Strut compound insulator for 126kV outdoor high-voltage alternating current isolating switch

A composite insulator and high-voltage AC technology, applied in the direction of supporting insulators, can solve the problems of poor seismic performance, heavy weight of porcelain insulators, low pollution resistance, etc., achieve stability and verticality improvement, meet the requirements of insulation distance, and improve Effects of Toughness and Seismic Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

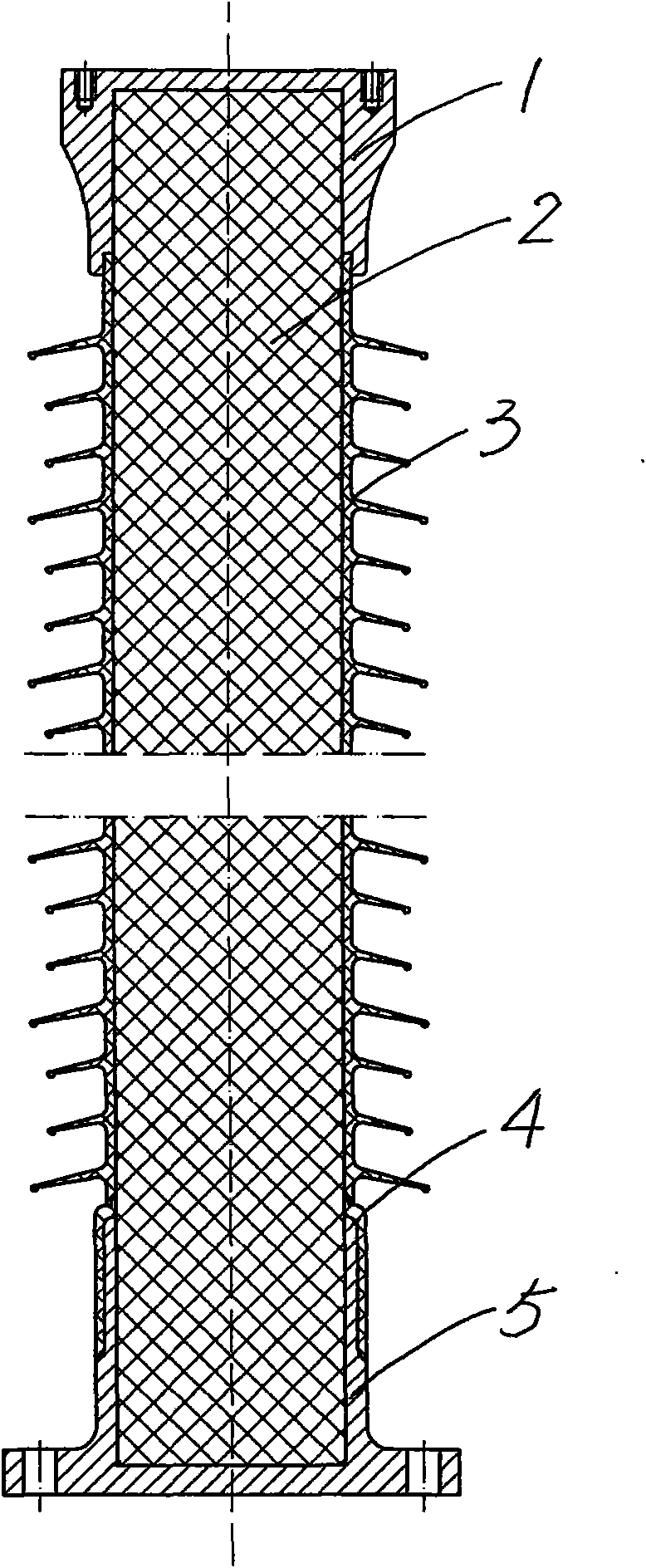

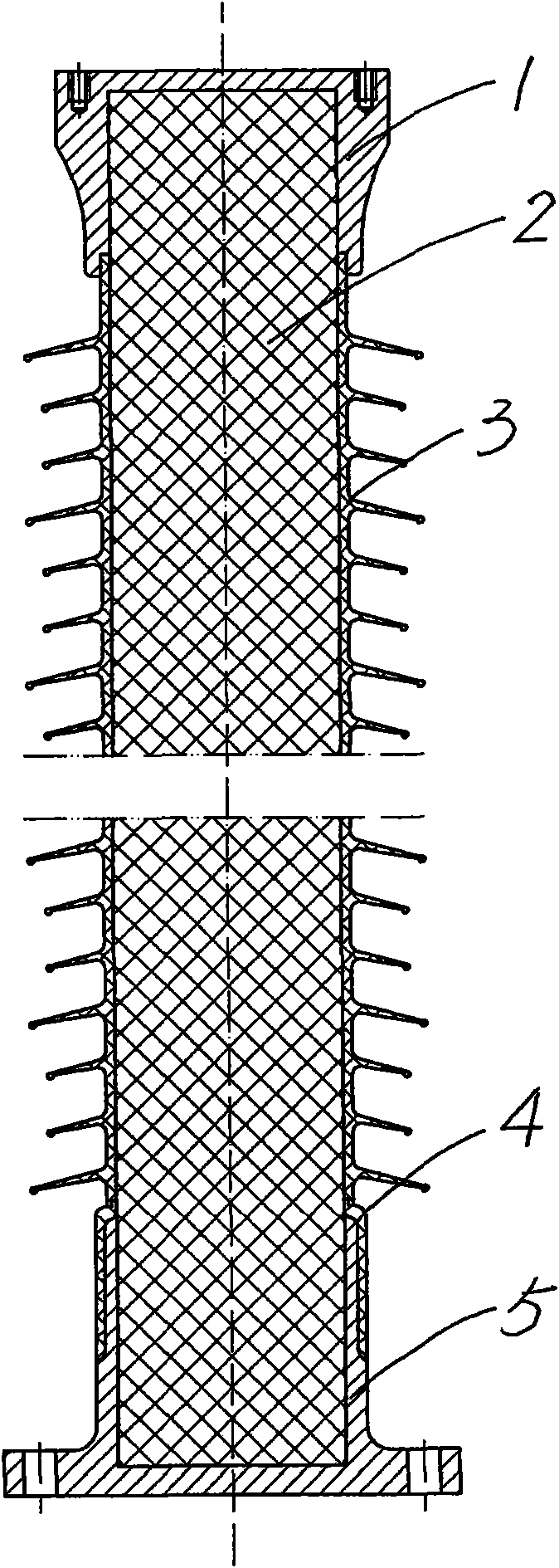

[0013] Referring to the accompanying drawings, the post composite insulator for 126KV outdoor high-voltage AC isolating switch of the present invention includes an upper connecting piece 1, a mandrel 2, an umbrella body 3, a sheath 4, and a lower connecting piece 5, and the upper connecting piece 1 is glued to the mandrel 2, an umbrella body 3 with an integral structure is bonded to the outside of the mandrel 2, the mandrel 2 is a pultruded rod formed by epoxy glass fiber reinforced resin, and the core 2 is impregnated with epoxy resin glue The glass fiber is pultruded into a solid body, and the glass fiber yarn in the mandrel 2 is an uninterrupted glass fiber yarn. The umbrella body 3 is a whole made of high-temperature vulcanized silicone rubber by vacuum injection molding. The high-temperature vulcanized silicone rubber for preparing the umbrella body 3 is composed of methyl vinyl silicone rubber, white carbon black, aluminum hydroxide, silicone oil, and a vulcanizing agent....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com