Fluid catalytic conversion feeding preheating and reaction temperature control method

A technology of reaction temperature and fluidized catalysis, which is applied in catalytic cracking, chemical instruments and methods, and hydrocarbon production from oxygen-containing organic compounds, etc., can solve problems affecting reaction selectivity and conversion rate, unfavorable yield of light fractions, etc., to achieve The effect of flexible adjustment of reaction temperature, high energy utilization efficiency, and improvement of energy recovery rate and utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

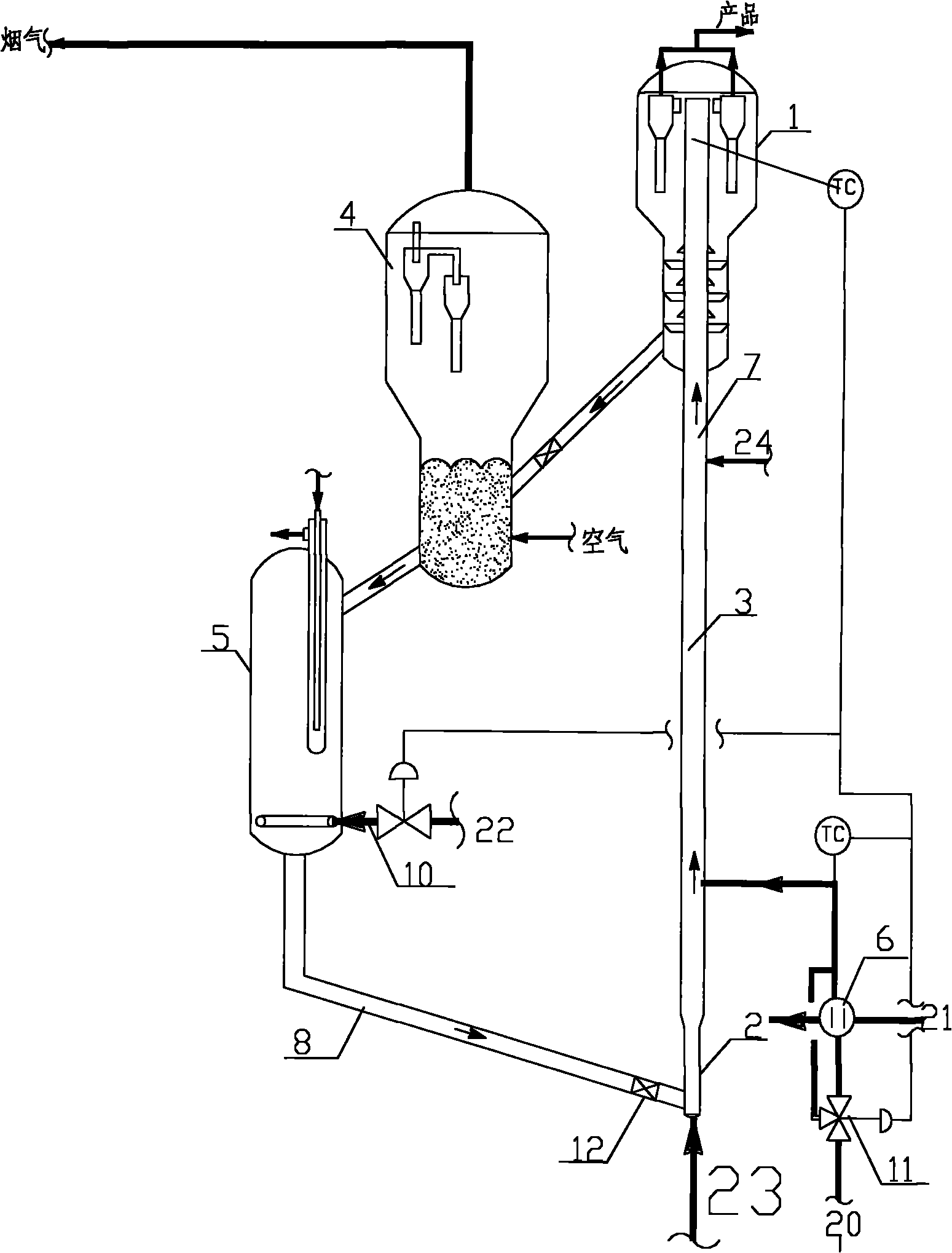

[0035] as attached figure 1 Shown: the catalytic conversion device adopting the method for feed preheating and reaction temperature control of the present invention includes a settler 1, and the riser reactor includes a pre-lift zone 2, a riser first reaction zone 3, and a second reaction zone 7 , regenerator 4, regenerated catalyst delivery pipe 8 (comprising control valve 12), regenerated catalyst cooler 5 and fluidized medium flow control valve 10 (for regulating the fluidized medium flow rate of regenerated catalyst cooler and then regulating the temperature of cold regenerated catalyst ), raw oil heater 6 and control valve 11 (for adjusting the bypass flow of raw oil and then adjusting the preheating temperature of raw oil).

