Efficient heat transfer tube of heat exchanger for recycling smoke waste heat

A flue gas waste heat and heat transfer tube technology, applied in heat exchange equipment, tubular elements, lighting and heating equipment, etc., can solve the problems of wear and corrosion, reduce the life of heat exchangers, and dust accumulation, so as to prevent dust accumulation and Wear and improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The substantive content of the present invention will be further described below with examples in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

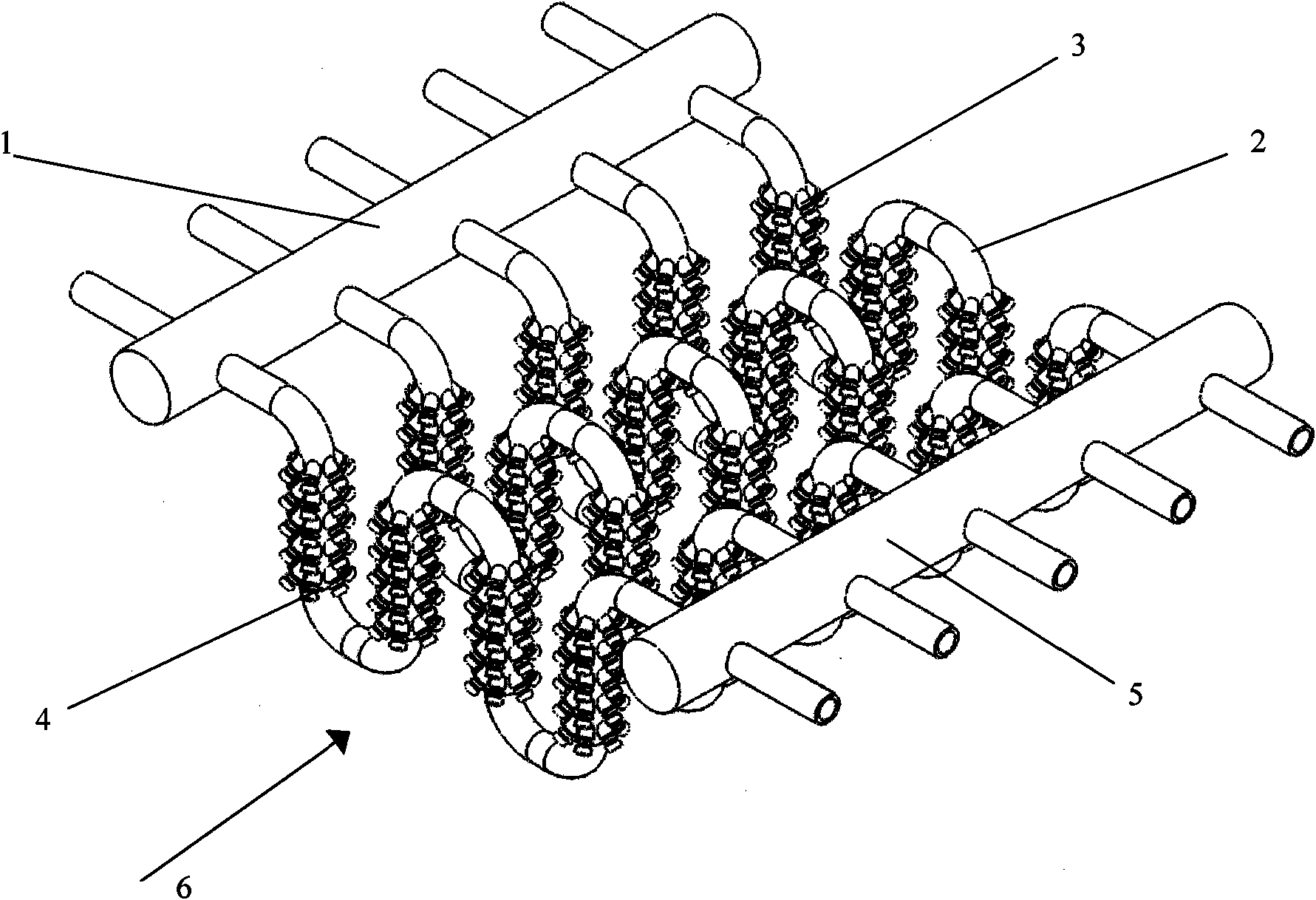

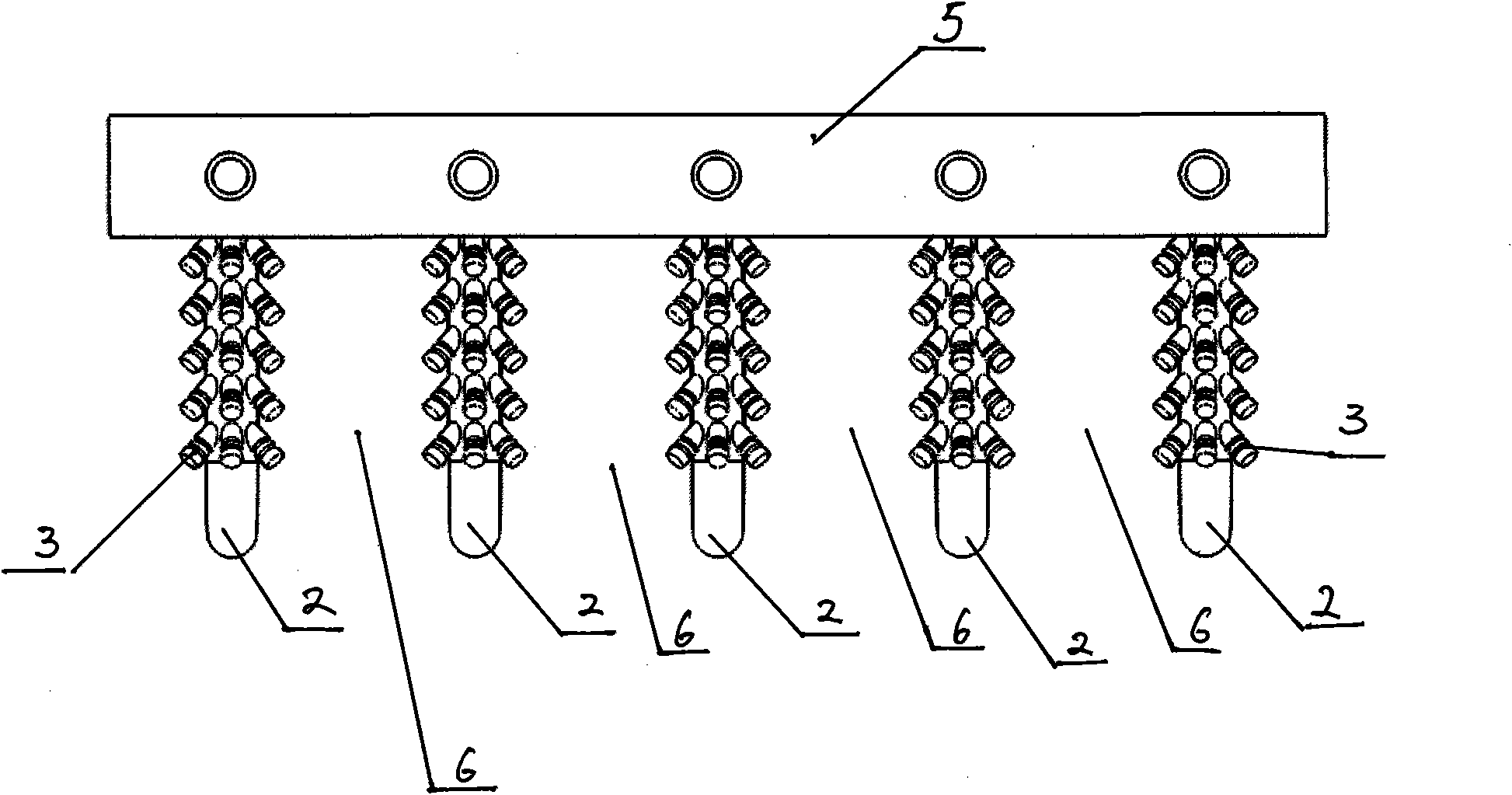

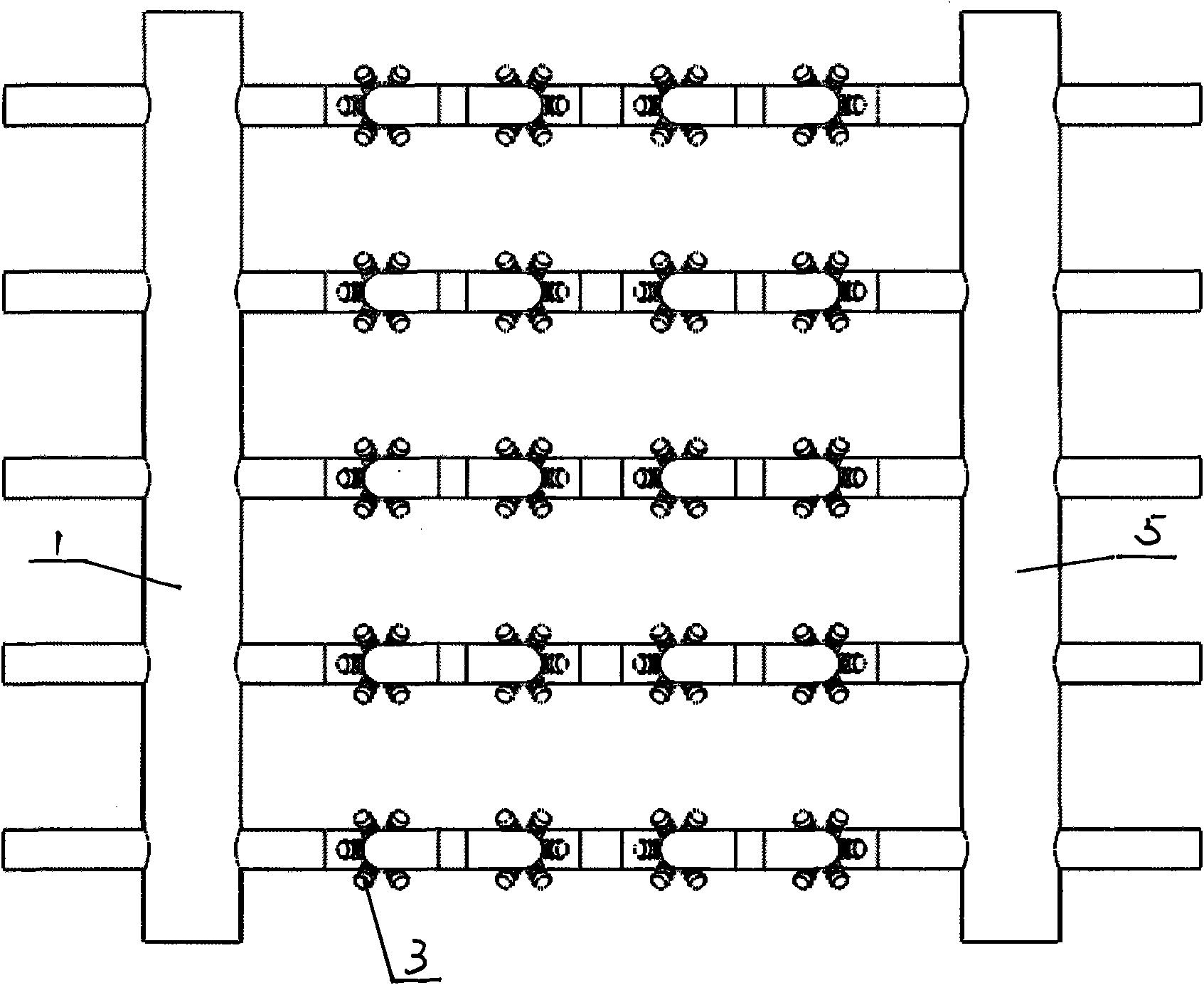

[0019] The invention recycles and utilizes the high-efficiency heat transfer tube of the flue gas waste heat heat exchanger device, which includes an inlet header 1, a serpentine tube 2, a nail tooth rib column 3, an annular groove 4, and an outlet header 5. The whole heat exchanger is a A series of vertical serpentine tubes with spacing arranged side by side, which can be used as heat transfer tubes for waste heat boiler superheaters, evaporators and economizers for recovering waste heat from flue gas, and Located in the inner cavity of the waste heat boiler; the inlet header and the outlet header are arranged outside the waste heat boiler, and the inlet header and the outlet header are provided with connecting holes connected to the serpentine tubes, and the two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com