Method and device for machining inner bending holes of main nuclear power pipeline bend on horizontal boring machine

A technology of horizontal boring machine and main pipeline, which is applied to the parts of boring machine/drilling machine, boring/drilling, metal processing equipment, etc., to achieve the effects of reducing procedures, ensuring processing quality, and improving labor intensity and environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

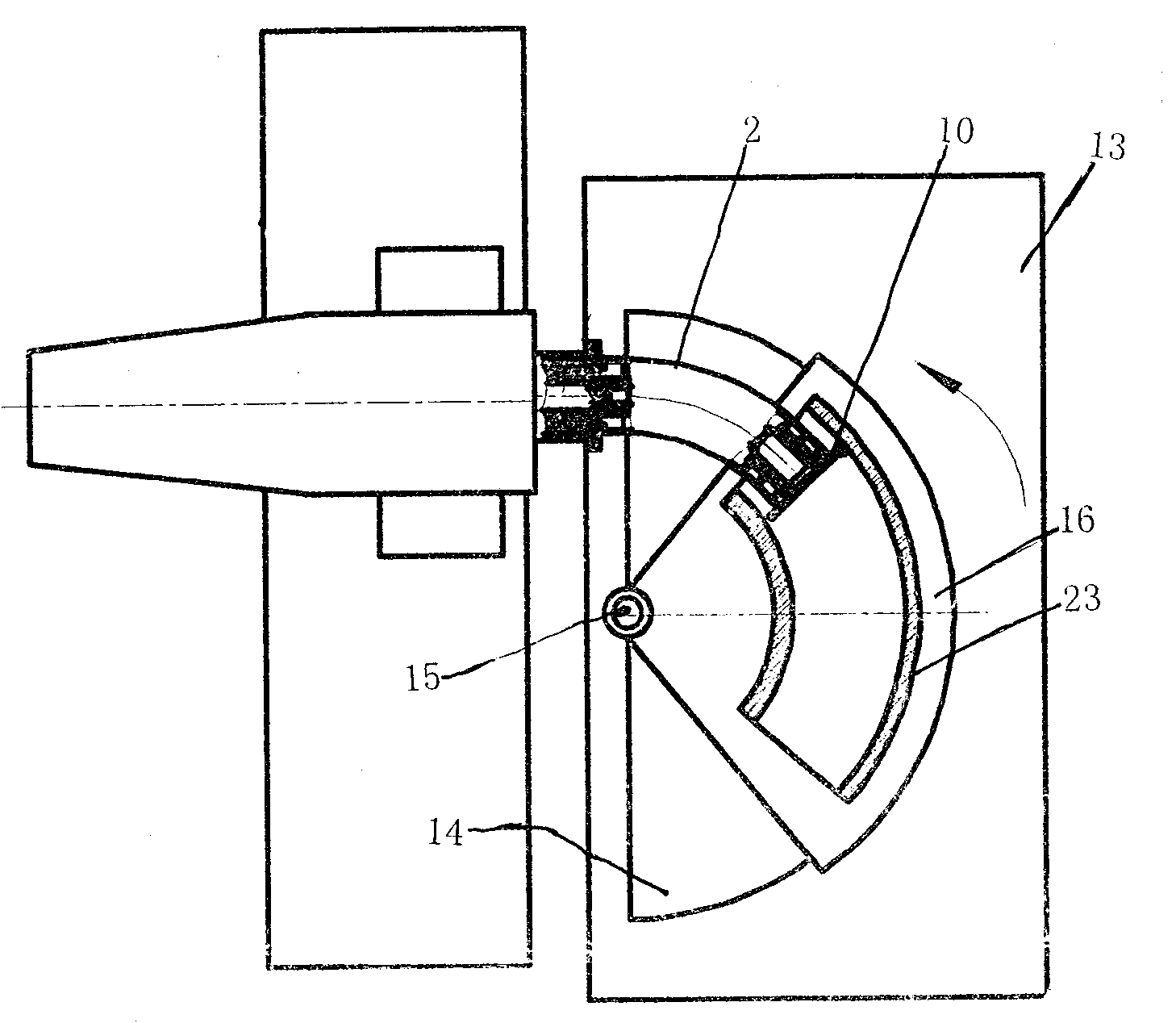

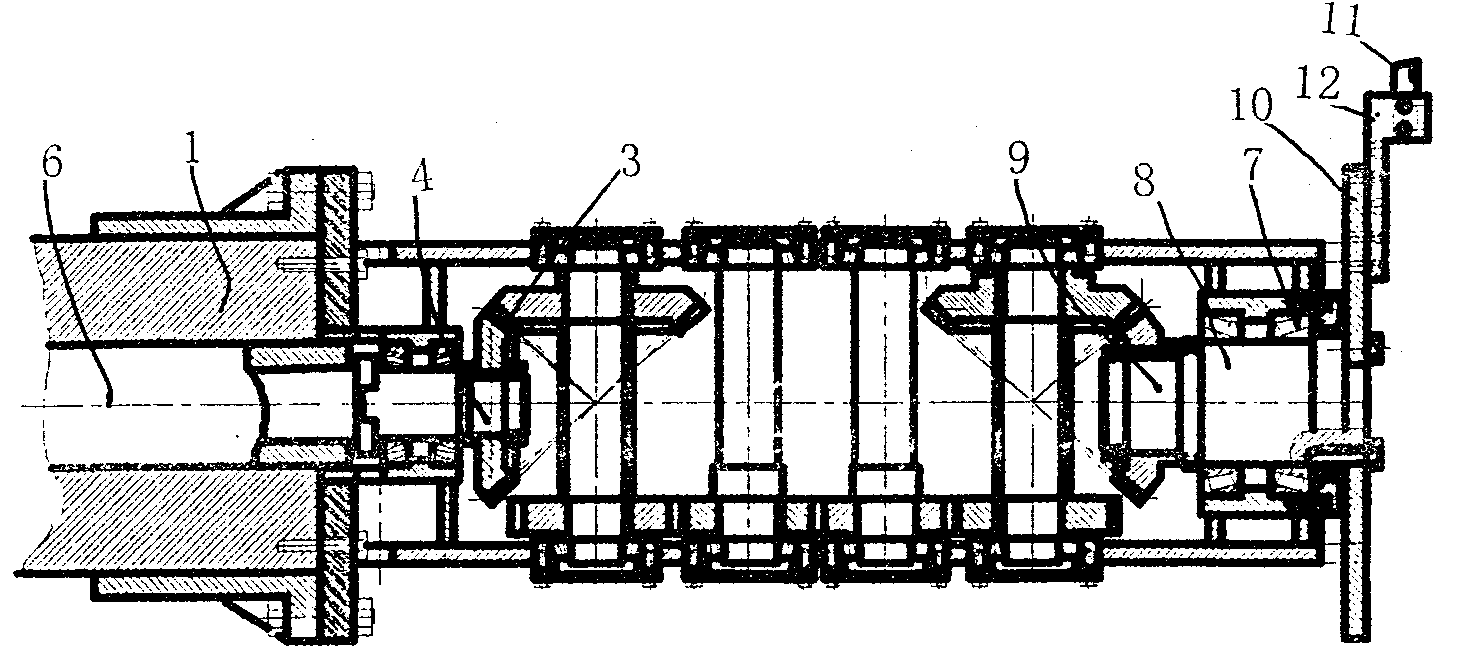

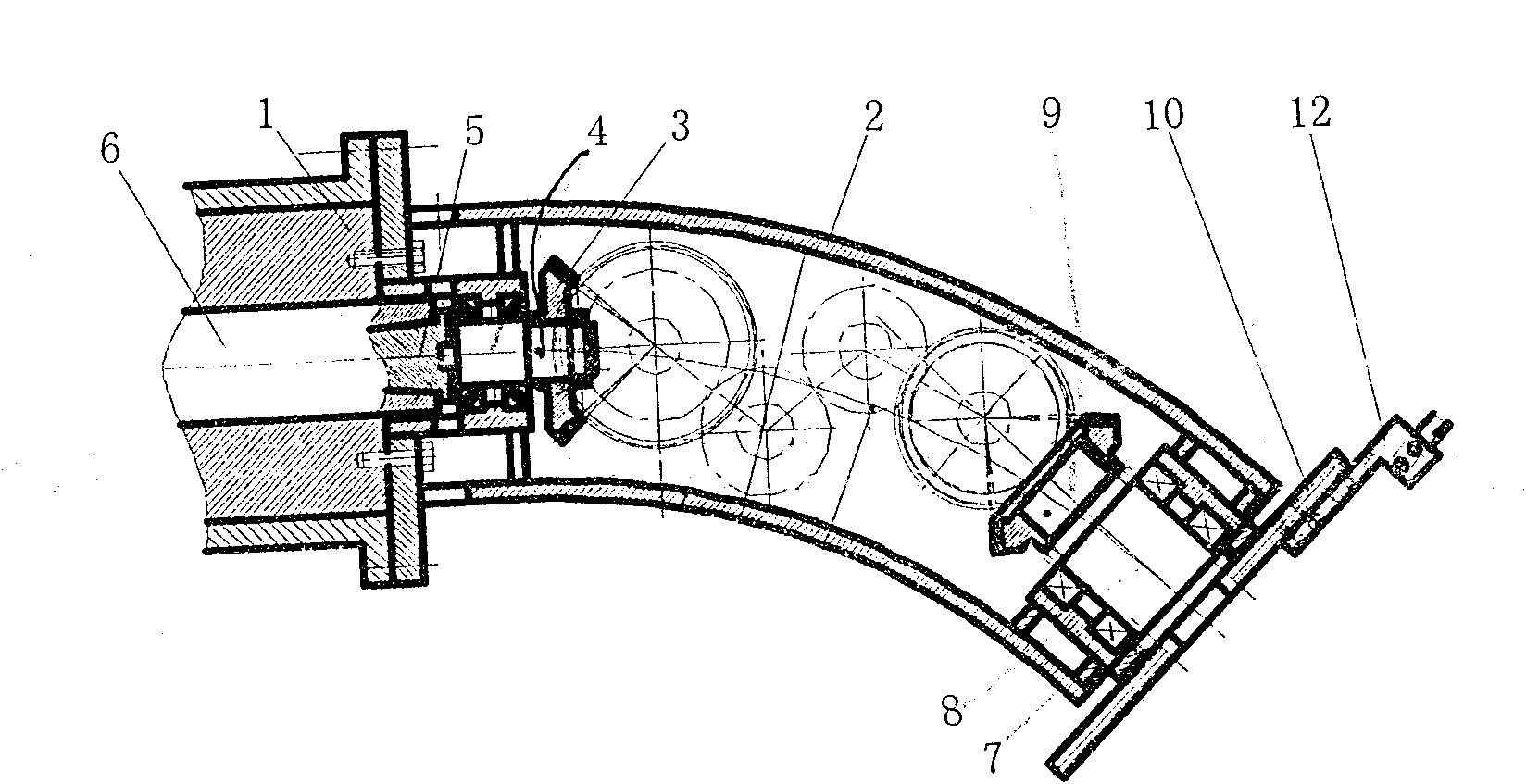

[0054] Figure 1 to Figure 5 A schematic structural diagram of the device for processing the inner hole of a 90° long elbow in Example 1 is given. see Figure 1 to Figure 5 , the device of this embodiment has an arc-shaped cutter housing 2 mounted on the square head 1 of the boring