[0036]The preheated heavy oil raw material 20 has a temperature of about 200-230°C. After being heated by the raw oil heater 6 of the present invention with the heating medium 21, it is mixed with the cold regenerated catalyst lifted and transported...

example 2

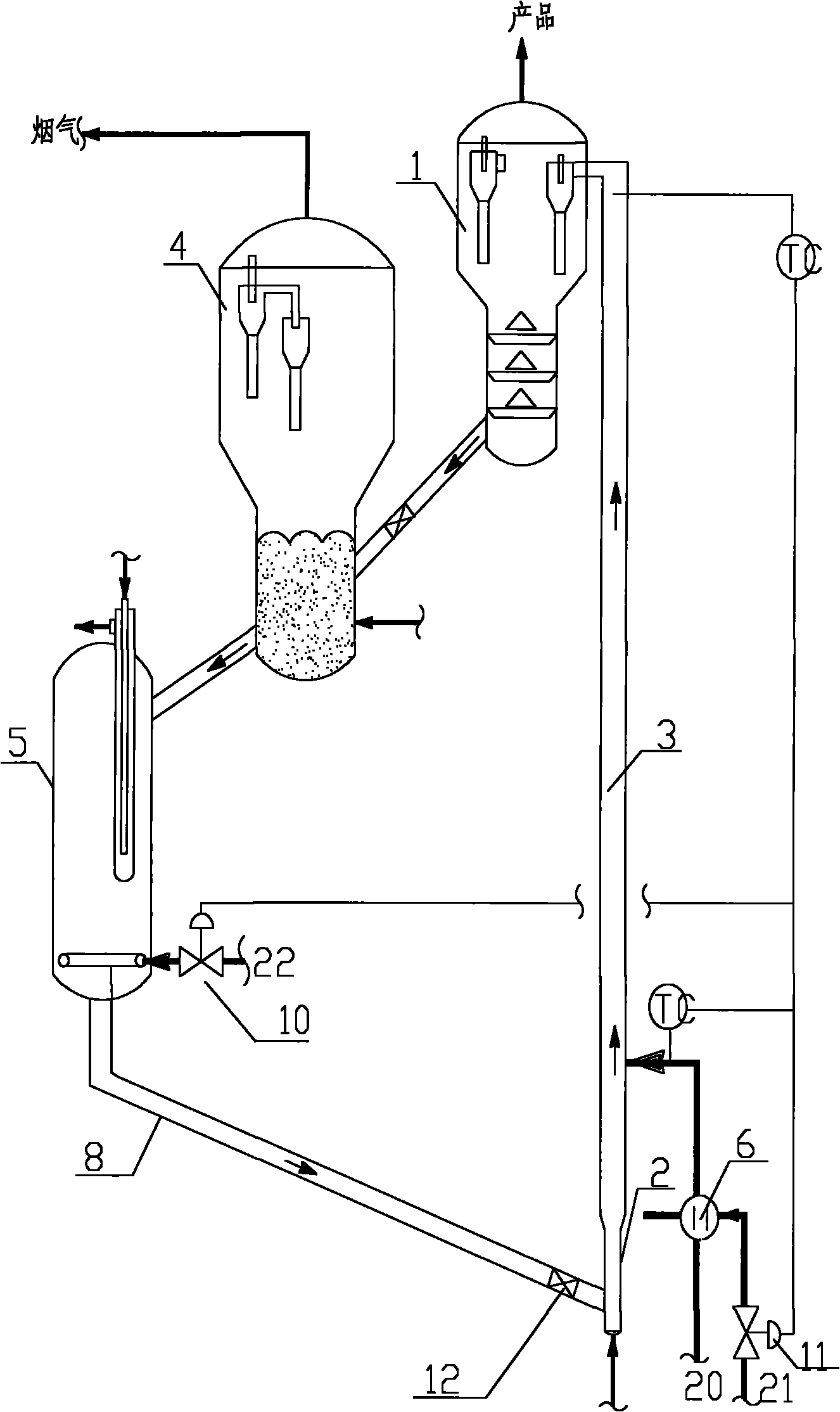

[0041] as attached figure 2 Shown: adopt the catalytic conversion device of the method for feed preheating and reaction temperature control of the present invention, comprise settler 1, riser reactor comprises pre-lift zone 2, riser reaction zone 3, regenerator 4, regenerated catalyst conveys Pipe 8 (including control valve 12), regenerated catalyst cooler 5 and fluidized medium flow control valve 10 (used to adjust the fluidized medium flow rate of regenerated catalyst cooler and then adjust the temperature of cold regenerated catalyst), raw oil heater 6 and Control valve 11 (for adjusting the bypass flow rate of heating medium 21 and then adjusting the preheating temperature of raw oil).

[0042] Unpreheated light hydrocarbon raw material (gasoline) 20 with a temperature of about 40° C., after being heated by the heating medium 21 of the feed oil heater 6 of the present invention, is mixed with the cold regenerated catalyst and enters the reaction zone 3 of the light hydroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com