Energy-storage type energy-saving heater and processing method thereof

A heater and energy storage technology, which is applied in the heating device and other directions, can solve the problems of incomplete bonding between the inner pot and the metal surface, large energy consumption, energy waste, etc., and achieve good heat release effect, good heat storage, Fast heat absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

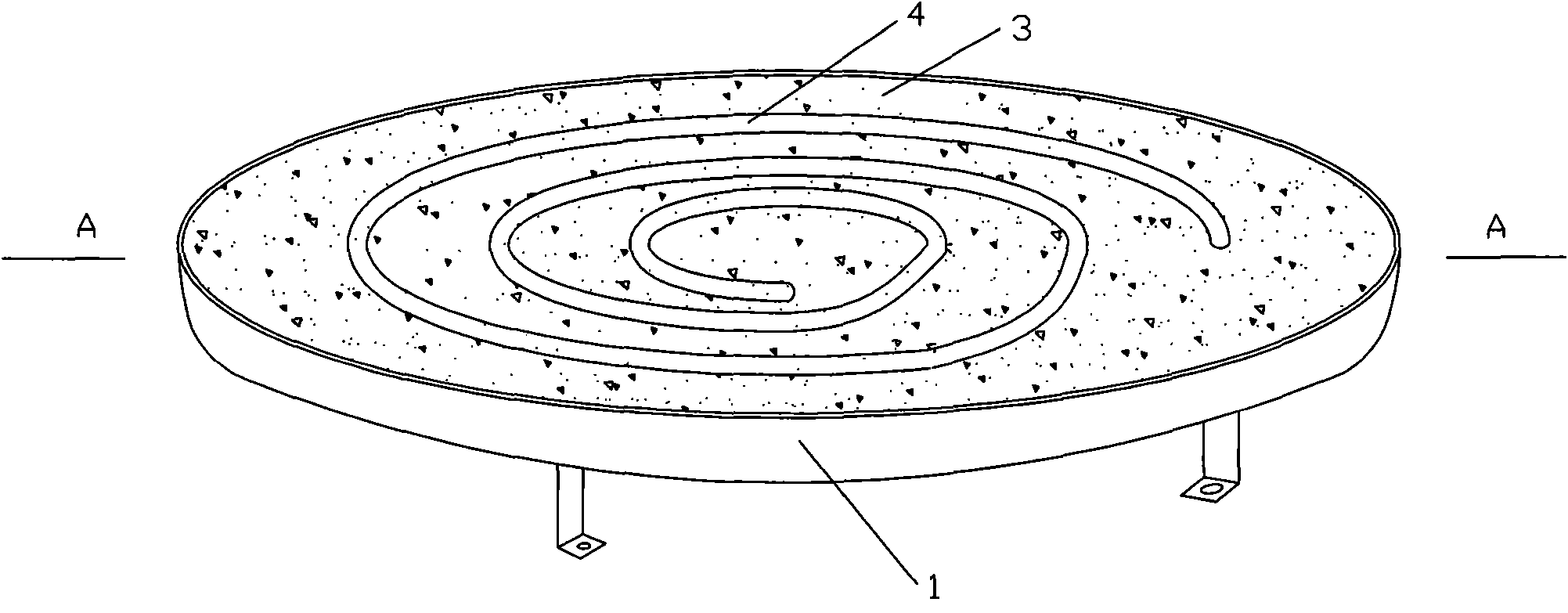

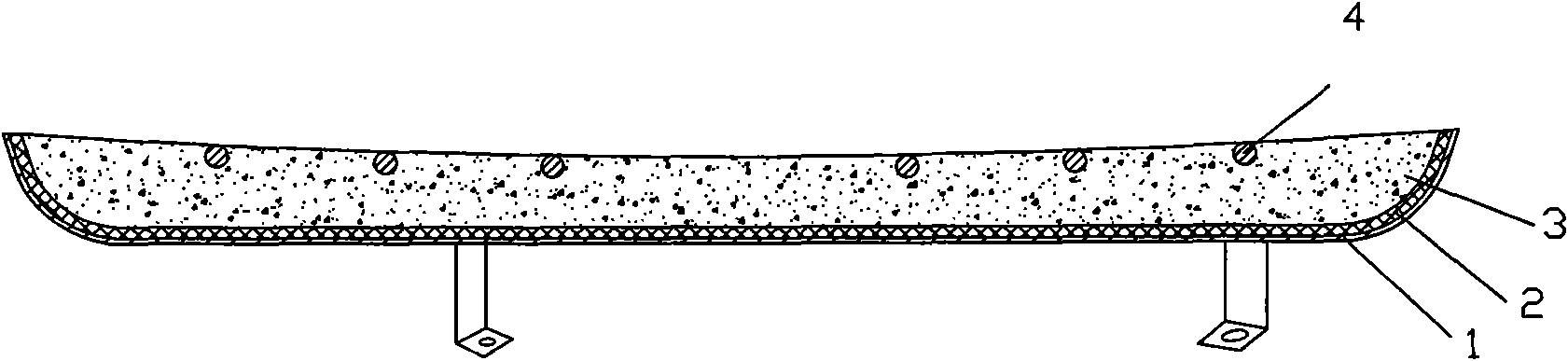

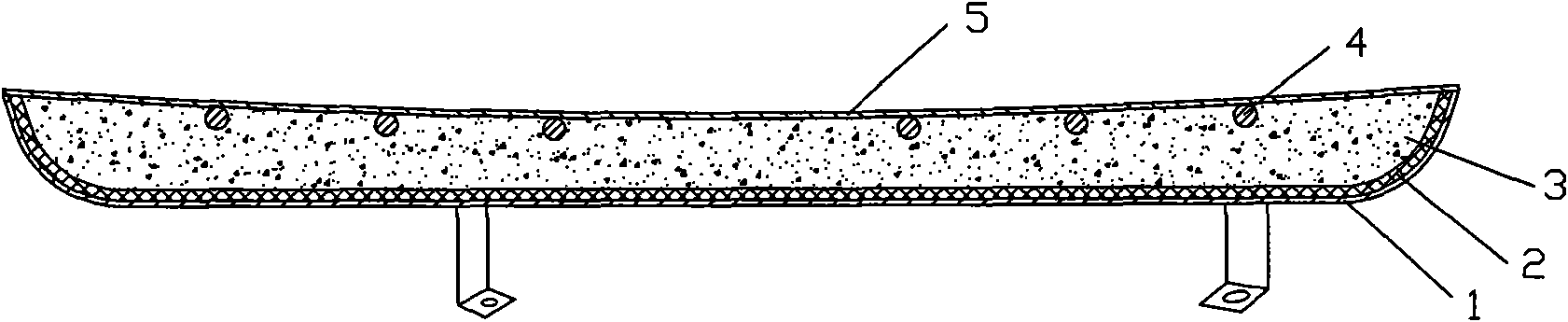

[0022] figure 1 , 2 As shown in and 3, the energy storage type energy-saving heating device of the present invention comprises a bottom shell 1, a thermal insulation layer 2, a thermal storage layer 3 and a heating wire 4, the thermal insulation layer 3 is arranged on the bottom casing 1, and the thermal storage layer 3 is located on the On the top of the heat insulation layer 2 , the heating wire 4 is arranged on the top of the heat storage layer 3 . The heating wire 4 is in the shape of a spiral, and the surface of the spiral disk is a concave structure, and the surface of the concave spiral disk is heated to form a flat surface, which is always kept in contact with the inner pot, and is evenly heated and energy-saving. Between the heating wires 4 Heat storage filling materials are arranged between the heating wire 4 and the side wall of the bottom case 1 . The material of the above-mentioned heat storage layer 3 is alxite, and the material of the thermal insulation layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com