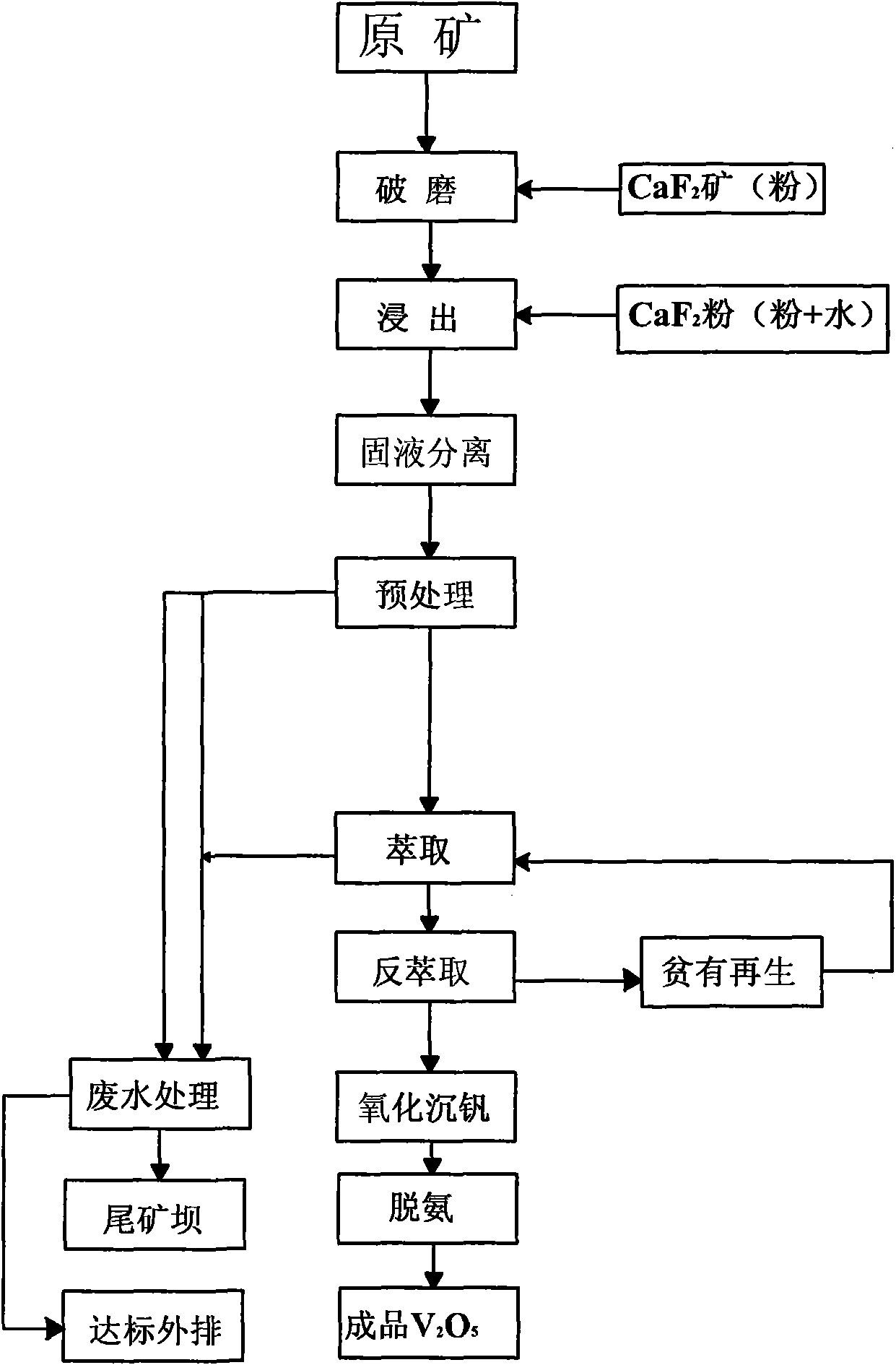

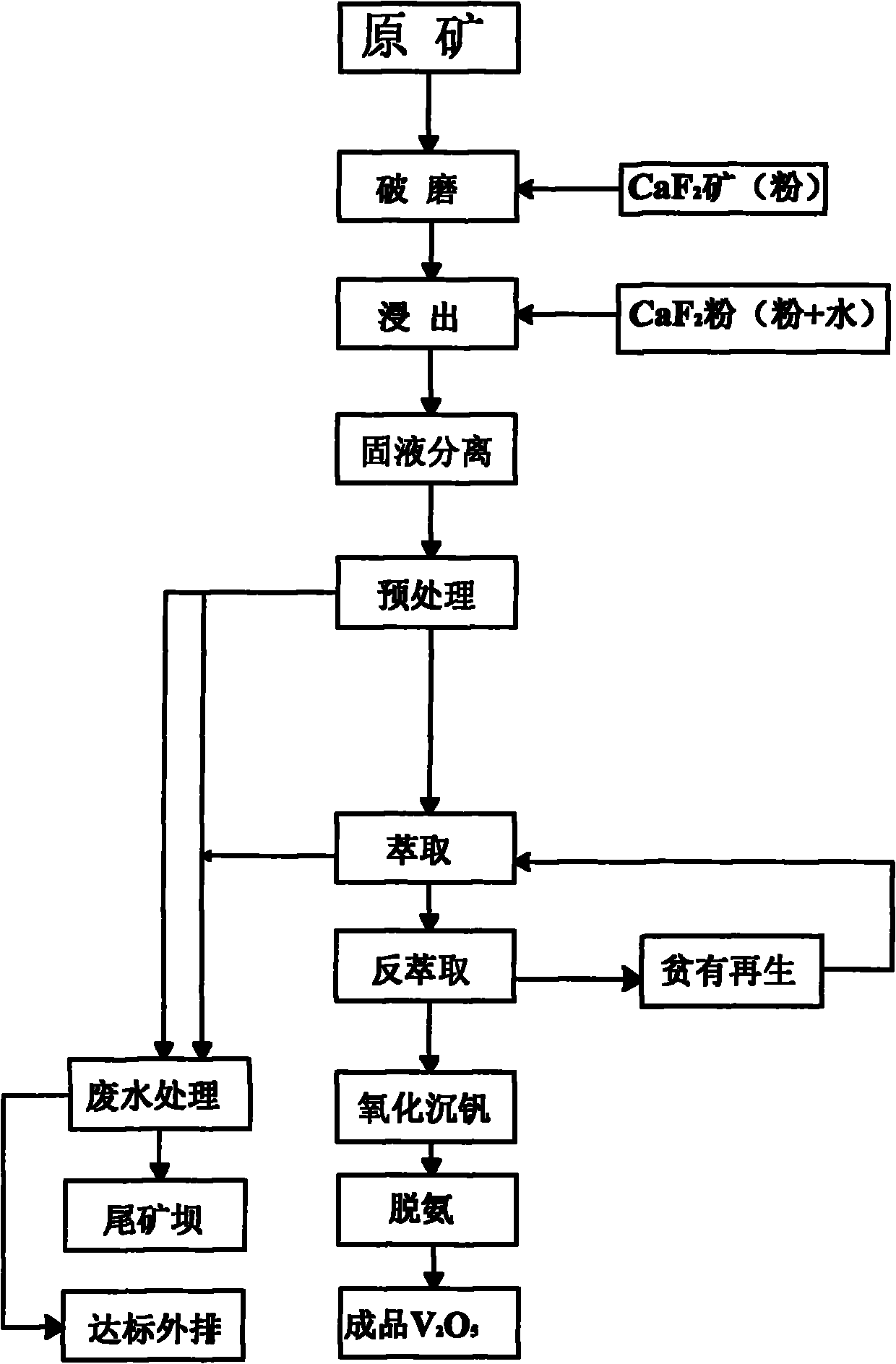

Process for extracting vanadium from stone coal by acid method by using leaching agent

A technology of leaching aid and stone coal acid, which is applied in the field of vanadium extraction by stone coal acid method, can solve the problems of low total recovery rate and low leaching rate, and achieve the effects of increasing economic benefits, reducing costs, and overcoming low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Compared with the hydrometallurgical process of other elements, the total recovery rate of vanadium in the existing stone coal acid vanadium extraction process is still low. The root cause is that the leaching rate cannot be improved. There are many reasons, among which, in addition to low-valence vanadium (V +2 , V +3 ) is generally mostly in the majority, and it is also closely related to its occurrence state. Most of the vanadium in stone coal is isomorphic. On the contrary, there are very few vanadium in the adsorption state. It is very difficult to destroy this structure, resulting in the leaching rate. Low.

[0022] The principle of the present invention is to use a small amount of cheap CaF 2 added to the leaching process to achieve a small amount of H 2 SO 4 In exchange for a small amount of HF, in order to destroy its structure and achieve the effect of increasing the leaching rate, a small amount of CaF 2 Joining is not only low cost, but also ensures tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com