Ceramic floor tile paving device

A technology of floor tiles and ceramics, applied in construction, building structure and other directions, can solve the problems of reducing labor efficiency and subsequent paving quality, laborious handling of workers, and far center of gravity of objects to be handled, achieving good paving quality, reducing labor intensity, Improve the effect of paving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

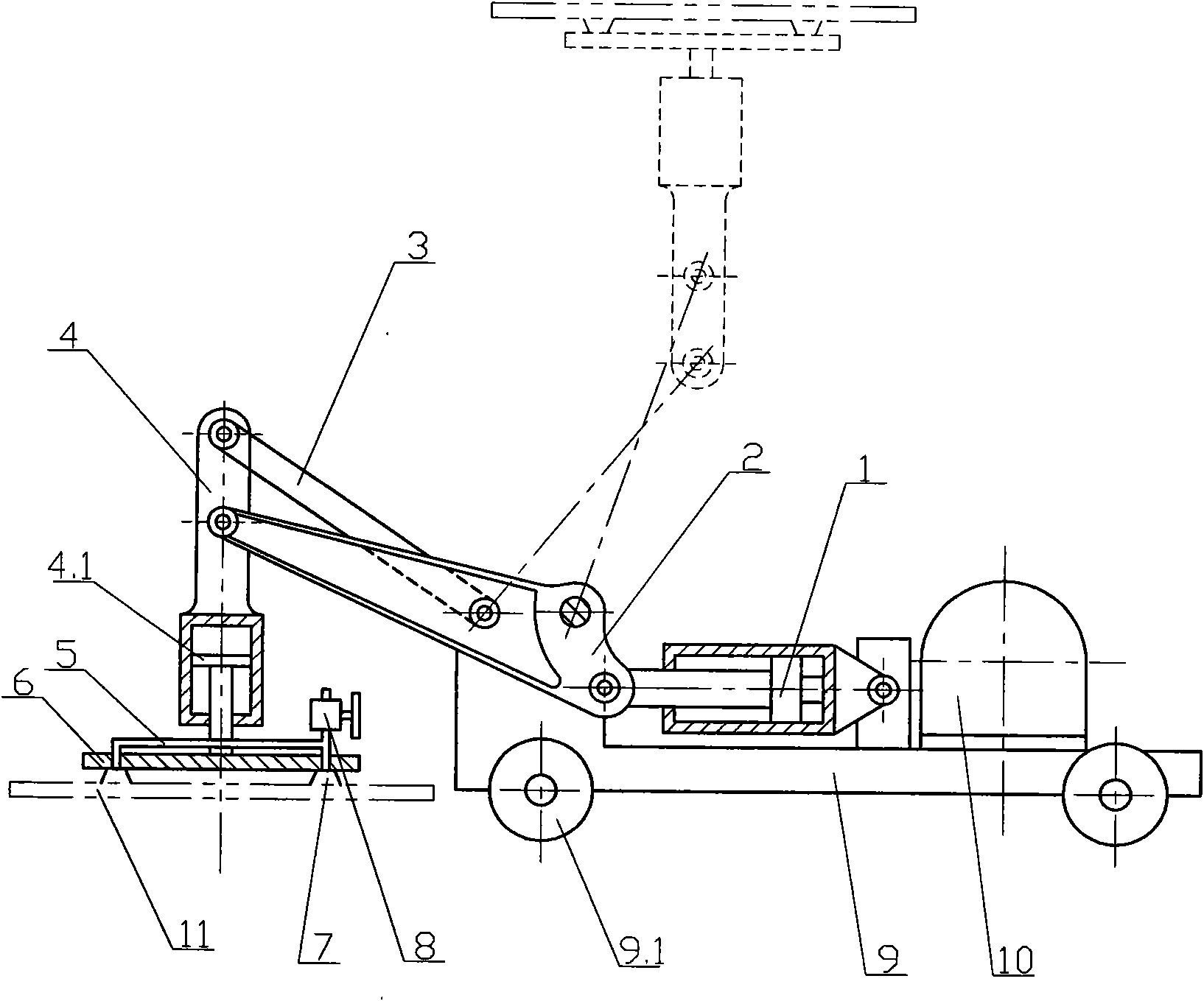

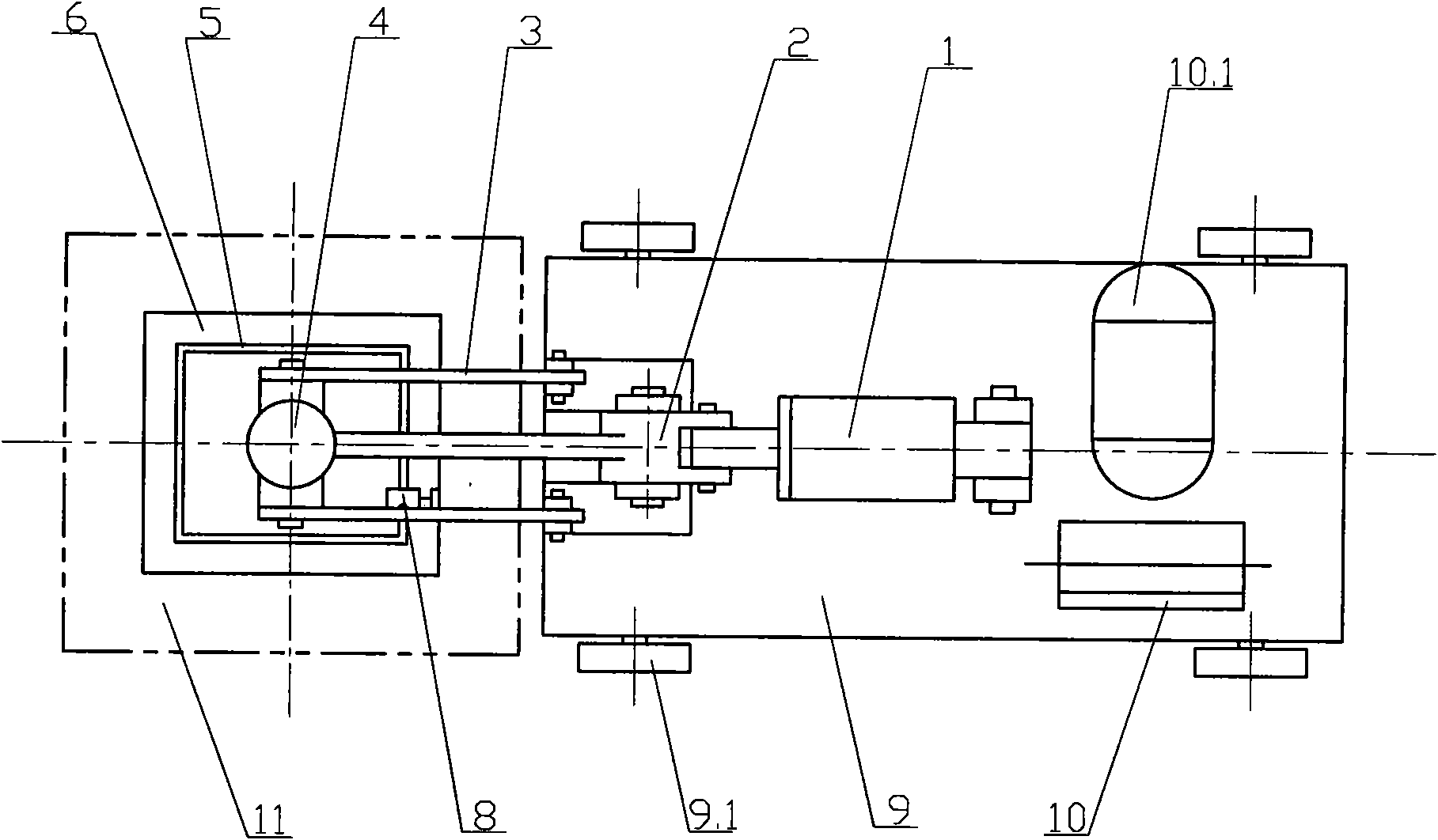

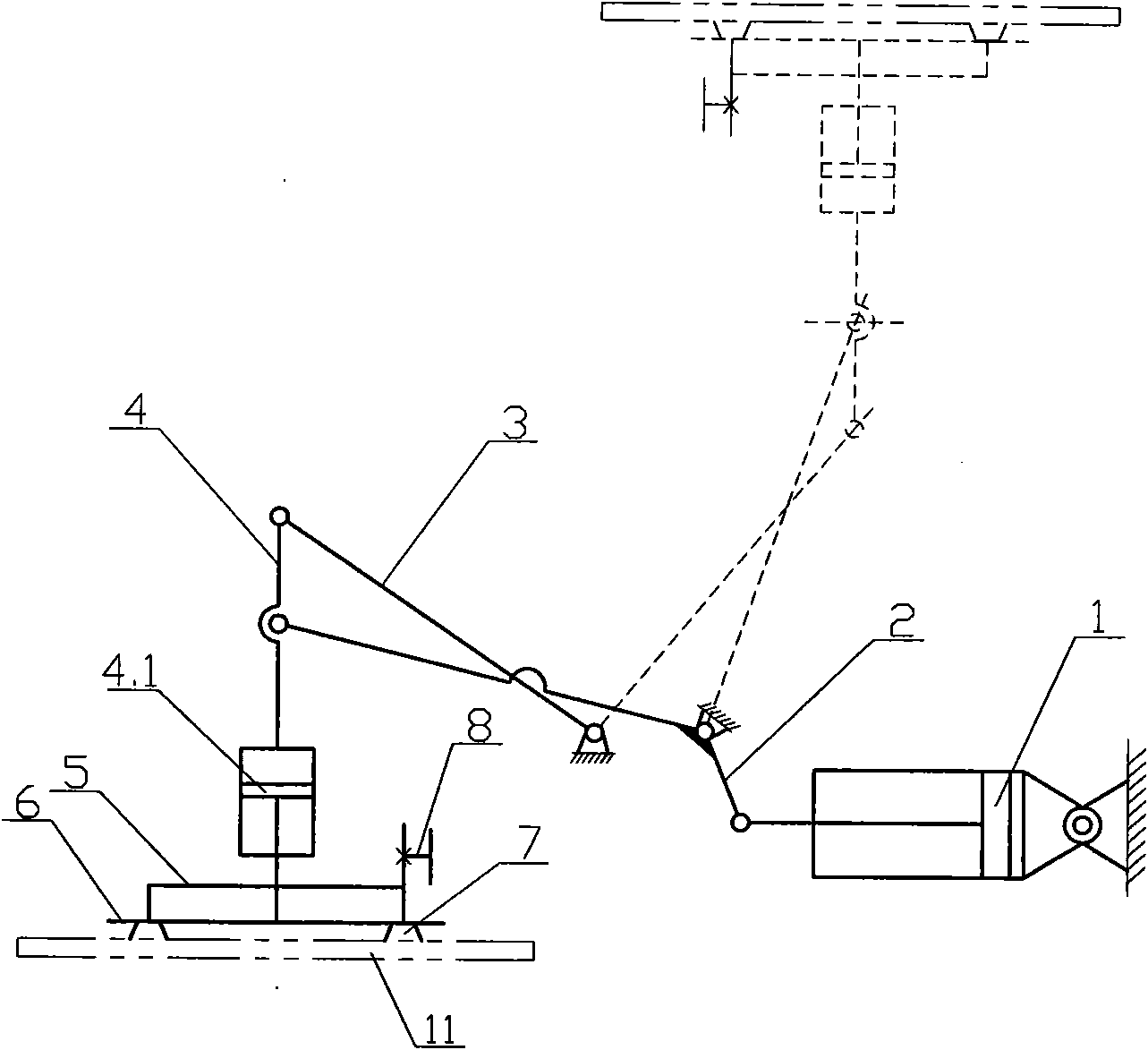

[0017] figure 1 The shown ceramic floor tile tiling device includes a turning mechanism installed on the vehicle frame, a lifting mechanism and a power system. Described vehicle frame comprises flat rectangular bottom plate 9 and the wheel 9.1 that is in rolling contact with the ground, and wheel 9.1 is universal wheel, and vehicle frame is equipped with universal wheel and can move in any direction. Base plate 9 top left ends in the vehicle frame correspond to crank 2, the positioning end of rocking bar 3 to be provided with the boss that is hinged; Turnover mechanism is main mechanism among the present invention, and it is the four-bar linkage mechanism that is driven by master cylinder 1. The overturning mechanism includes connecting rod 4, rocking rod 3 and crank 2. The connecting rod 4 is in a T-shaped structure. 2. The bottom end is hingedly connected with the piston rod of the main cylinder 1, and through the above-mentioned sequential connections, a turning mechanism...

Embodiment 2

[0020] The ceramic floor tile of present embodiment paving is 1200mm * 1200mm, and every piece weighs 48 kilograms. Due to the large area and heavy weight of the workpiece, the corresponding plate 6 was replaced under the condition that the device structure remained unchanged, and the matching suction cup 7 was adjusted to Φ150mm, a total of 9 pieces. Under this condition, the paving of super large ceramic floor tiles 11 is completely satisfied. Requirement, have the same technical effect with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com