Thermal insulation roof board with combined structure

A technology of thermal insulation roof panels and combined structures, which is applied to roofs, roofs using flat/curved panels, roof cladding, etc., which can solve the problems of unguaranteed bonding between the surface layer and the core material, unsuitable promotion and use, and high comprehensive production costs. problems, to achieve good thermal insulation and energy saving effects, simple and convenient construction and assembly, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

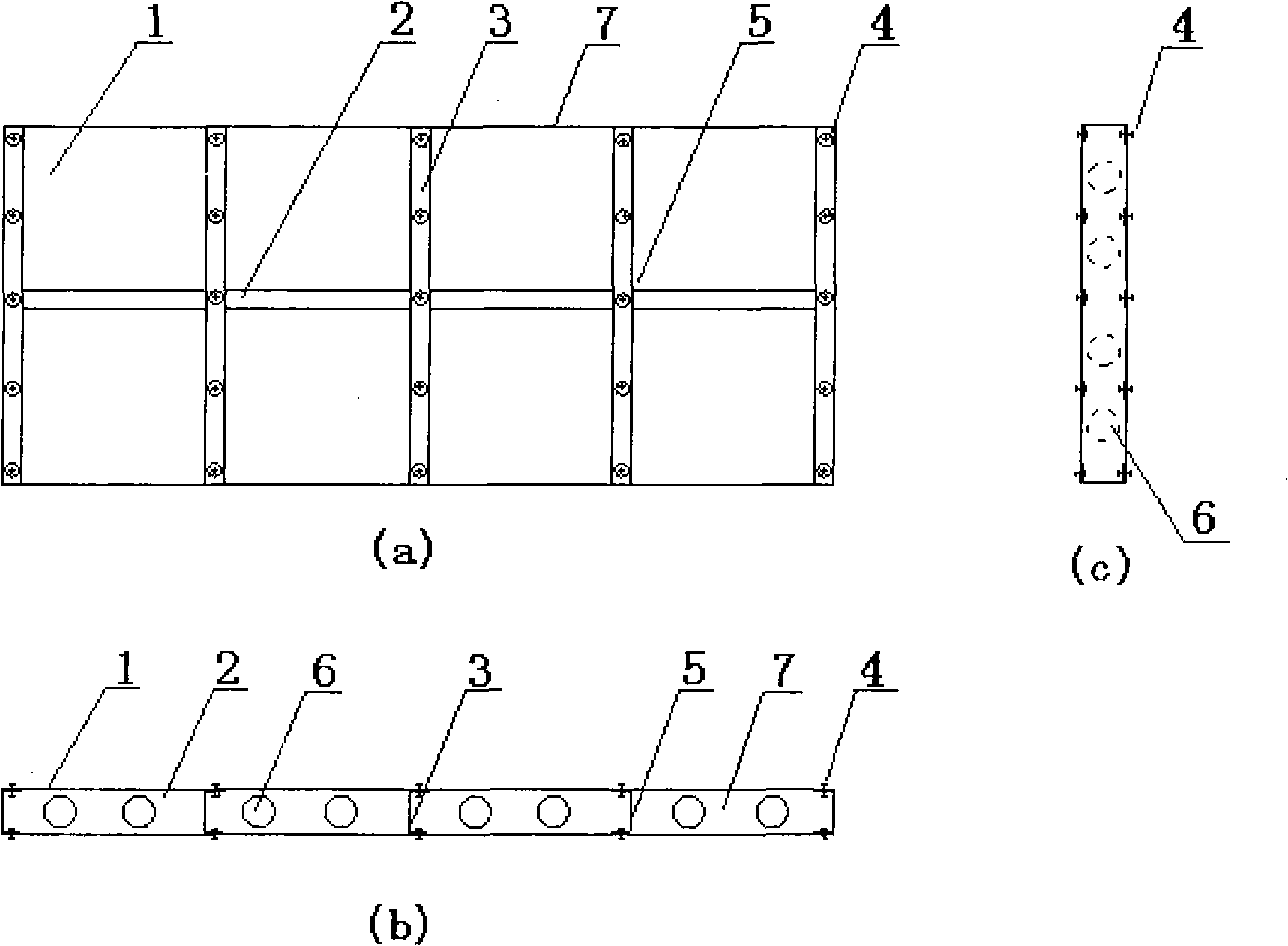

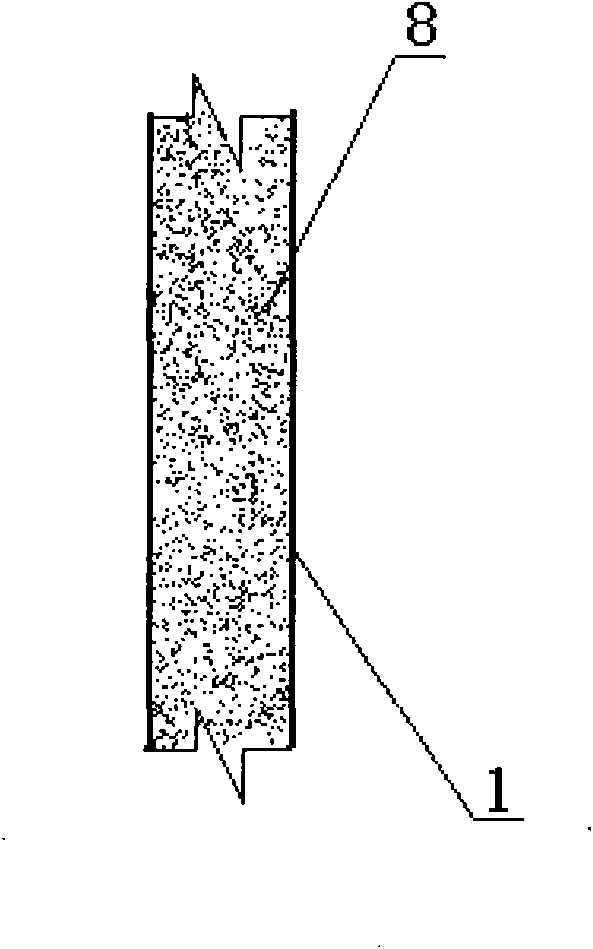

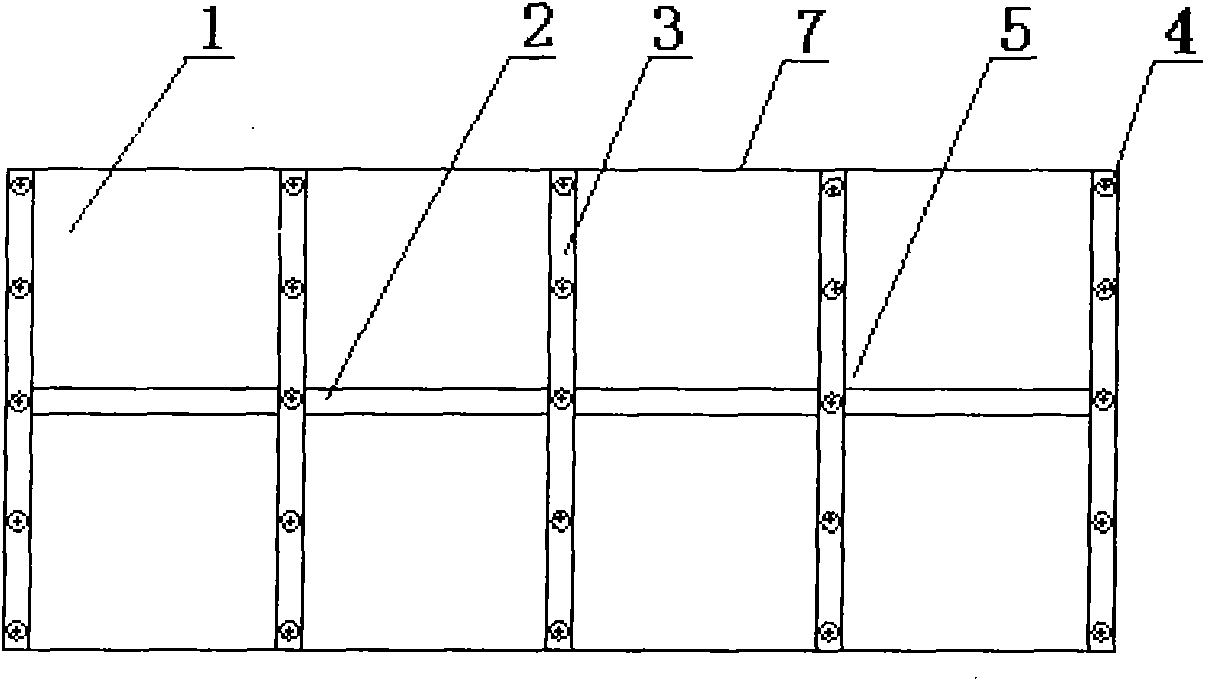

[0022] Example 1: Straw foam concrete combination thermal insulation roof panel

[0023] The thickness of the light steel keel plate is 0.4mm, the width of the web is 60mm, and the width of the flange is 33mm. The keel is reserved with connecting holes, and the rib keel is provided with reserved perforations. The building formwork mesh is made of template mesh, the thickness of the steel plate is 0.4mm, the hole type is 3.5*10mm, and it is cut into the required size of the plate. The spine keel is connected to the rib keel through the reserved perforation to form a keel frame, and one side of the mesh is connected to the keel frame through self-tapping nails. The side with the mesh facing down, lay it horizontally on the molding table.

[0024] Straw foam concrete (compressive strength not less than 1.5MPa, consistency 100mm) is mixed with raw materials such as 25mm straw fiber, plant composite foaming agent, and rapid hardening cement, and directly and evenly poured into eac...

Embodiment 2

[0026] Example 2: Rigid foamed polyurethane composite thermal insulation roof panel

[0027] The thickness of the light steel keel plate is 0.4mm, the width of the web is 60mm, and the width of the flange is 33mm. The keel is reserved with connecting holes, and the rib keel is provided with reserved perforations. The building formwork mesh is made of template mesh, the thickness of the steel plate is 0.4mm, the hole type is 3.5*10mm, and it is cut into the required size of the plate. The spine keel is connected to the rib keel through the reserved perforation to form a keel frame, and the mesh on both sides is connected to the keel frame by self-tapping screws to form a structure.

[0028] Two-component rigid foamed polyurethane material is used, and the special pouring equipment is directly and evenly poured into the cavity of the structure through the injection port of the insulation body. After standing for 1 hour, move it into the warehouse for storage.

[0029] The meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com