Method for preparing celastrine

A technology of shertenin and ultrasound, which is applied in the field of preparation of shertenin from plants, can solve the problems of no disclosure of the industrial production process of shertenin, and achieve the benefits of large-scale production operations, low energy consumption, The effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

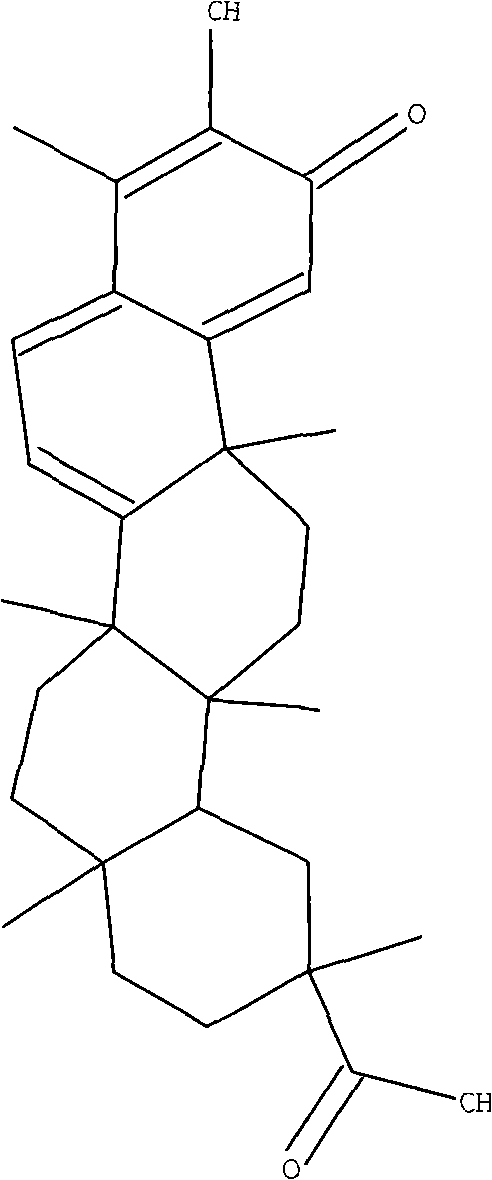

Image

Examples

Embodiment 1

[0017] Take the keratin root bark of Euonymus plant, crush it, add methanol 4 times its mass and volume, put it into an ultrasonic extraction device for ultrasonic extraction once, each time for 0.2 hours, the extraction power is 30KHZ, combine the extracts, filter, reduce Recover methanol under pressure, dissolve the residue by adding 0.05mol / L NaOH aqueous solution, filter, adjust the pH value of the filtrate to 3 with dilute hydrochloric acid solution, let it stand, filter, take the filter residue, add it to the alumina chromatography column, and use volume Elute with methanol-chloroform mixed solvent with a ratio of 3:1, collect 2 times the column volume of the eluate, recover the solvent under reduced pressure and concentrate, add ethanol-n-hexane mixed solvent with a volume ratio of 1:1 for crystallization, and separate the crystallization That is, 5.2 g of shertenin was obtained, and the purity was 98.0% as detected by HPLC.

Embodiment 2

[0019] Take 10Kg of Euonymus plant kerosene root bark, crush it, add methanol with 5 times the volume of its mass, put it into an ultrasonic extraction device for ultrasonic extraction 3 times, each time for 1 hour, the extraction power is 60KHZ, combine the extracts, filter, Recover methanol under reduced pressure, add 0.15mol / L NaOH aqueous solution to the residue to dissolve, filter, adjust the pH value of the filtrate to 5 with dilute hydrochloric acid solution, let it stand, filter, take the filter residue, add it to the alumina chromatography column, use The methanol-chloroform mixed solvent with a volume ratio of 3:1 was eluted, and 4 times the volume of the column volume was collected. Crystallization yielded 9.2 g of shertenin, which was detected by HPLC with a purity of 96.6%.

Embodiment 3

[0021] Take 10Kg of Euonymus plant kerosene root bark, crush it, add methanol with 3 times the volume of its mass, put it into an ultrasonic extraction device for ultrasonic extraction twice, each time for 0.5 hours, the extraction power is 50KHZ, combine the extracts, filter, Recover methanol under reduced pressure, add 1mol / L NaOH aqueous solution to the residue to dissolve, filter, adjust the pH value of the filtrate to 4 with dilute hydrochloric acid solution, let it stand, filter, take the filter residue, add it to an alumina chromatography column, and use volume Elute with a mixed solvent of methanol-chloroform with a ratio of 3:1, collect 3 times the column volume of the eluate, recover the solvent under reduced pressure and concentrate, add a mixed solvent of ethanol-n-hexane with a volume ratio of 1:1 for crystallization, and separate the crystals That is, 8.8 g of shertenin was obtained, and the purity was 98.9% as detected by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com