Surface-treating liquid for conductive elastic layer, method of surface treatment of the same, and surface-treated conductive member

A technology of surface treatment liquid and conductivity, which is applied to the device for coating liquid on the surface, the electric recording process using the charge pattern, and the equipment for the electric recording process using the charge pattern, etc., which can solve the problems of durability deterioration, image deterioration, Solve problems such as adhesion, achieve the effect of improving voltage dependence and resistance variation, and preventing deterioration of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6、 comparative example 1~4

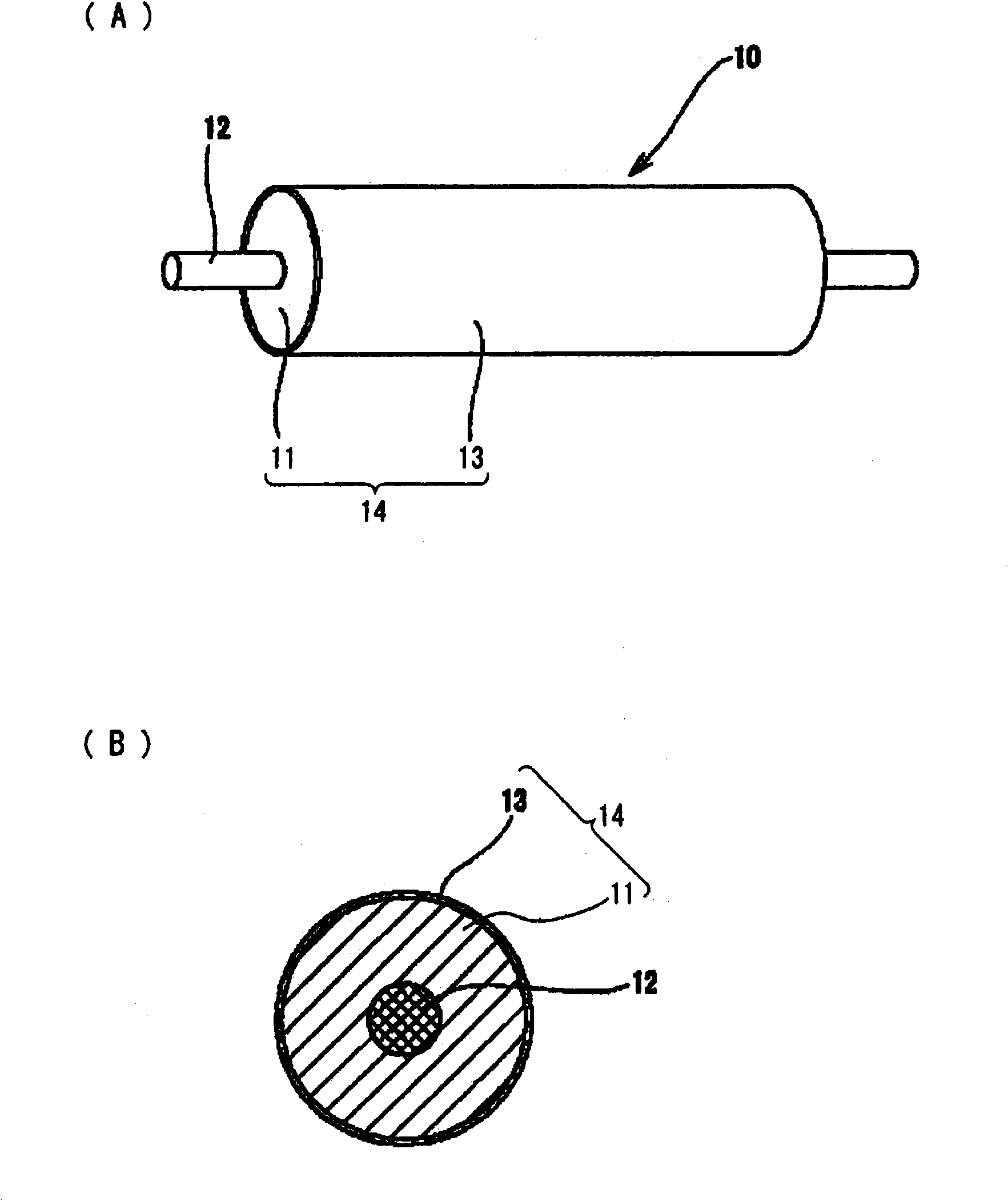

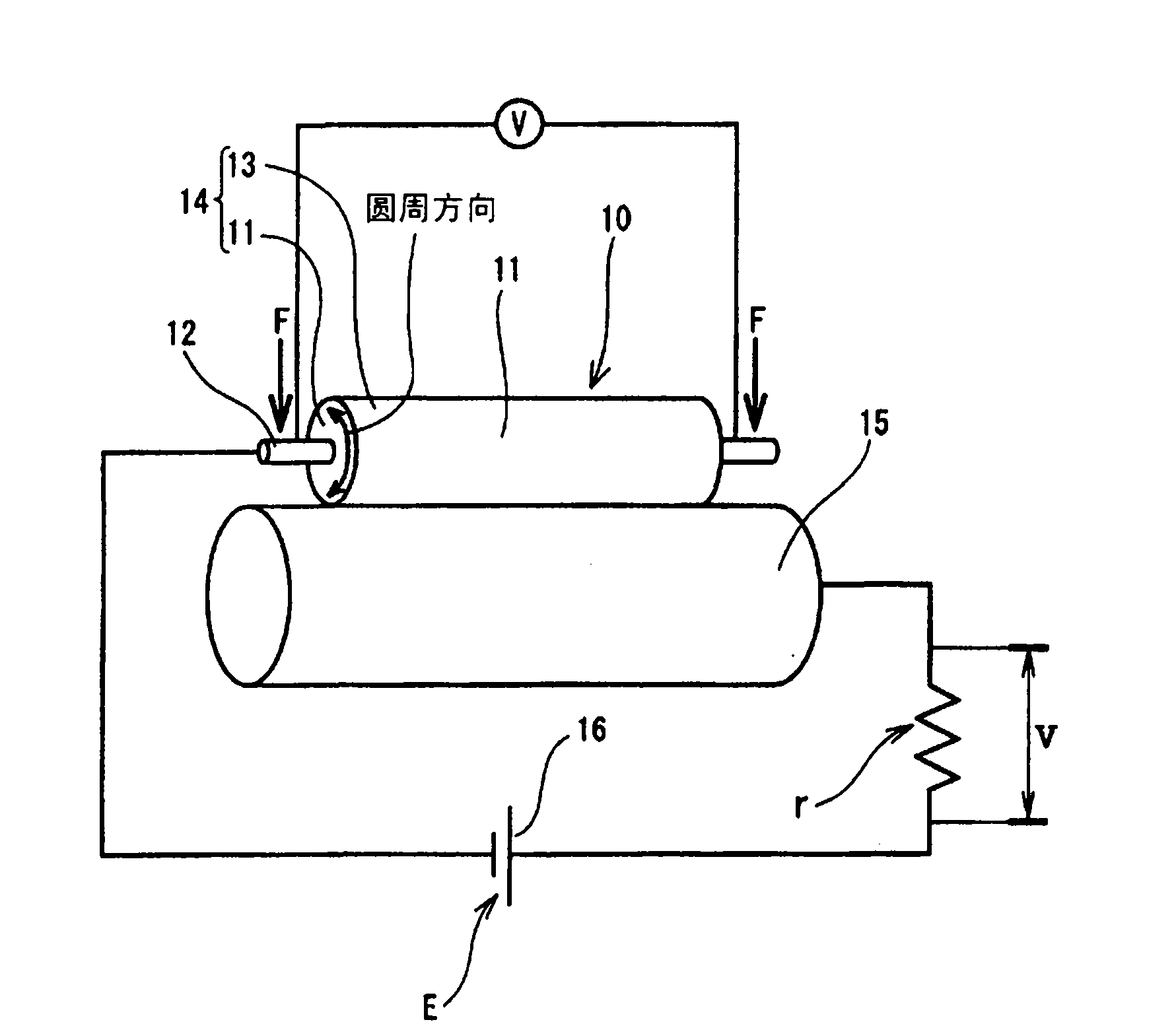

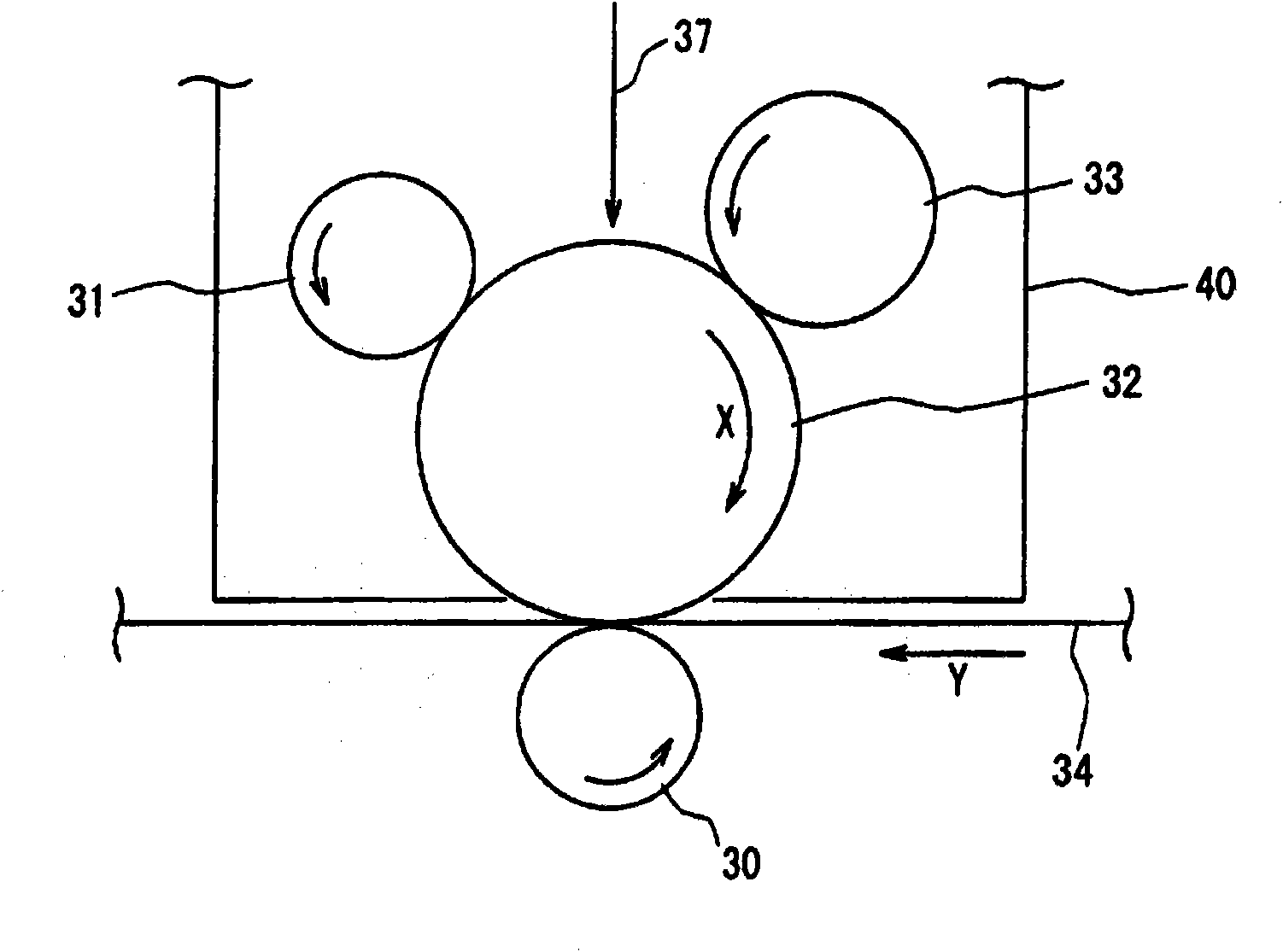

[0162] [Production of Conductive Roller with Conductive Elastic Layer]