machine at one end, and one end of the driving bevel gear shaft 4 in the power transmission and steering mechanism 3 in the arc-shaped cutter housing is mounted on the taper handle 5 of the boring machine and passed through The taper handle of the boring machine is driven by the main shaft 5 . There is support 7 with bearing in the other end of the arc-shaped cutter housing, and one end of boring bar 8 stretches into the support and is integrated with the driven bevel gear shaft 9 in the power transmission and steering mechanism so as to be driven by the power transmission and steering mechanism. The curved shell has a bending radius of 1300 mm. Boring bar one end is equipped with cutter head 10,...

Embodiment 2

[0062] Figure 4 ~ Figure 6 A schematic structural diagram of the device in Example 2 is given. The device in Embodiment 2 is basically the same as that in Embodiment 1, except that the boring bar is a straight boring bar directly installed in the taper hole of the main shaft. Reinforcing sleeve 24 is housed on the boring bar. This device can process the inner holes of short elbows such as 28°22′, 40°, 50°, etc.

[0063] The method steps for processing the inner holes of short elbows such as 28°22′, 40°, 50°, etc. are as follows:

[0064] (1) Install the rotary table on the boring machine table, place the elbow of the workpiece on the rotary table, make the center of the bending radius of the elbow coincide with the center of rotation, align and compress.

[0065] (2) The boring bar is installed on the main shaft of the boring machine, the boring bar and the cutter head rotate, and the cutter head is used to draw a circle with the end face of the elbow to find the circle. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com