Aeration rotary brush

An aeration brush and blade technology, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc. High power needs and other issues, to achieve the effect of improving oxygenation power efficiency and oxygenation capacity, improving oxygenation power efficiency, and improving oxygenation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

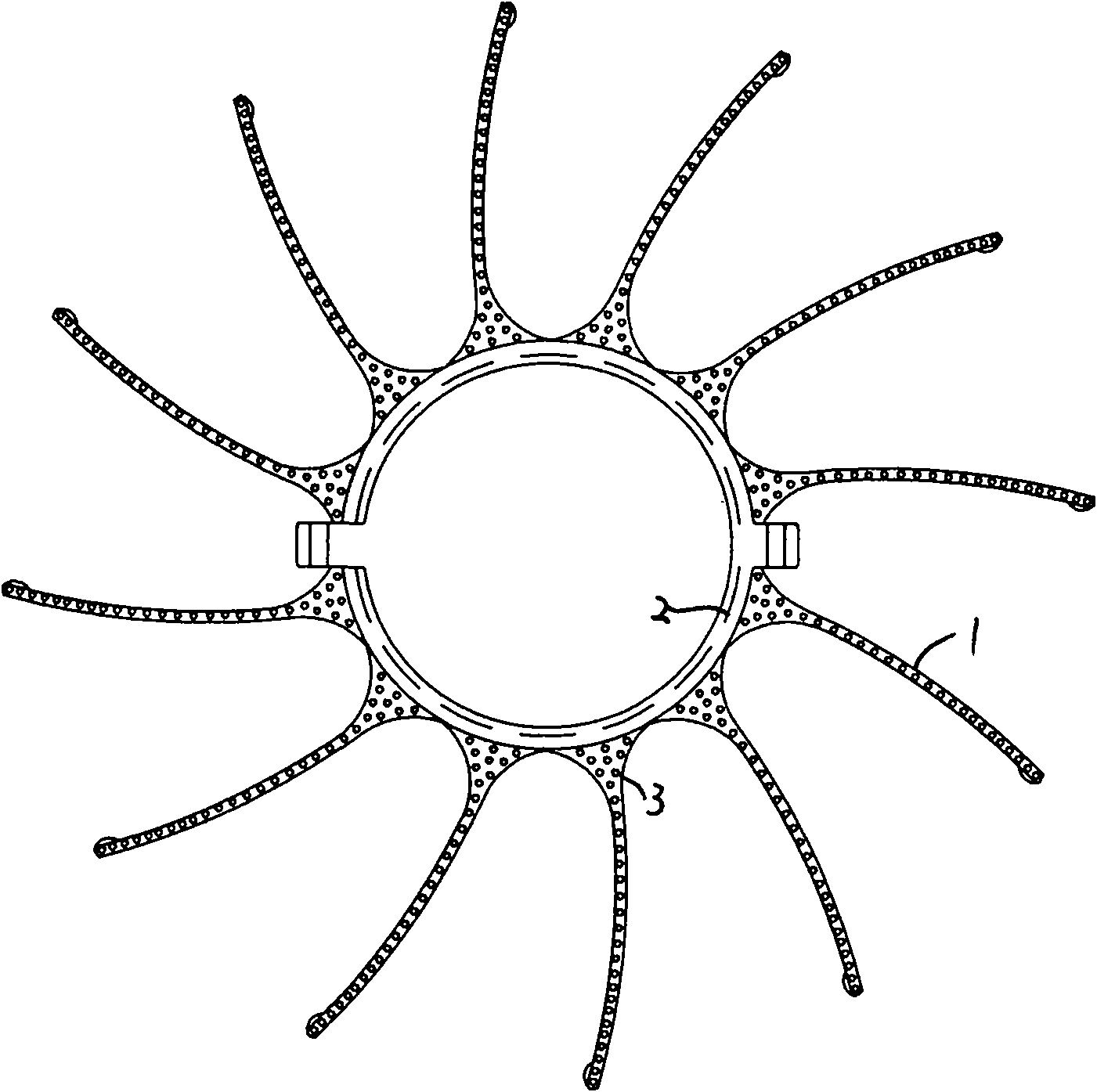

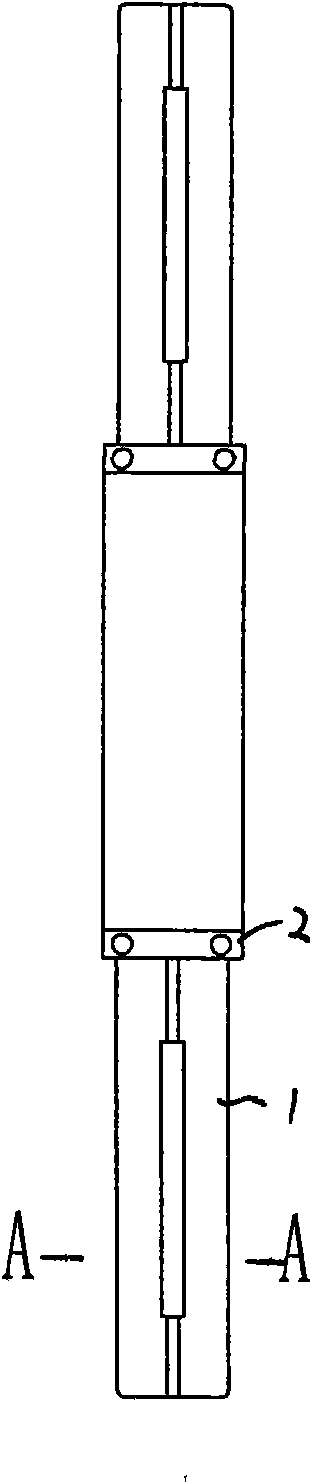

[0027] Example 1: see figure 1 , 2 , The aeration rotary brush of the present invention is composed of glass fiber reinforced resin molded into two symmetrical pairs. The rotating brush blade 1 is in a curved arc shape, and is integrally connected with a threaded hub sleeve 2, and each blade has pits 3 on both sides. During aeration operation, the curved convex surface is transferred into the water.

Embodiment 2

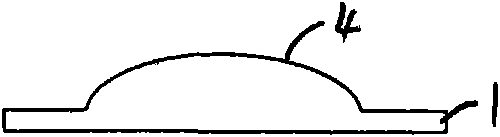

[0028] Example 2: see image 3 , As in the first embodiment, the surface (arc convex surface) of the rotating brush blade that is turned into the water surface has arc-shaped convex reinforcement ribs 4.

Embodiment 3

[0029] Example 3: See Figure 4 , As in Example 1, the turning brush blades into the water surface (arc-shaped convex surface) have concave arc-shaped convex reinforcement ribs 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com