Optical lens, optical system unit and imaging apparatus

An optical lens and light incident technology, applied in the direction of optical components, optics, instruments, etc., can solve the problems of reduced UV resistance and useless light transmittance of optical lenses, achieve excellent optical properties, suppress the change of refractive index with temperature, The effect of high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] [thermoplastic polymer]

[0018] The thermoplastic polymer (thermoplastic resin) effectively used for producing the optical lens of the present invention has a functional group capable of forming any kind of chemical bond with inorganic fine particles at least one of the main chain end (polymer chain end) or side chain.

[0019] Preferred examples of such thermoplastic polymers include:

[0020] (1) A thermoplastic polymer having at least one functional group selected from the following functional groups in the side chain:

[0021] [chemical formula 1]

[0022]

[0023] [R 11 , R 12 , R 13 and R 14 Each of may be any of the following groups: a hydrogen atom, a substituted or unsubstituted alkyl group, a substituted or unsubstituted alkenyl group, a substituted or unsubstituted alkynyl group, or a substituted or unsubstituted aryl group] 、-SO 3 H, -OSO 3 H, -CO 2 H, and -Si(OR 15 ) m1 R 16 3-m1 [R 15 and R 16 Each of is a hydrogen atom, a substituted or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

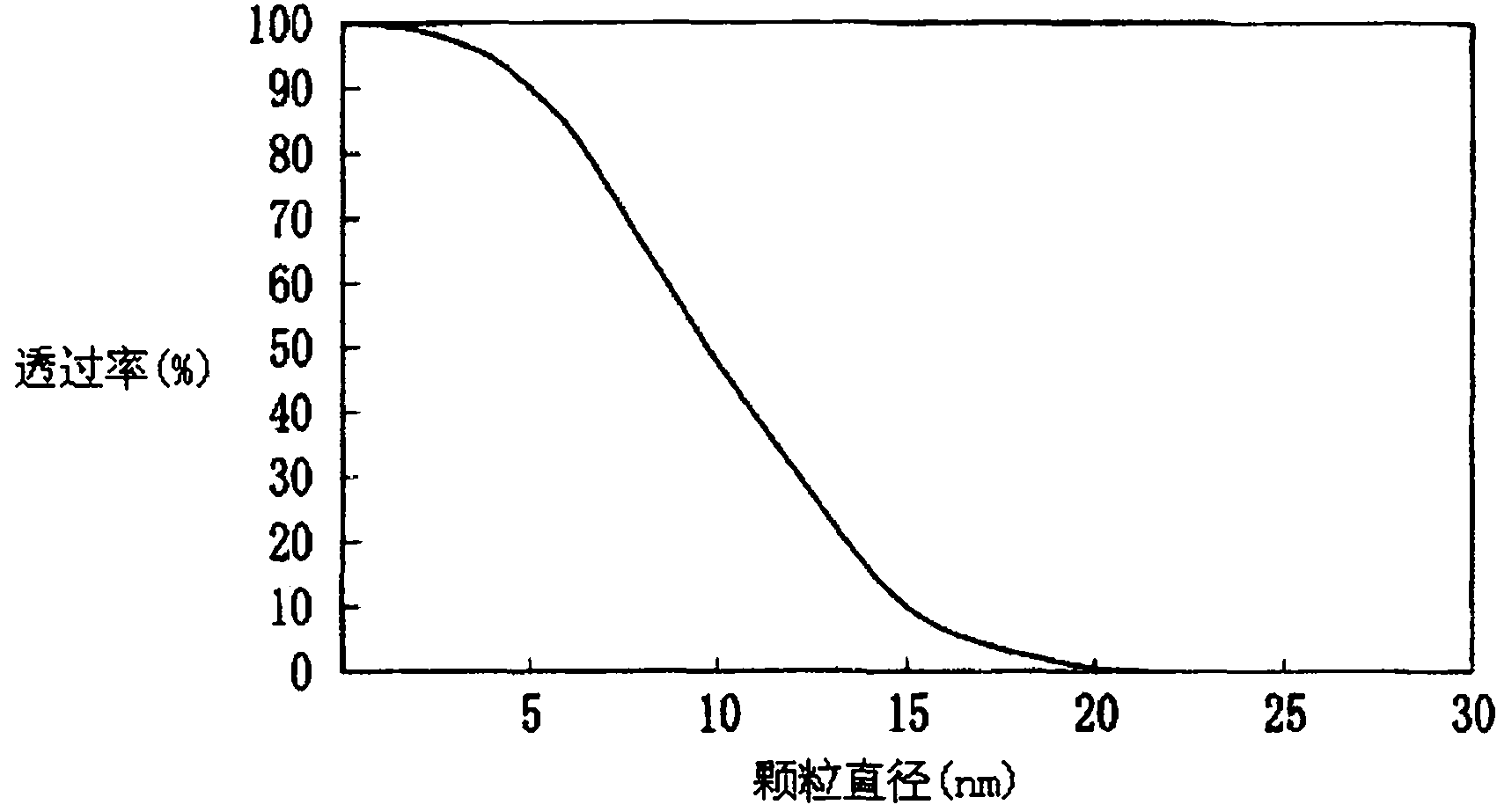

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com