Bucket rod slot plate forming method of 6-ton digging machine

A forming method and excavator technology, which is applied in the field of processing bending parts of construction machinery, can solve problems such as dimensional errors, inability to guarantee weld quality requirements, and affect the quality of sticks, and achieve the effect of accurate dimensions and meeting welding quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

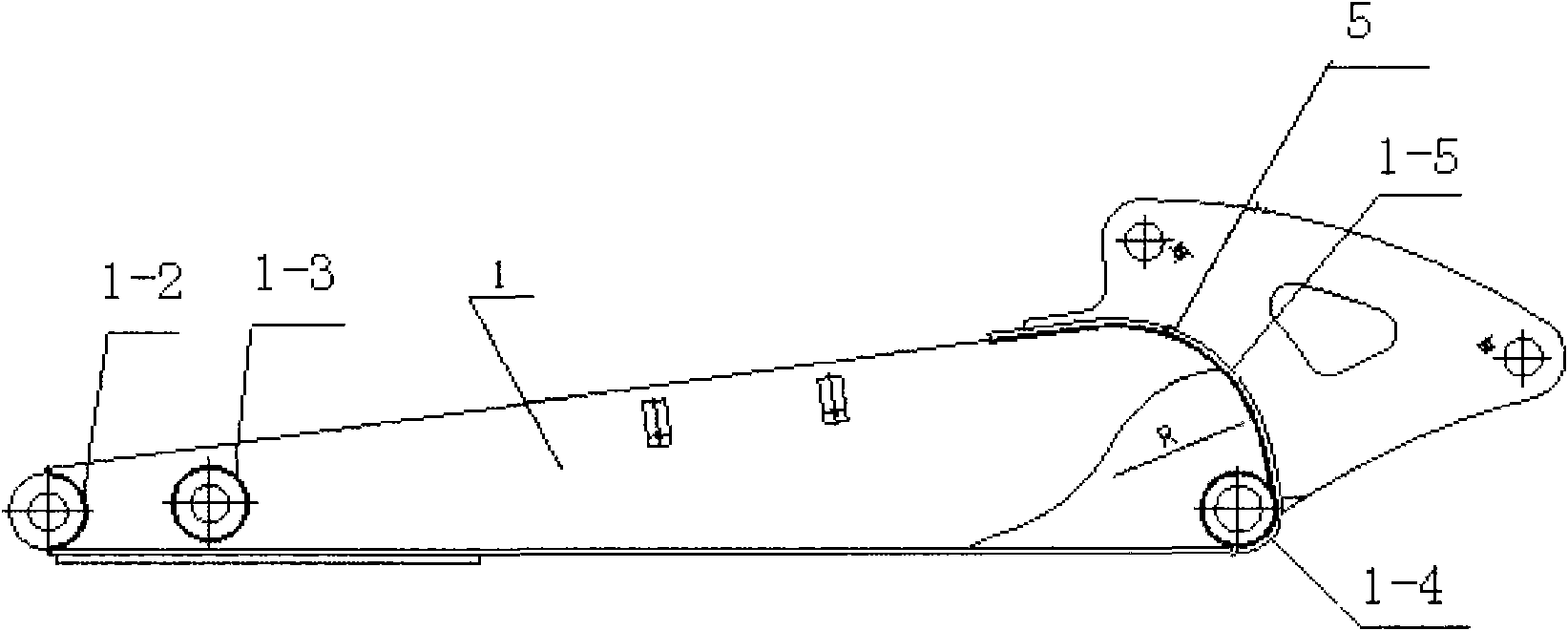

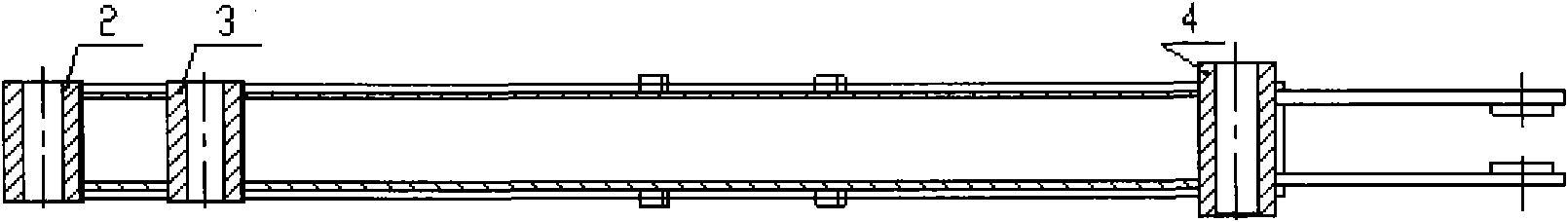

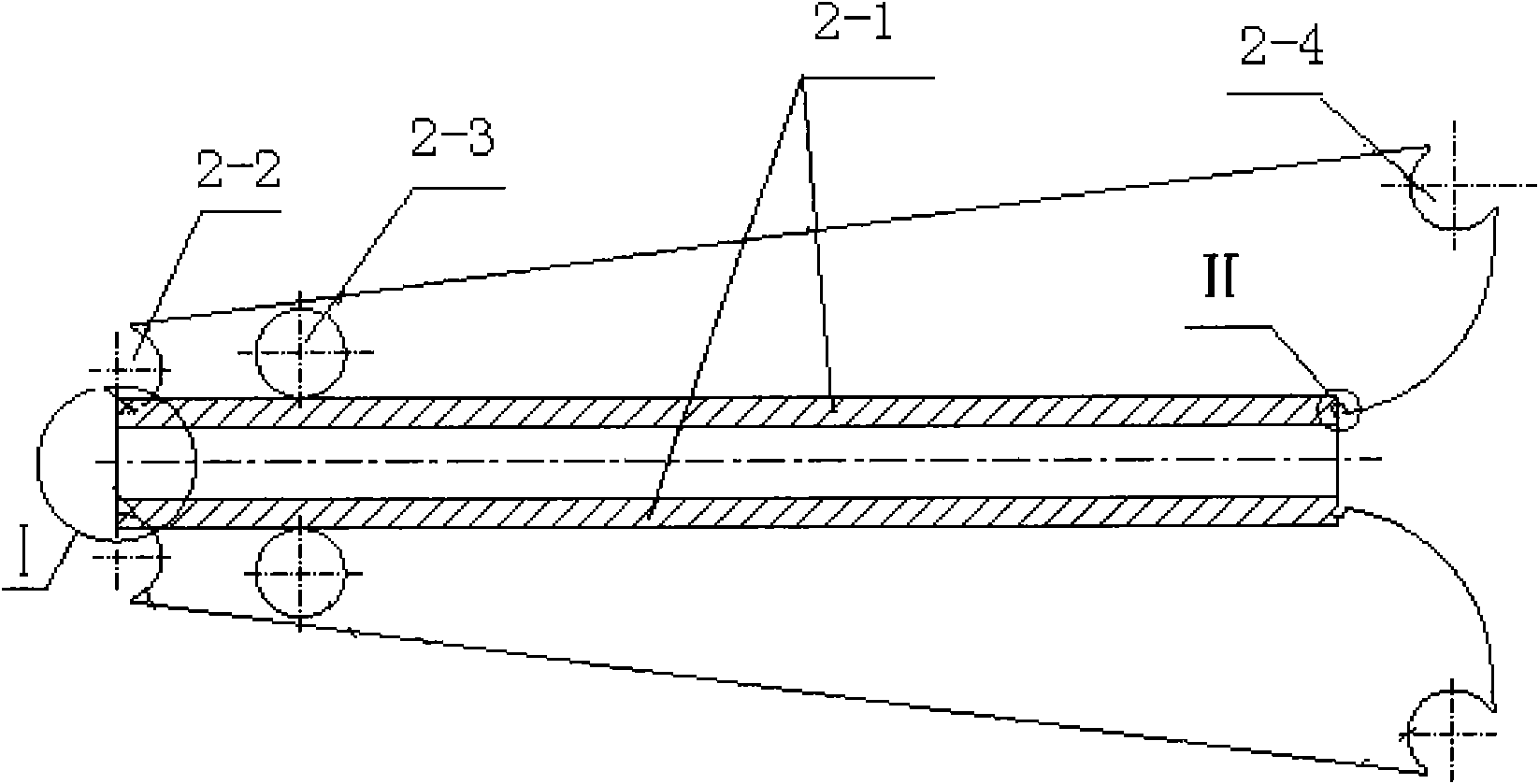

[0025] A method for forming a 6-ton excavator arm groove plate provided by the invention, the steps are:

[0026] Step 1. The bending part is extended due to the compression of the plate during the pressing process. The extension length is affected by the different materials, the size of the R angle of the pressing and the thickness of the plate. The unfolded length of the bending part must be determined according to the actual situation. According to item 6 of JB / T5109-2001 sheet metal bending process design specification standard document, the present invention calculates the bending expansion length l of the arm groove plate 1, and the steps are roughly as follows:

[0027] Step 1.1. Take the value of the displacement coefficient x of the neutral layer. In this embodiment, according to r / t=1.33, take bending radius r=8mm, plate thickness t=6mm, neutral layer displacement coefficient x=0.34;

[0028] Step 1.2, according to the above value, determine the neutral layer radius...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that in Step 4, the center position of the arc R of the arm groove plate 1 needs to be moved downward by an amount K=1.5 mm. In step 5, the width b of the transverse relief groove is 4 mm, and the length c is 4 mm. Other steps are identical with embodiment 1.

Embodiment 3

[0039] The difference between this embodiment and embodiment 1 is that in step 4, the center position of the arc R of the arm groove plate 1 needs to be moved down by K=2mm. In step 5, the width b of the transverse relief groove is 7 mm, and the length c is 7 mm. Other steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com