Preparation method of modified polymer substrate solid dye laser medium

A laser medium and polymer technology, applied in the fields of organic dyes, chemical instruments and methods, luminescent materials, etc., can solve the problems of poor photostability and short lifespan of liquid dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

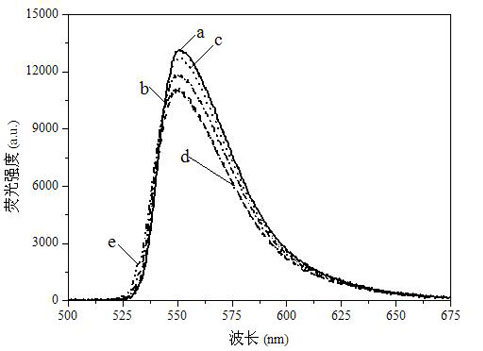

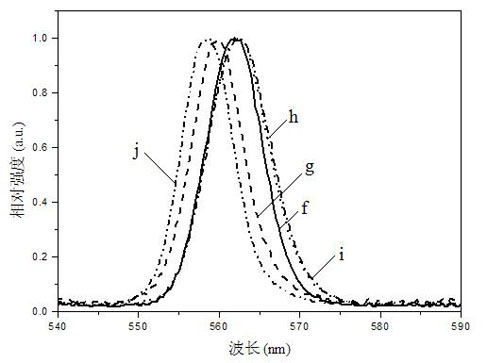

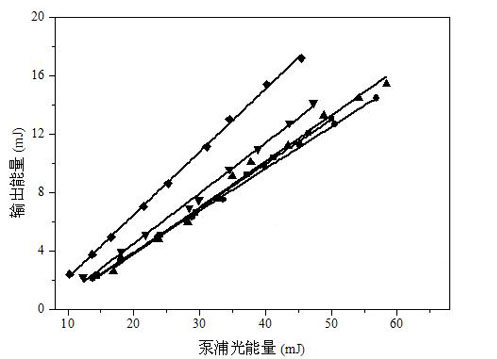

Image

Examples

specific Embodiment approach 1

[0009] Embodiment 1: The preparation method of the modified polymer matrix solid dye laser medium in this embodiment is as follows: 1. First, wash the methyl methacrylate three times with a NaOH solution with a mass concentration of 5% to 10%, and then wash it with distilled water Methyl methacrylate until the washing liquid is neutral, then carry out vacuum distillation of methyl methacrylate; 2. Methyl methacrylate and hydroxyethyl methacrylate treated in step 1 are mixed according to the ratio of 1.5 to 9:1 The volume ratio is mixed to obtain mixture A, then add ethanol to mixture A, and ultrasonically stir for 15min to 30min to obtain mixture B, the volume percentage concentration of ethanol in mixture B is 10% to 20%; 3. Add PM567 dye to mixture B , and then ultrasonically stirred for 10min to 15min to obtain a PM567 dye concentration of 2×10 -4 mol / L mixture C, add azobisisobutyronitrile to mixture C, and then continue ultrasonic stirring for 10min to 15min to obtain mix...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass concentration of the NaOH solution in Step 1 is 8%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, methyl methacrylate and hydroxyethyl methacrylate are mixed at a volume ratio of 2-8.5:1 to obtain mixture A. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com