Underwater cavitating cleaner for ship

A technology for cleaning devices and ships, applied in ship cleaning devices, ship hulls, ship construction, etc., can solve the problems of secondary pollution, divers and environmental hazards, low efficiency, etc., and achieve the effect of high cleaning efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

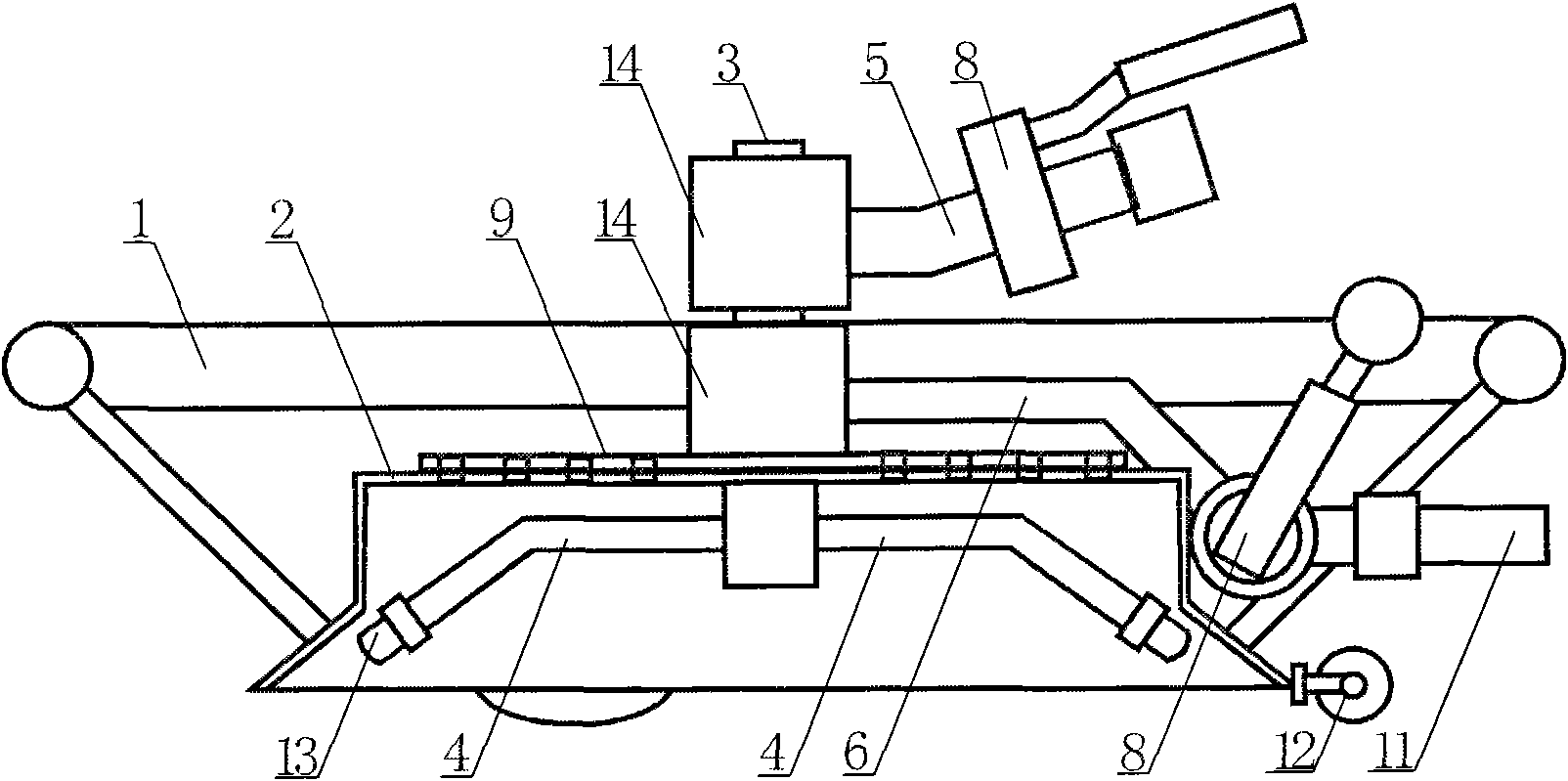

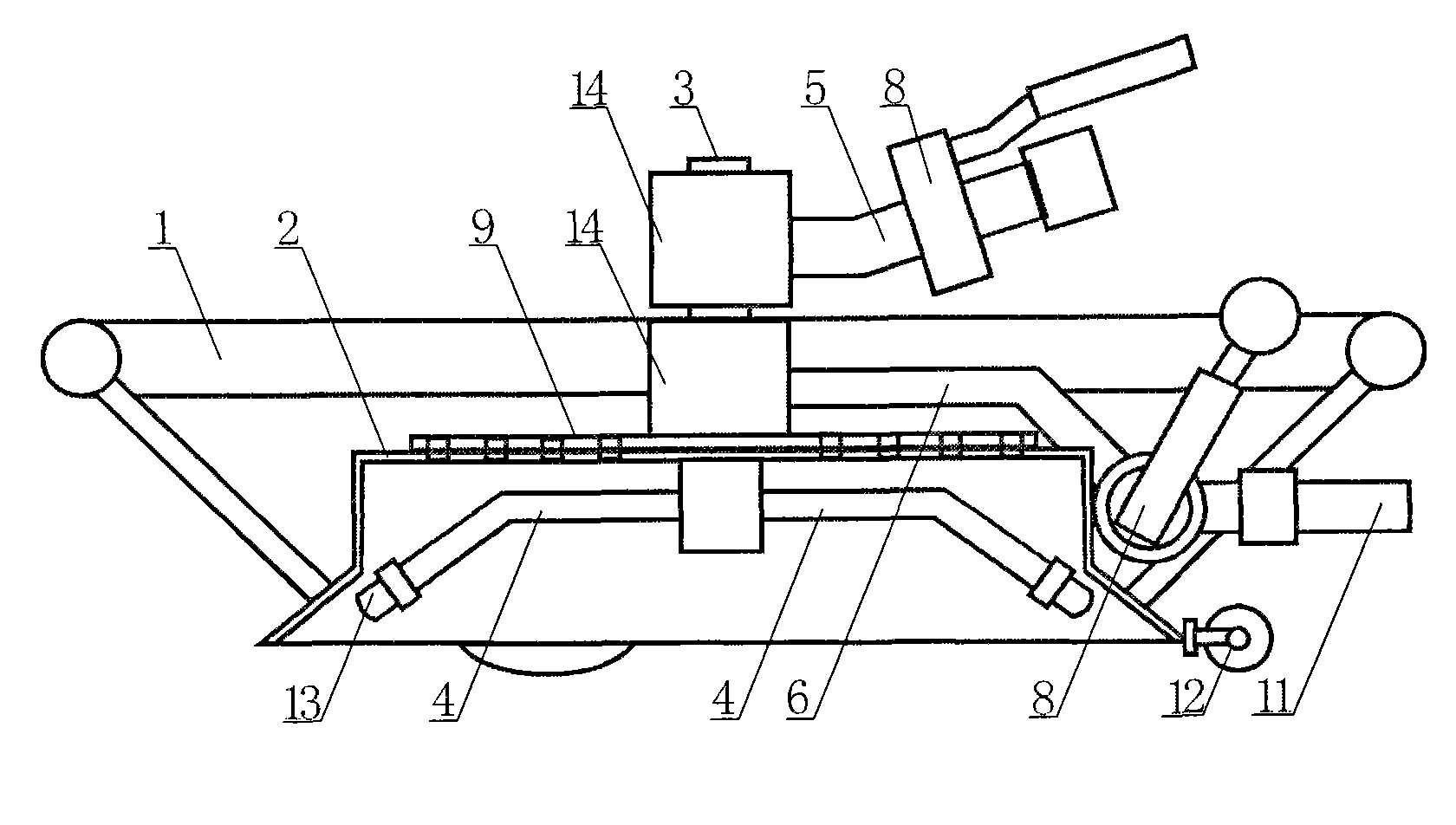

[0015] Such as figure 1 As shown, the ship's underwater cavitation cleaning device is composed of a push handle frame 1, a disc-shaped housing 2, a hollow shaft 3, a cleaning nozzle 4, a high-pressure liquid input pipe 5 and a propulsion nozzle 6. The top of the casing 2 is provided with a plurality of water inlets, the push handle frame 1 is arranged on the top of the disk-shaped casing 2 and connected with the disk-shaped casing 2, and one end of the hollow rotating shaft 3 passes through the central hole of the disk-shaped casing 2 There are 3 spray pipes 4 for cleaning, and each spray pipe 4 for cleaning is arranged in the disk-shaped housing 2 and communicates with the hollow rotating shaft 3, and the end of the spray pipe 4 for cleaning is provided with a turbine nozzle 13; The liquid input pipe 5 and the propulsion nozzle 6 communicate with the hollow rotating shaft 3 respectively through the connecting piece 14 and are located above the disk-shaped housing 2. The conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com