Measuring device for direct current breakdown voltage of gas discharge tube and method thereof

A technology of DC breakdown voltage and gas discharge tube, which is applied in the direction of discharge tube testing, testing circuit, testing dielectric strength, etc., can solve the large dispersion of driving current and the inability to accurately measure the DC breakdown voltage and driving current of gas discharge tube Major problems, to achieve the effect of improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings.

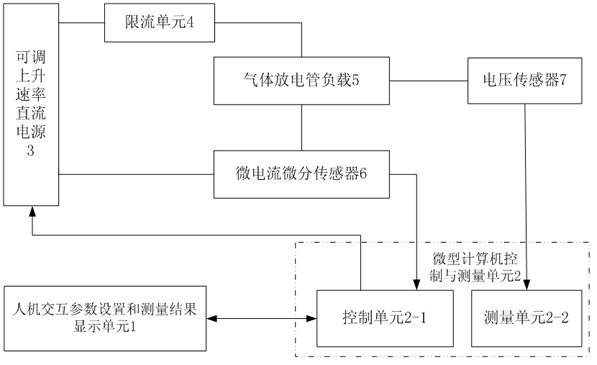

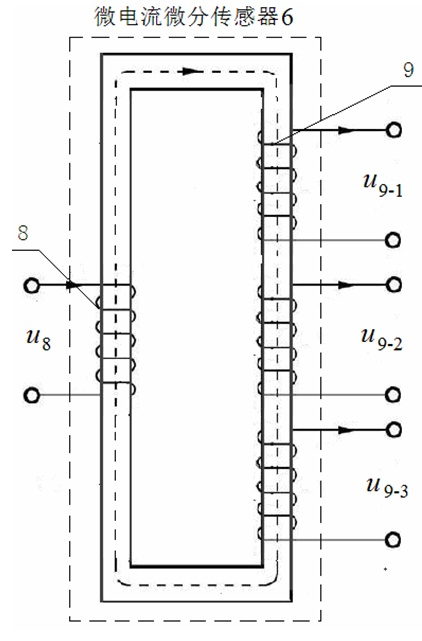

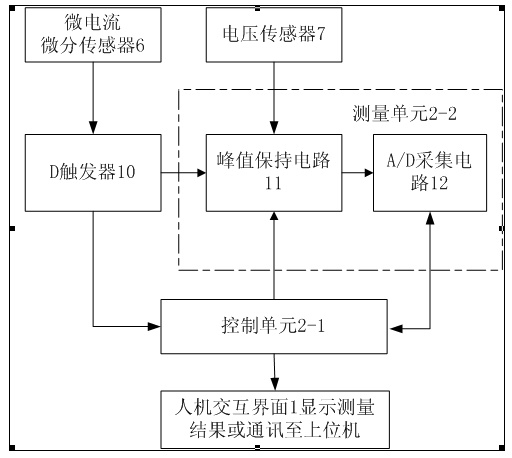

[0023] See figure 1 , The gas discharge tube DC breakdown voltage measurement device of the present invention includes a human-computer interaction parameter setting and measurement result display unit composed of a liquid crystal and a keyboard 1, a microcomputer control and measurement unit 2, an adjustable rise rate DC power supply 3, a current limiting unit 4. Gas discharge tube load 5, micro current differential sensor 6 and voltage sensor 7, human-computer interaction parameter setting and measurement result display unit 1 connected to the microcomputer control and measurement unit 2, the so-called microcomputer control and measurement unit 2 It includes a control unit 2-1 and a measurement unit 2-2 connected to the control unit 2-1, wherein the control unit 2-1 is connected to the adjustable rise rate DC power supply 3, and the high voltage output terminal of the adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com