Resonant tracking non-contact power supply device and power supply method

A non-contact power supply and tracking technology, which is applied in the direction of circuit devices, electrical components, electromagnetic wave systems, etc., can solve the problems of large-scale changes in the receiving end voltage, low coupling coefficient of the coupling channel, increasing the difficulty and cost of the design of the power supply circuit of the subsequent stage, etc. , to achieve the effect of reducing design difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment.

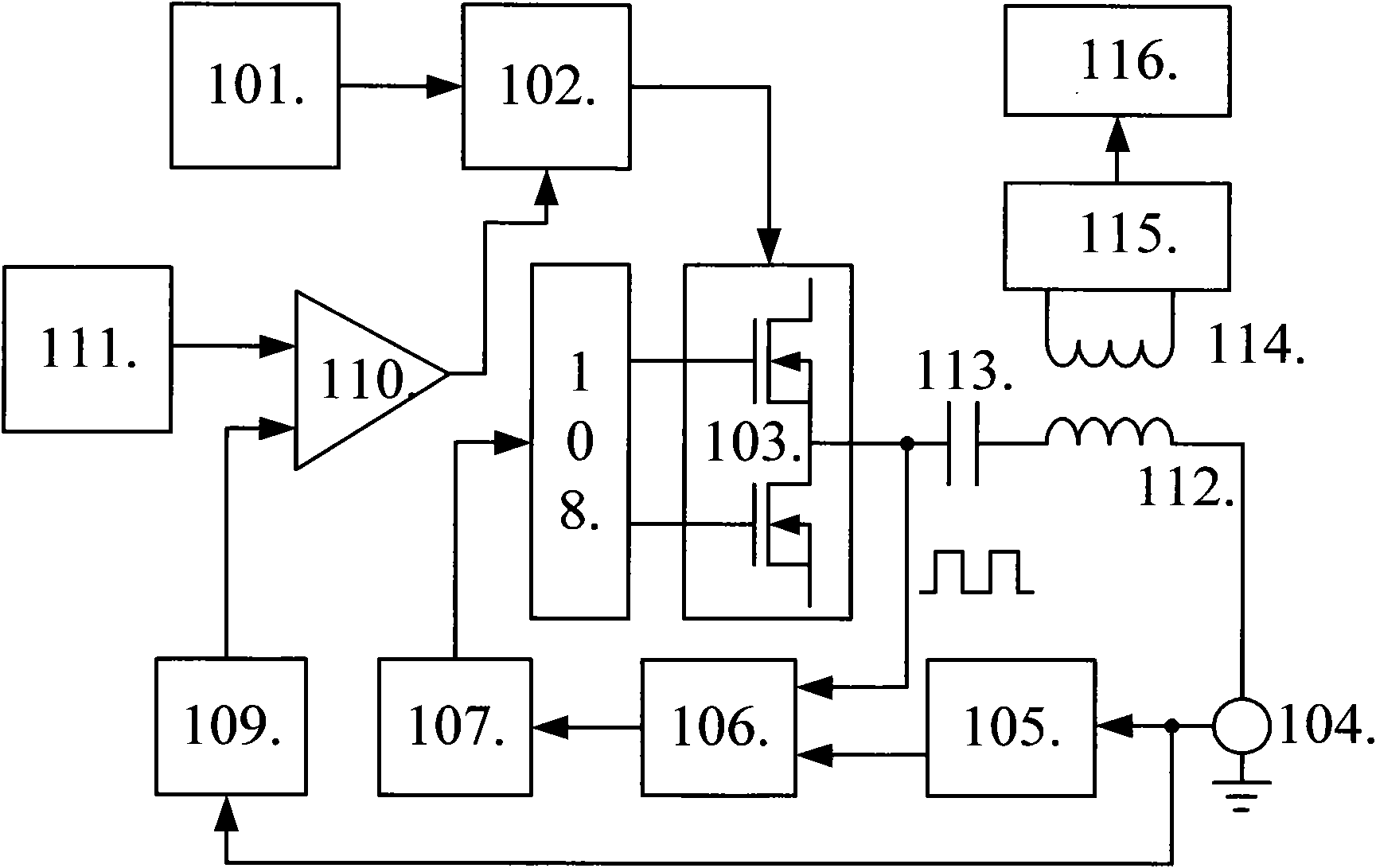

[0034] refer to figure 1Embodiment 1 of the present invention consists of a DC power supply 101, a switching power supply circuit 102, a MOS tube half-bridge switch 103, a current sampler 104, a zero-crossing comparator 105, a phase detector 106, a voltage-controlled oscillator 107, a floating gate driver 108, Detecting and filtering circuit 109 , error amplifier 110 , reference voltage 111 , power transmitting coil 112 , resonant capacitor 113 , power receiving coil 114 , rectifying and stabilizing circuit 115 , and load 116 . Among them, the switching power supply 102 adopts a synchronous step-down mode, and the amplitude is adjustable from 0 to 100%. Its input terminal is from the DC power supply 101, and its output is connected to the MOS tube half-bridge switch 103 to form a high-power excitation source; the MOS tube half-bridge switch 103 The output passes through the resonant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com