[0163] Using the conductive thermoplastic elastomer composition according to the formulation described in Table 1, a tubular extruded product was produced, a mandrel (shaft) was inserted, and a conductive thermoplastic elastomer composition having a conductive elastic layer on a base material on which a coating layer was formed was produced. sex roll.

[0164] [Table 1]

[0165]

[0166] Specifically, the conductive roller was manufactured by the following method.

[0167] As the base polymer (A), a thermoplastic elastomer combination in which EPDM is dynamically crosslinked and dispersed with a resin crosslinking agent in a mixture of styrene-based thermoplastic elastomer (SEEPS) and polypropylene resin (PP) is used thing.

[0168] First, EPDM is granulated in advance, and the granulated EPDM, styrene-based thermoplastic elastomer (SEEPS), polypropylene resin (PP), crosslinking agent, and softener ar...

Embodiment 1~6

[0191] As the carbon nanotube dispersion (CNT dispersion), commercially available products shown below in which carbon nanotubes were previously dispersed in water were used.

[0192] When adding the main ingredient containing a polyisocyanate compound and water, the water and the main ingredient are mixed, then mixed with the additive, and then the CNT dispersion is added, stirred and mixed with a stirrer, and the surface treatment liquid is prepared.

Embodiment 7~11、 comparative example 5~8

[0255] [Production of Conductive Roller with Conductive Elastic Layer]

[0256] Using the conductive thermoplastic elastomer composition according to the formula described in Table 4, a tubular extruded product was produced, a mandrel (shaft) was inserted, and a conductive thermoplastic elastomer composition having a conductive elastic layer on a base material on which a coating layer was formed was produced. sex roll.

[0257] [Table 4]

[0258]

Element

Recipe amount

(parts by mass)

EPDM

100

SEEPS

24.69

PP

10

crosslinking agent

12

softener

174

[0259]

Element

Recipe amount

(parts by mass)

30

10

Compatibilizer

6

conductive agent

60

TPEE

50

[0260] The manufacturing method and the components used for the conductive roller 11 are the same as those of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com