Fuel gas mixing bag for producting energy saving lamp

An energy-saving lamp and gas technology, which is applied in the manufacture of ships or lead wires, etc., can solve the problems of scattered adjustment switches, easy formation of turbulent and eddy current dead angles, inconvenient operation, etc. The effect of the overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described with reference to the drawings and embodiments:

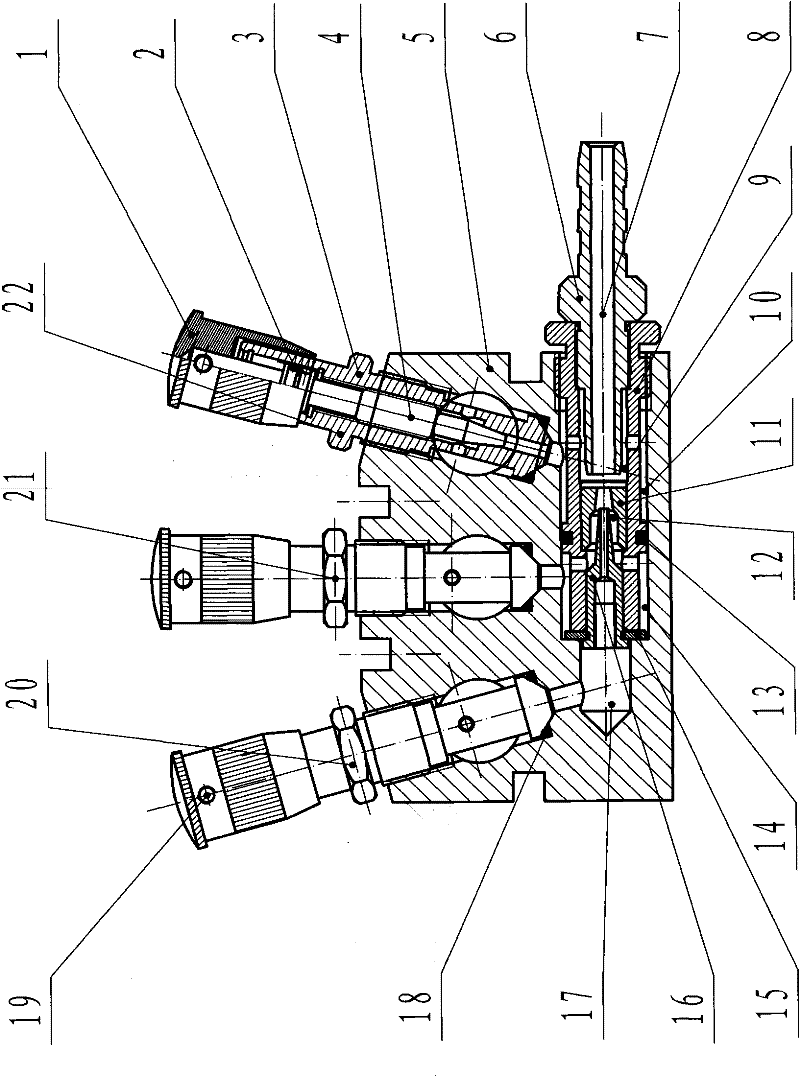

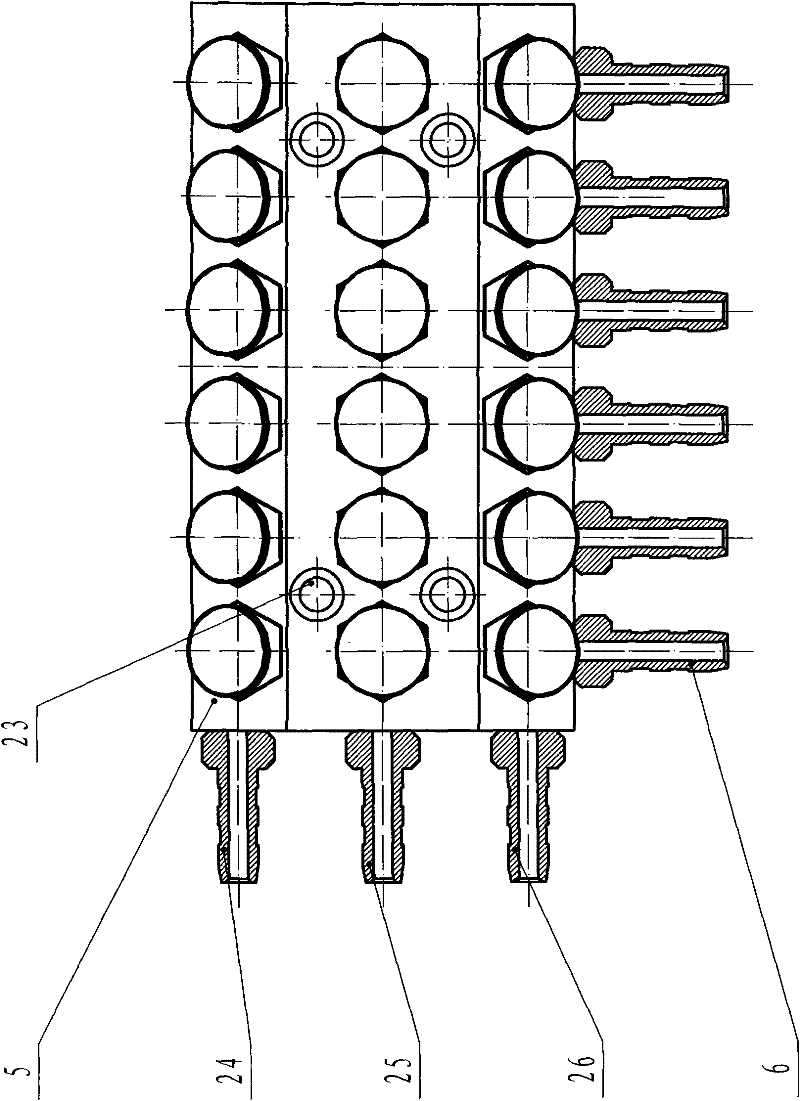

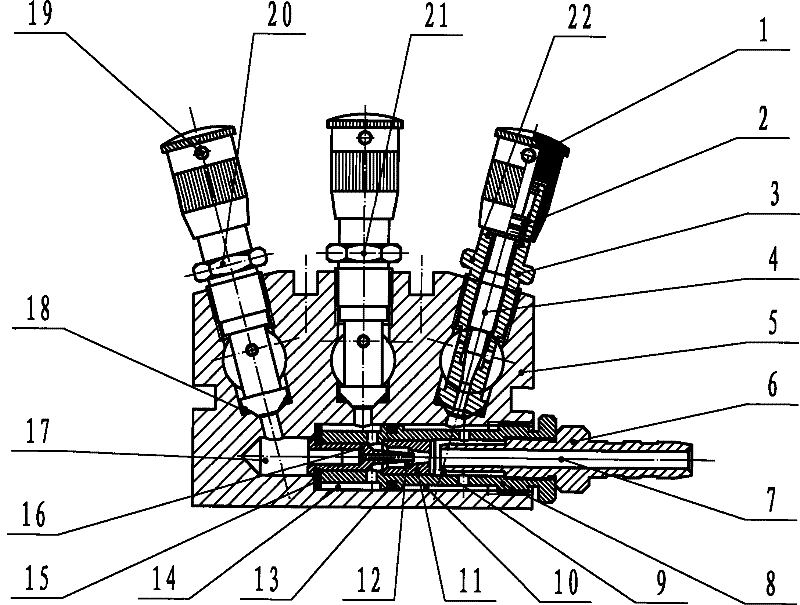

[0024] Such as figure 1 , figure 2 As shown, a gas mixing bag for the production of energy-saving lamps is mainly composed of a valve body 5, a regulating valve, and a gas mixing valve. The valve body 5 is provided with three independent main cavities. The independent main pipe cavity is connected to the oxygen source, compressed air source, and fuel gas source through the oxygen connector 24, compressed air connector 25, and gas connector 26 to form an independent oxygen main line, compressed air main line, and gas main line; There is a row of adjustment valves corresponding to the oxygen main line, compressed air main line, and gas main line. Each row of adjustment valves is an oxygen adjustment valve 20, a compressed air adjustment valve 21, and a gas adjustment valve 22; the oxygen adjustment valve 20, compression The air adjusting valve 21 and the gas adjusting valve 22 are all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com