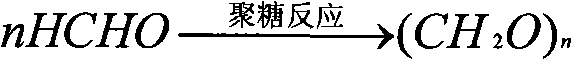

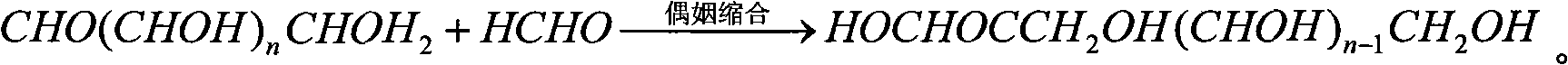

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: process certain formaldehyde waste water with the inventive method.

[0025] The sources of waste water are: A. Workshop waste water, with a water volume of 41.6m 3 / h; B, domestic wastewater, water volume 7.7m 3 / h; C, initial rainwater, water volume 96m 3 / Second-rate;

[0026] The design influent formaldehyde concentration of wastewater is about 6900mg / L, and the pH is 3.5.

[0027] The specific steps are as follows:

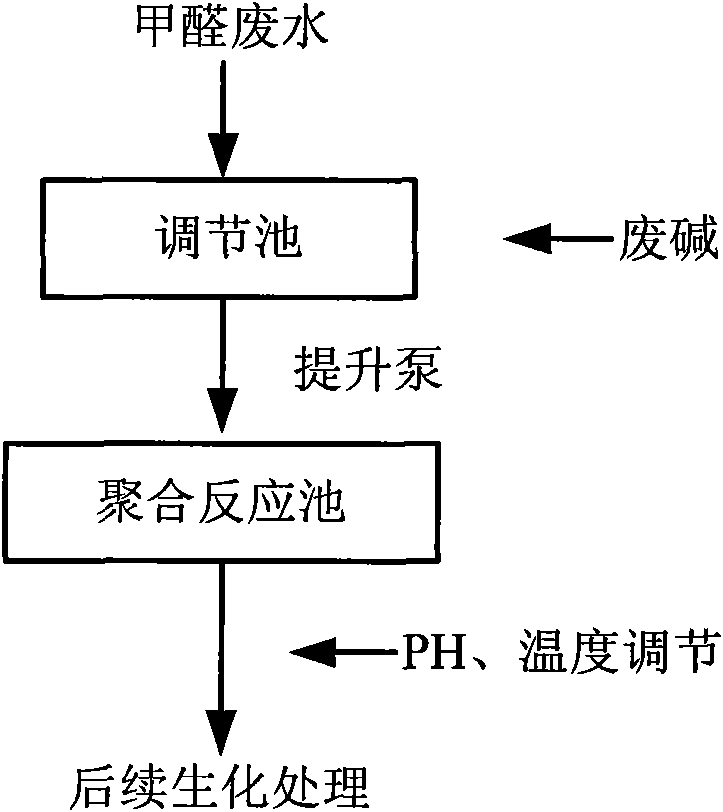

[0028] (1) After the waste water passes through the grille, it directly enters the regulating tank, which is equipped with a vertical circulation mixer, and the high-speed stirring ensures that the water quality is evenly mixed. The hydraulic retention time of the adjustment tank is 24 hours, and it is pumped into the polymerization reaction tank through the primary lift pump.

[0029] (2) The effluent obtained in step (1) enters the polymerization reaction tank, and the polymerization reaction tank is provided with a frame mixer, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com