Dye-sensitized solar cell module

A technology for solar cells and dye sensitization, applied in the field of solar cell modules, can solve the problem that dye-sensitized solar cells cannot be used as they are, and achieve the effects of reliable electrical connection, excellent manufacturing performance and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

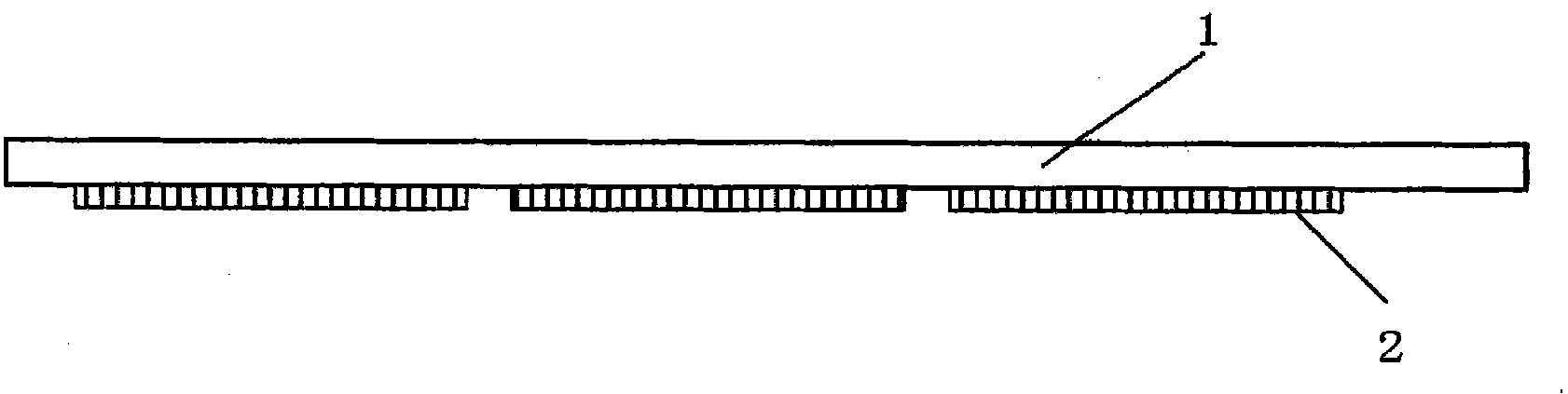

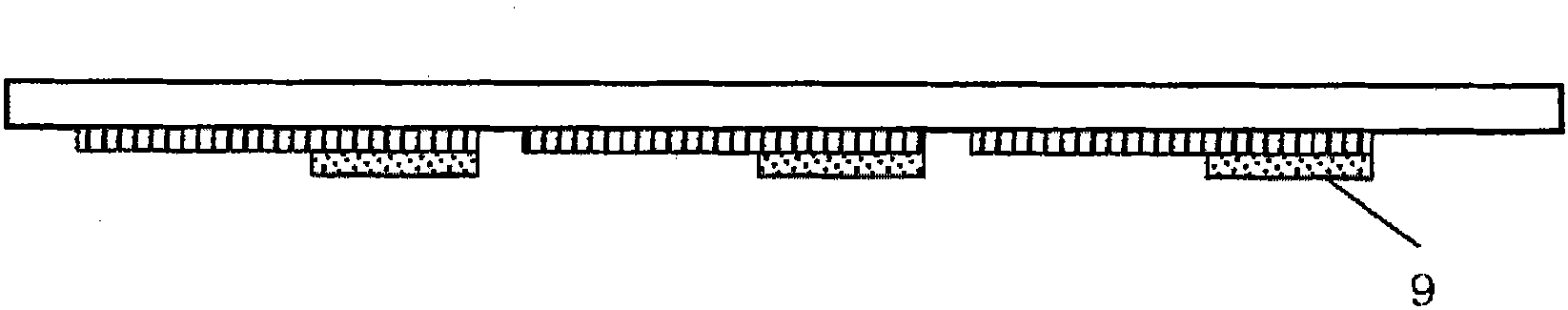

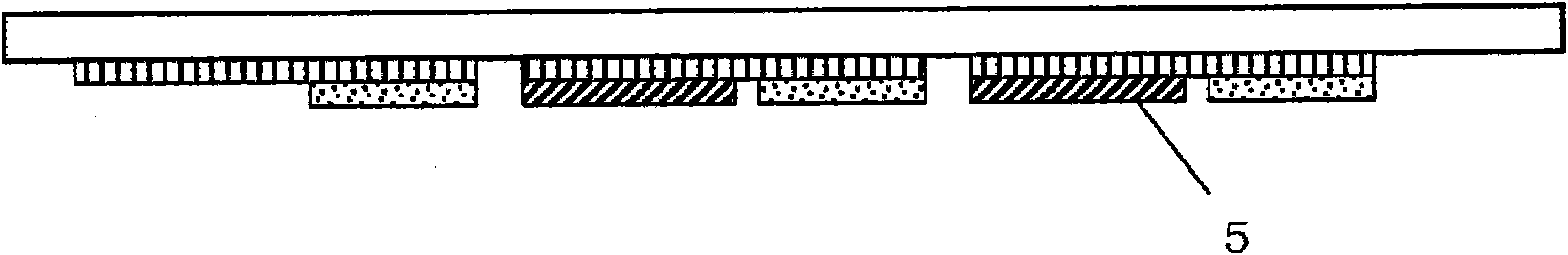

[0136] Such as figure 1 As shown, three rows of FTO thin films as conductive substances were formed on a glass plate with a thickness of 1.1 mm as a first substrate by CVD, thereby forming a first conductive layer. Subsequently, the TiO 2 Paste of particles (particle size 20nm) and terpineol (terpineol: TiO 2 The mass ratio of the particles is 70:30) coated on the first conductive layer, and baked at 450 ° C for 30 minutes to form a semiconductor-containing layer (film thickness 15 μm, short axis width 5 mm) ( figure 2 ). Silver paste Varniphite M-18 (trade name of silver paste manufactured by Nippon Black Lead Industry Co., Ltd.) was applied to the semiconductor-containing layer by screen printing, and dried at 120° C. for 30 minutes to form a third conductive layer (film Thickness 8~15μm, some bumps)( image 3 ).

[0137] Next, the first substrate provided with the semiconductor-containing layer obtained as described above was immersed in the solution for 36 hours at ...

Embodiment 2

[0147] Except for arranging six rows of cells in series, the dye-sensitized solar cell module (module C) of the present invention was manufactured in the same manner as in Example 1 ( Figure 12 ).

Embodiment 3

[0149] Except that the third conductive layer was provided only on the first substrate, the dye-sensitized solar cell module (module D) of the present invention was manufactured in the same manner as in Example 2 ( Figure 13 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com